Injection molding machine capacity acquisition system

A collection system and injection molding machine technology, applied in the field of information collection, can solve problems such as the inability to understand the production dynamics of injection molding machines in real time, the inability to intuitively understand the production site status, and the lag of production capacity reports, so as to facilitate large-scale promotion and use, and the data is true. Reliable, time-sensitive results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

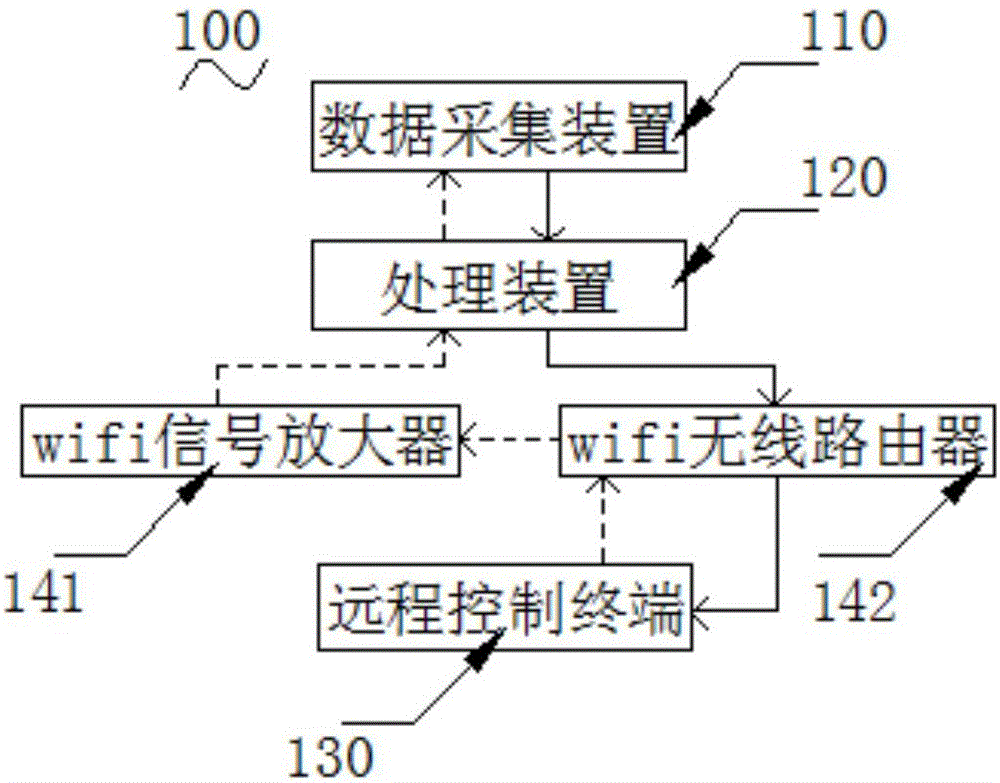

[0031] Such as figure 1 Shown is the structural representation of the present invention.

[0032] The production capacity acquisition system 100 of the injection molding machine includes a data acquisition device 110 for collecting various parameters of the injection molding machine and environmental parameters, a processing device 120 for processing the collected data, a remote control terminal 130 for remote control, and The communication device 140 communicates between the processing device 120 and the remote control terminal 130 .

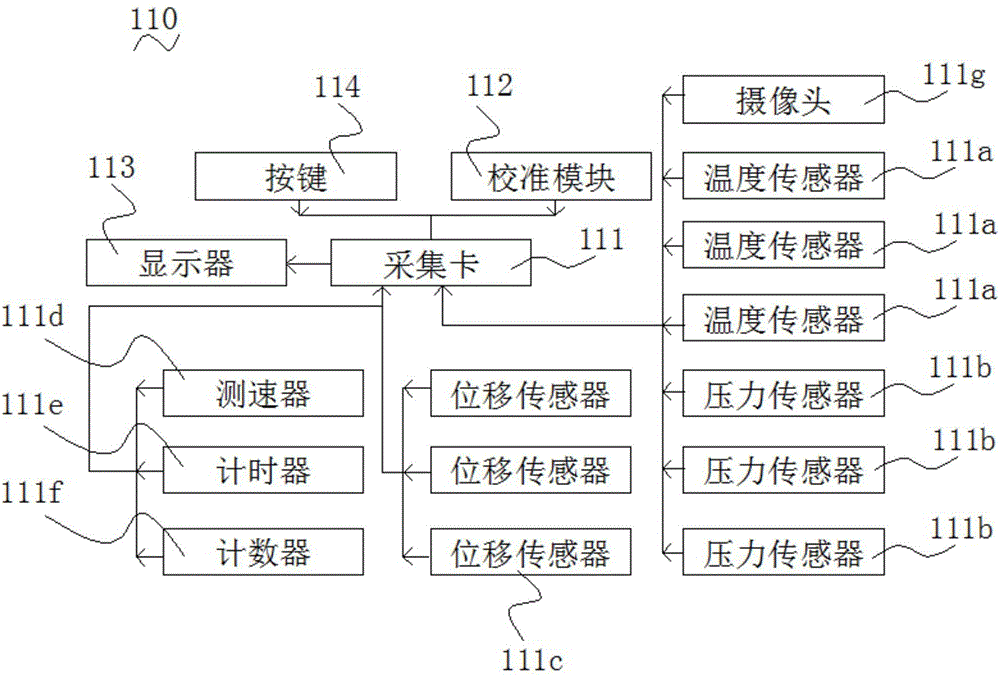

[0033] Such as figure 2 Shown is a schematic structural diagram of the data acquisition device of the present invention.

[0034] The data collection device 110 includes a collection card 111 connected to the injection molding machine PLC to collect various data, a calibration module 112 for calibrating the collection module, a disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com