Probe replacement device and method and test device

A probe and probe box technology, applied in the field of testing, can solve the problems of inaccurate test results, damage, large test errors, etc., and achieve the effects of improving test accuracy, improving replacement efficiency, and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

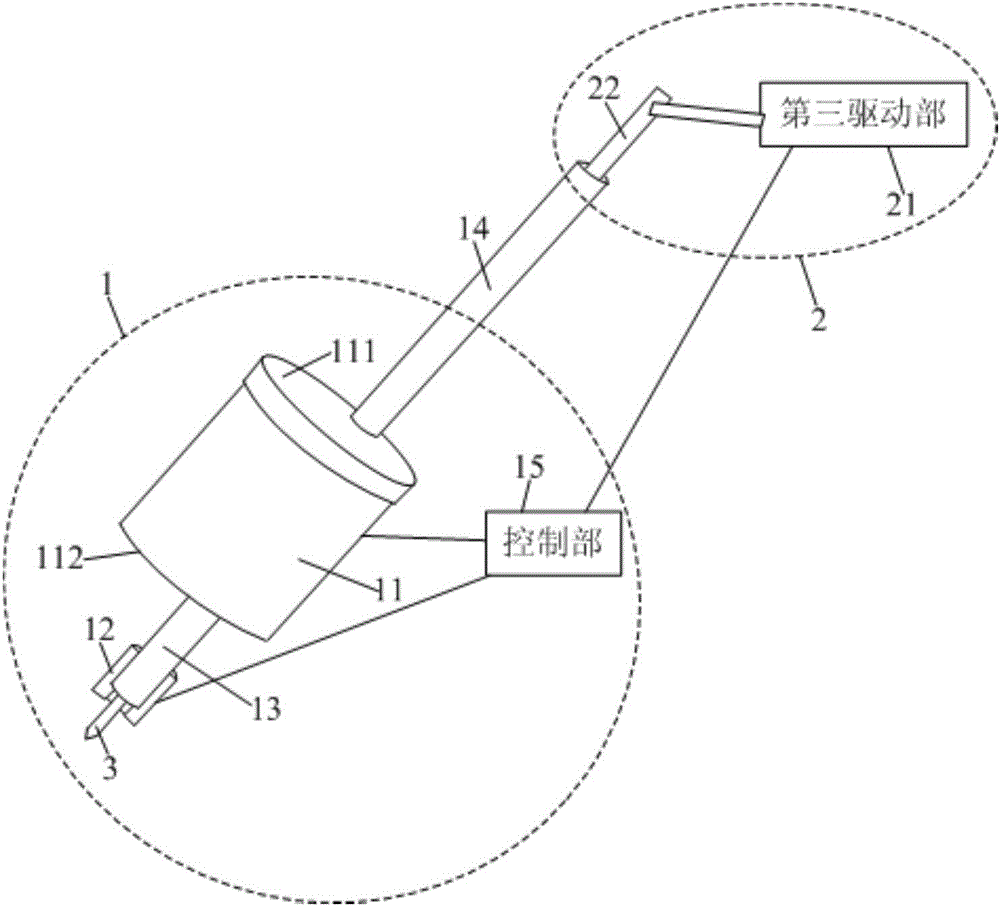

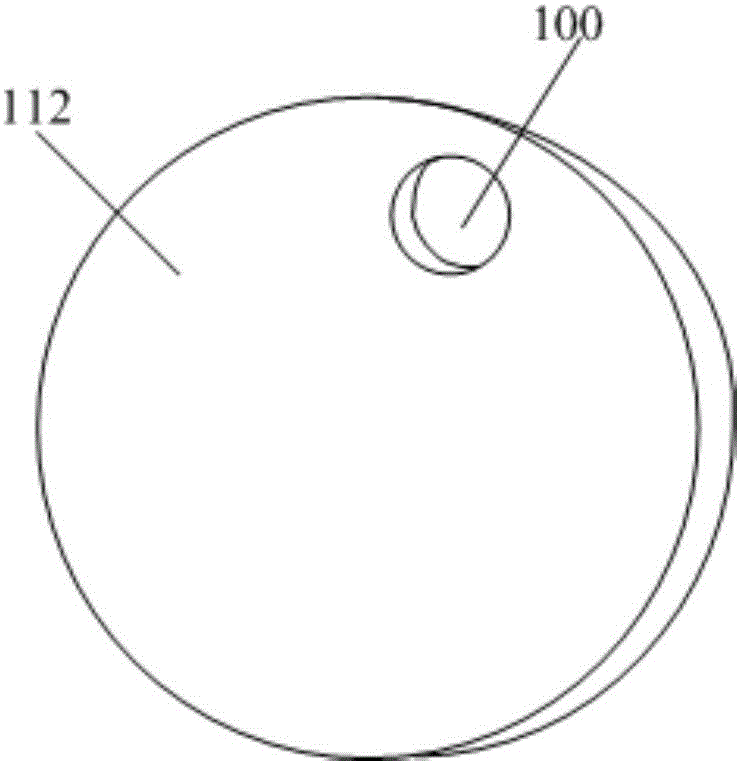

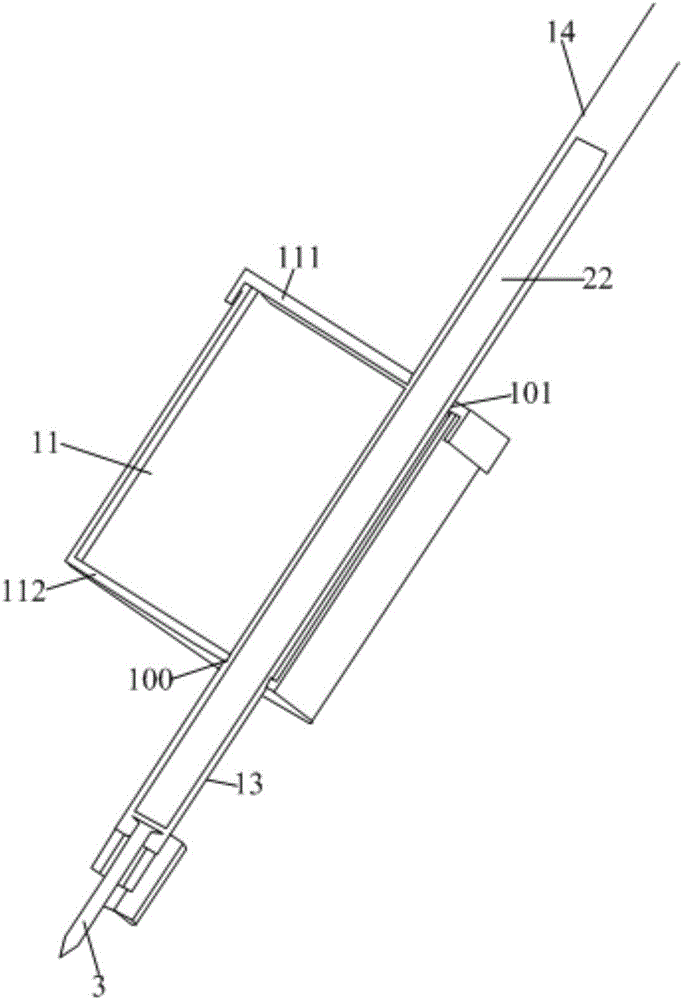

[0051] This embodiment provides a probe replacement device, such as figure 1 As shown, it includes a replacement mechanism 1 and an auxiliary mechanism 2. The replacement mechanism 1 is used to replace the probe 3; the auxiliary mechanism 2 is used to assist the replacement mechanism 1 to push the spare probe 3 to the replacement position.

[0052]The replacement position refers to the fixed position of the probe 3 during testing. When the probe 3 in use is damaged, the replacement mechanism 1 will replace the probe 3 at the replacement position.

[0053] By setting the replacement mechanism 1 and the auxiliary mechanism 2, the automatic replacement of the probe 3 can be realized. The automatic replacement can keep the probe 3 clean and the position is accurate during the replacement process, thereby avoiding the probe caused by manual replacement. 3 is stained with foreign matter and the position of the replaced probe 3 is inaccurate, which reduces the test error of the probe...

Embodiment 2

[0087] This embodiment provides a testing device, including the probe replacement device in Embodiment 1.

[0088] By adopting the probe replacement device in Embodiment 1, the testing equipment can realize automatic replacement of probes, thereby not only improving the testing accuracy, but also improving the testing efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com