Equipment for quantum dot test paper quality inspection and use method of equipment

A technology of test strips and quantum dots, which is applied in the field of quality inspection equipment for quantum dot test strips, can solve problems such as inability to guarantee product consistency and product quality stability, and achieve accurate and reliable test results, consistency and quality assurance Stability and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The present invention will be further described in conjunction with the above drawings.

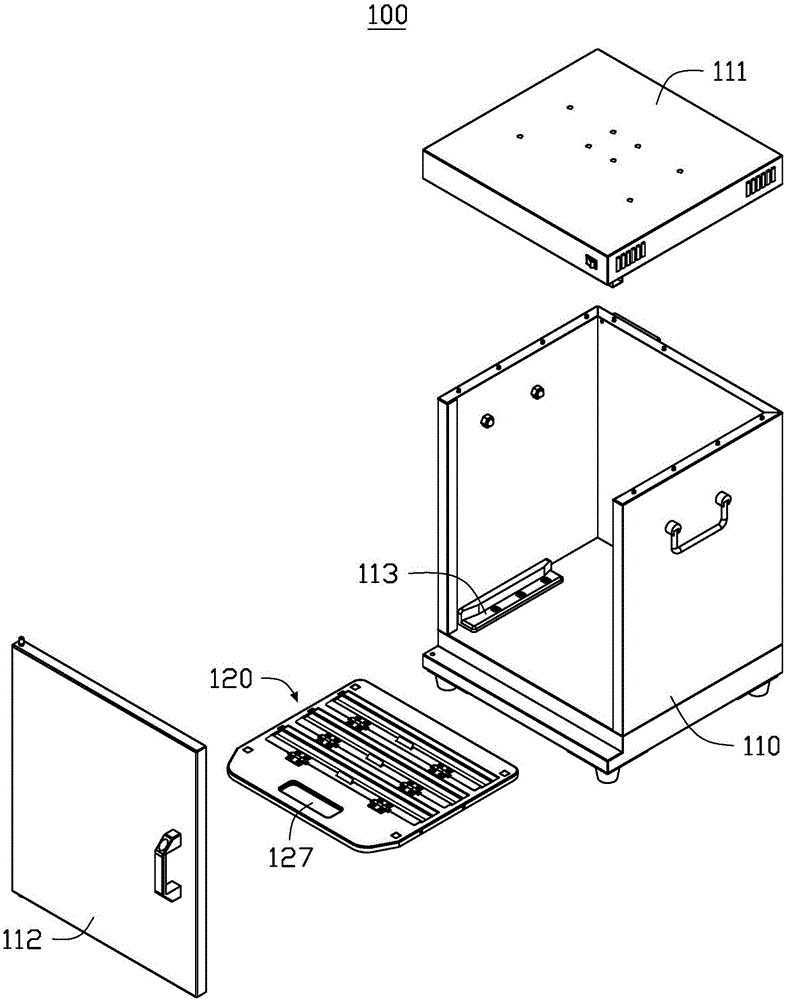

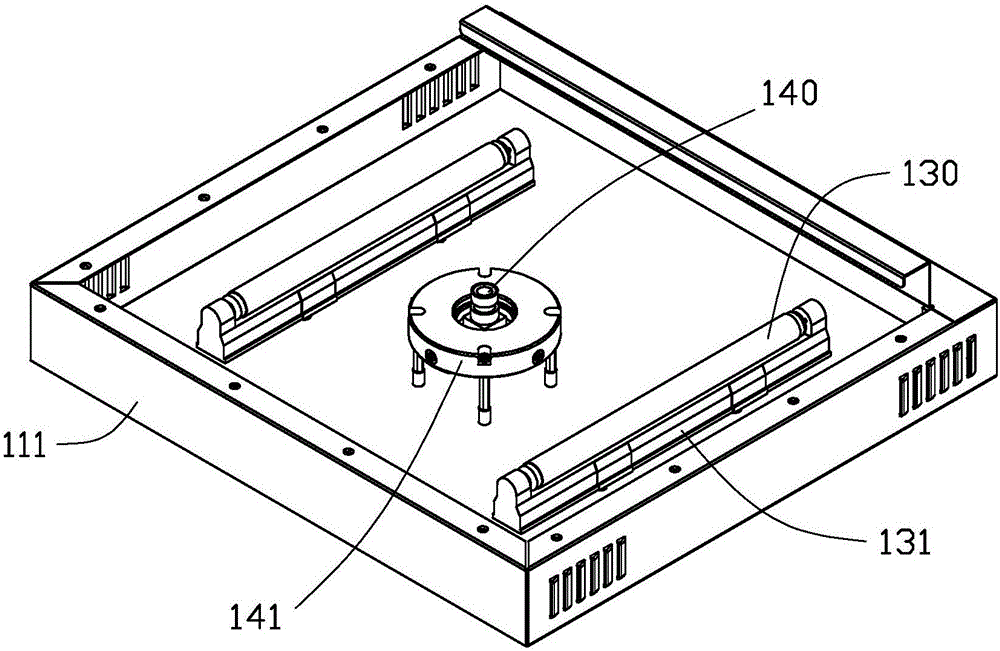

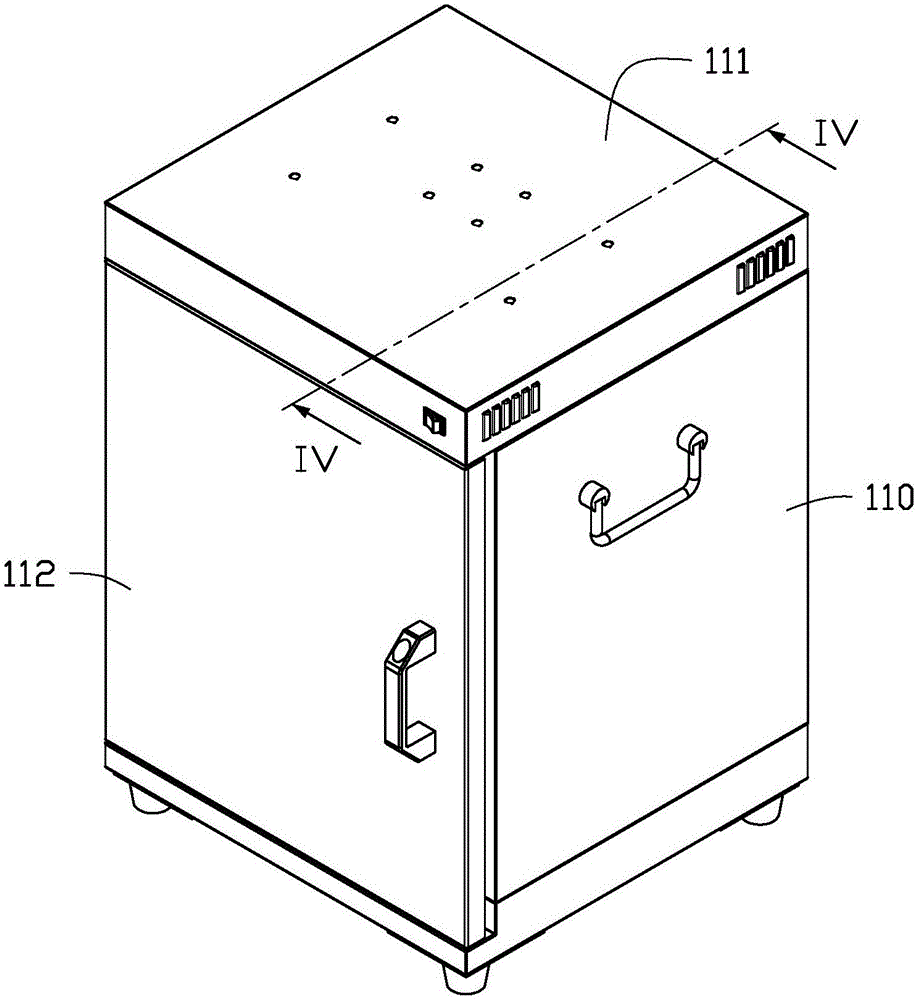

[0059] Such as Figure 1-5 As shown, the equipment 100 for quality inspection of quantum dot test strips according to the first preferred embodiment of the present invention includes: a dark box 110 , a supporting device 120 , a light source device 130 , and a signal acquisition device 140 .

[0060] The dark box 110 includes a detachable top plate 111 , a door 112 that can be opened and closed, and a chute 113 is provided at the bottom of the dark box 1 .

[0061] The supporting device 120 is engaged on the bottom of the dark box 112 through the slide groove 113 , and includes a strip groove 121 , a scale area 122 and a reference area 123 . In this embodiment, the supporting device 120 is a tray.

[0062] The strip groove 121 is used to place a quantum dot test strip 124 . In this embodiment, the number of bar-shaped grooves 121...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com