Bracket, backlight module and liquid crystal display device

A backlight module and bracket fixing technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of difficult disassembly, long time consumption, etc., and achieve the effect of simple operation, short time consumption, fast installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

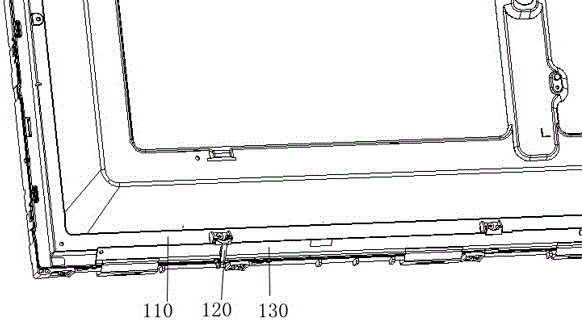

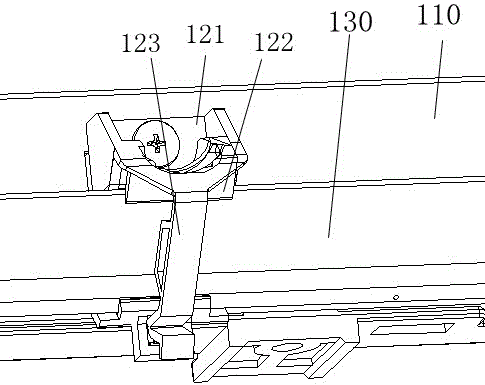

[0039] Embodiment 1 of the present invention provides a bracket fixing member and a backlight module. The backlight module can be applied to the fixing of functional brackets in any liquid crystal display device. For the convenience of description, the embodiment 1 of the present invention selects the fixing scheme of the Source board for illustration. Figure 5 It is a structural schematic diagram of the backlight module in Embodiment 1 of the present invention.

[0040] It should be noted that, in addition to the backlight module provided in Embodiment 1 of the present invention Figure 5~Figure 14 In addition to the structure shown, it also includes at least a light source, a plastic frame, a light guide plate, and other optical films. Regarding other components of the backlight module in this embodiment 1, the present invention does not specifically limit it. Those skilled in the art can refer to existing There is a specific structure of the backlight module in the art. ...

Embodiment 2

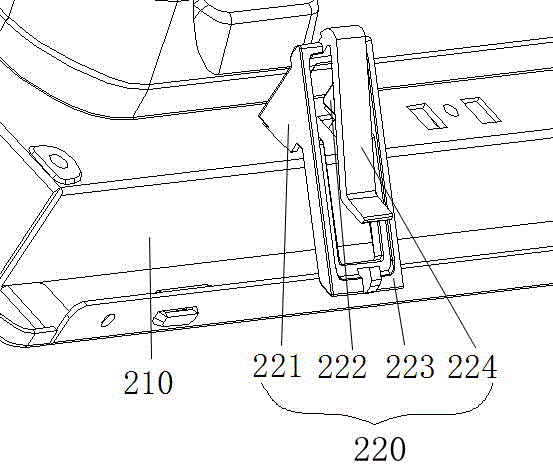

[0099] It should be noted that the Source plate support provided in Embodiment 1 of the present invention can also be transformed into other functional supports, such as a diffuser plate support.

[0100] Specifically, such as Figure 15 As shown, the diffuser plate support includes a base 710 and a support portion 720 . The base 710 is connected with the supporting part 720 as a whole, and the base 710 is used to be fixed on the backplane of the backlight module. The specific fixing method is as described in the connection method between the locking part of the backplane and the backplane in Embodiment 1, and there is no need to do too much here repeat.

[0101] The support part 720 is used to support the diffuser plate. Specifically, the diffuser plate is installed on the upper surface of the support part 720. The support part 720 is used to support the diffuser plate. The upper surface of the support part 720 and the diffuser plate are in surface contact.

[0102] In the ...

Embodiment 3

[0108] Embodiment 3 of the present invention provides a liquid crystal display device, comprising a liquid crystal display panel and the backlight module described in Embodiment 1 above. Wherein, the backlight module and the liquid crystal display panel are at opposite positions, and the liquid crystal display panel is located on the upper surface of the backlight module; the structure, function and effect of the backlight module have been described in detail in the foregoing embodiments, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com