Method for Automatic Monitoring of Film Thickness Uniformity

A technology with uniform film thickness and automatic monitoring. It is used in instruments, semiconductor/solid-state device testing/measurement, measurement devices, etc., and can solve problems such as abnormal product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

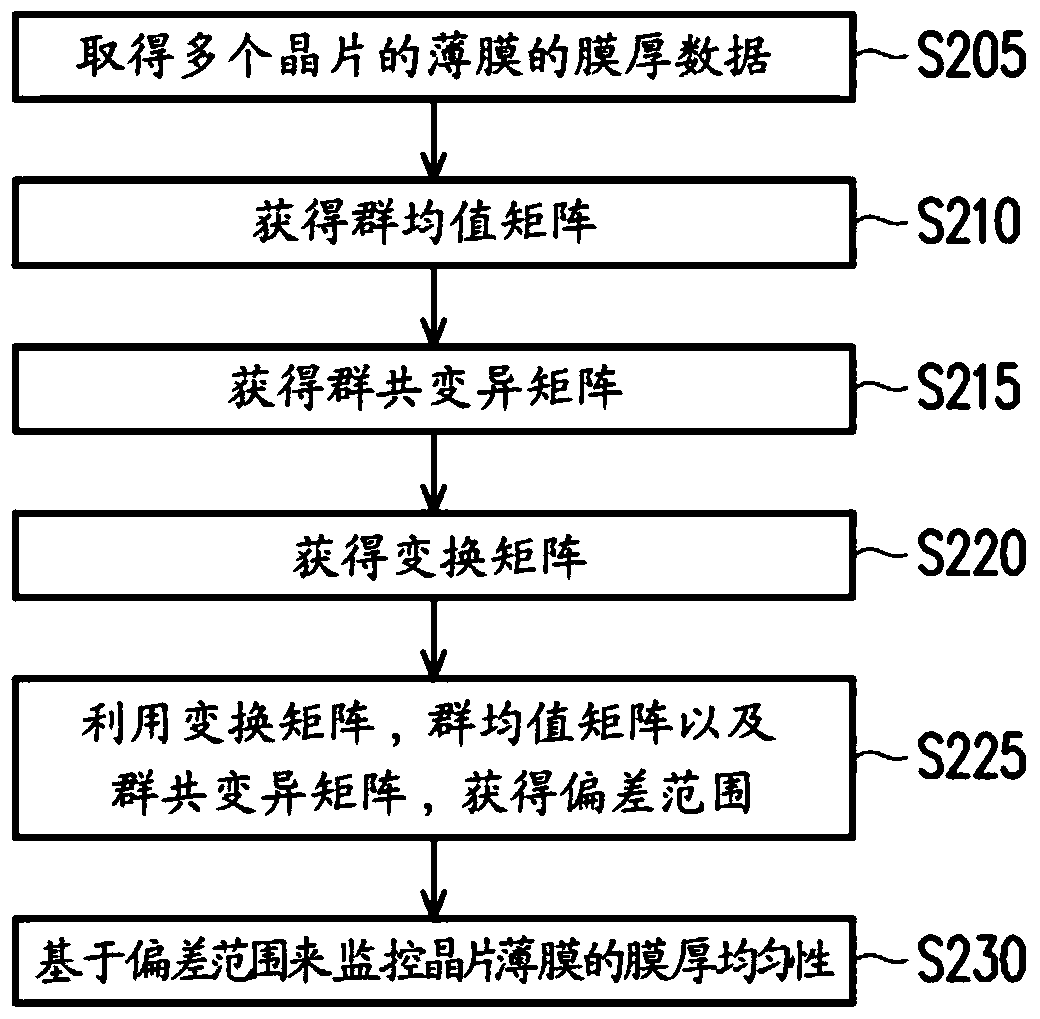

[0042] In the wafer manufacturing process, when the film thickness data and film thickness distribution change, the quality will also start to be abnormal at the same time. Therefore, in order to detect abnormalities early, the present invention proposes a method for automatically monitoring the uniformity of film thickness. The measured data are used to automatically carry out monitoring procedures. In order to make the content of the present invention clearer, the following specific examples are given as examples in which the present invention can actually be implemented.

[0043] figure 1 is a block diagram of a monitoring device for film thickness uniformity according to an embodiment of the present invention. Please refer to figure 1 , the monitoring device 100 includes a processing unit 110 and a storage unit 120 . Here, the processing unit 110 is coupled to the storage unit 120 . The processing unit 110 is, for example, a central processing unit (Central Processing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com