Chip welding pressure block assembly

A chip welding and block assembly technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of affecting the pressure accuracy and welding effect, quantitative control of welding pressure, and long process realization cycle. Simple structure, high working stability and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

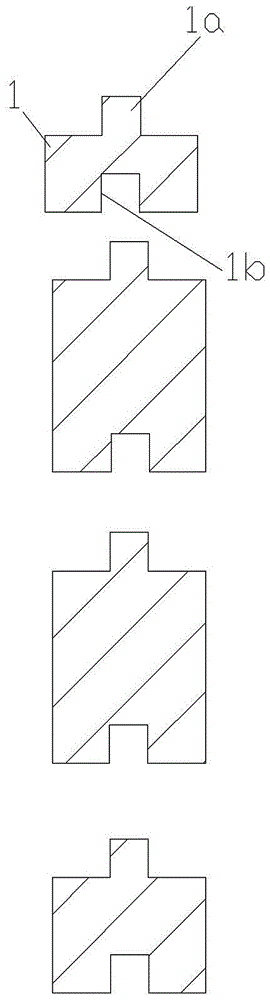

[0027] Such as Figure 1-6 As shown, a chip bonding compact assembly includes a group of compacts 1, each of which has the same bottom surface area and bottom shape, and the group of compacts 1 can be cylindrical or cubic or cuboid.

[0028] A tenon 1a is provided on the top of each pressing block 1, and a slot 1b corresponding to the tenon 1a is provided on the bottom of each pressing block 1. Threads are provided on the mortise 1a and the socket 1b, and several pressure blocks can be connected together through the threads so as to provide different pressures.

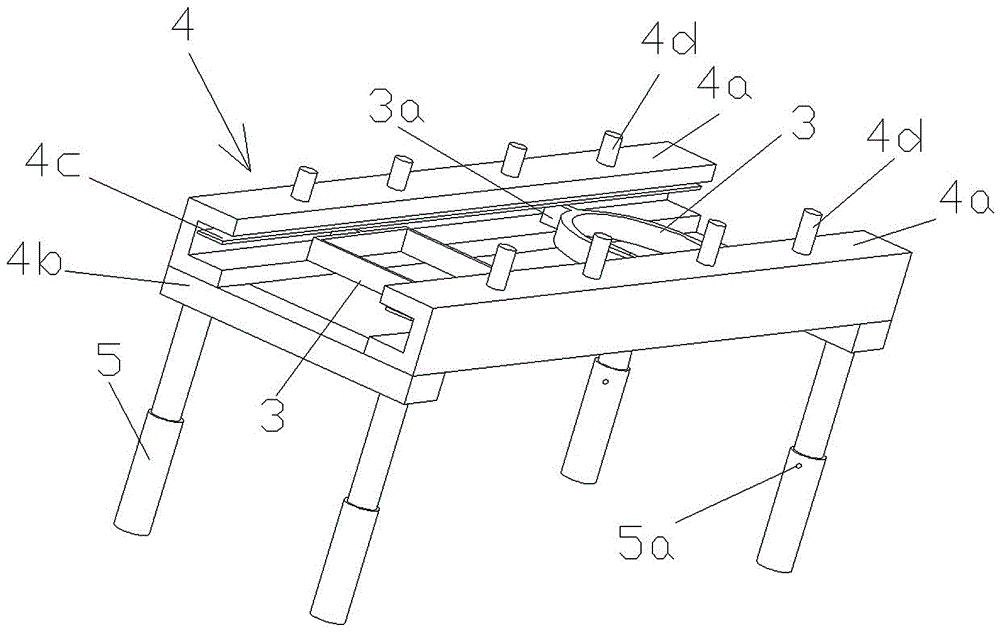

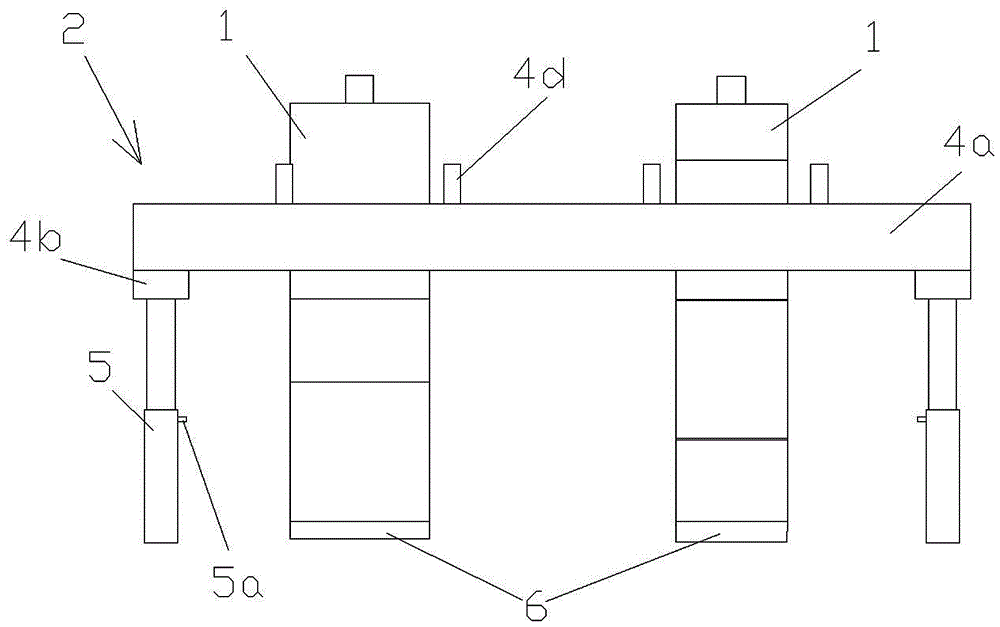

[0029] A stabilizer 2 is set, and the stabilizer 2 is composed of a frame body 4 and a group of frame legs 5, the frame body 4 includes a pair of channel steel 4a arranged in parallel, and the pair of channel steel 4a The notches are set relative to each other. On the channel wall on one side of the channel steel 4a, a group of vertically distributed locking bolts 4d are arranged along its length. The platen 4c. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com