Bismuth sulfide electrode material with specific morphological structure and its application

An electrode material, bismuth sulfide technology, applied in the field of materials, can solve the problems of uneven particle size and agglomeration of bismuth sulfide, and achieve the effect of small impedance and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

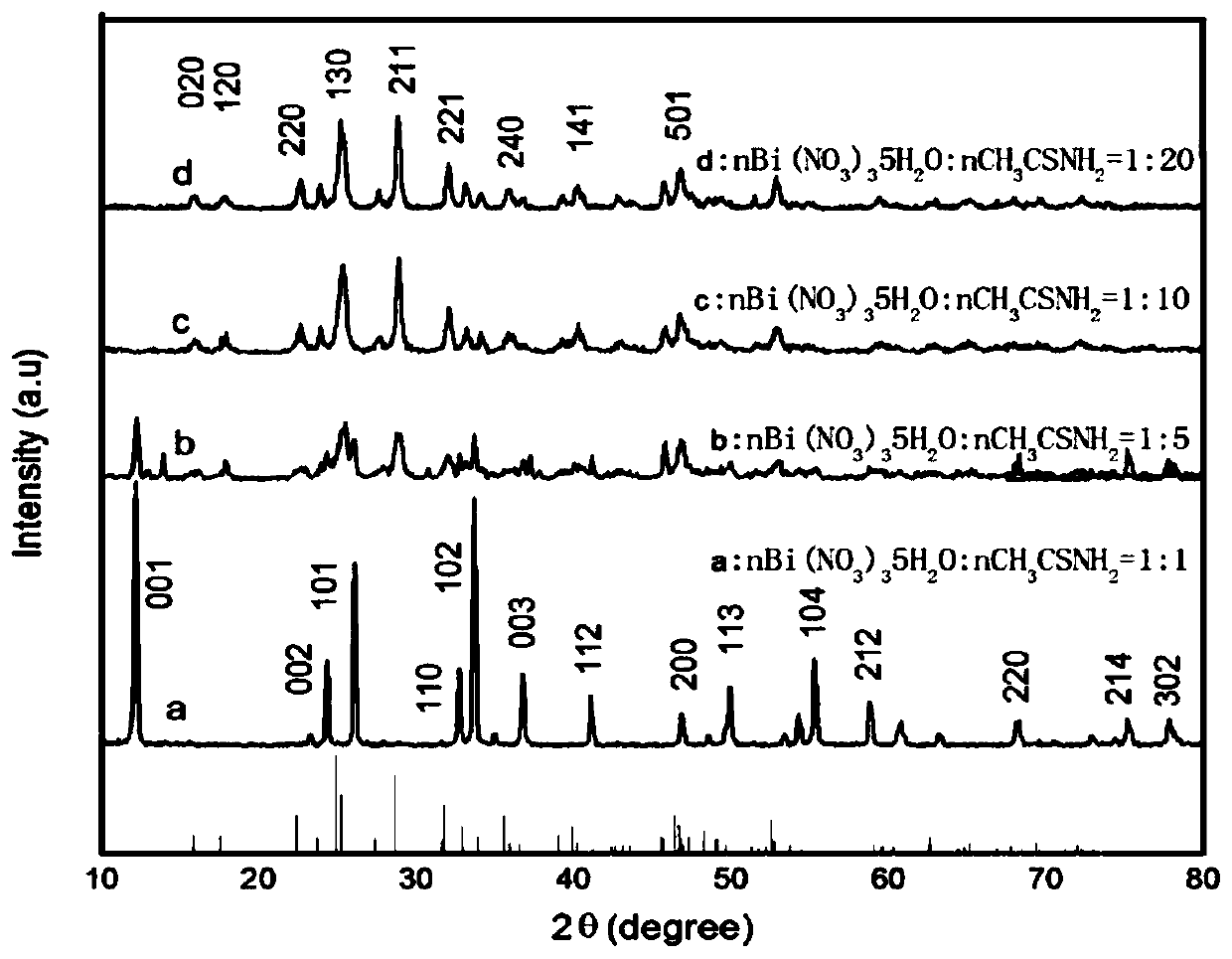

[0034] The preparation method of the bismuth sulfide electrode material with specific morphology of the present invention comprises the following steps:

[0035] a, according to the molar ratio of bismuth and sulfur is 1:1~20, take bismuth nitrate pentahydrate and thioacetamide;

[0036] b. Add deionized water to thioacetamide, and ultrasonically disperse and dissolve for 20-40 minutes to obtain solution A;

[0037] c. Add 3 to 10 mL of hydrochloric acid with a concentration of 0.1 to 5 mol / L into bismuth nitrate pentahydrate, and stir to obtain a transparent and clear solution B;

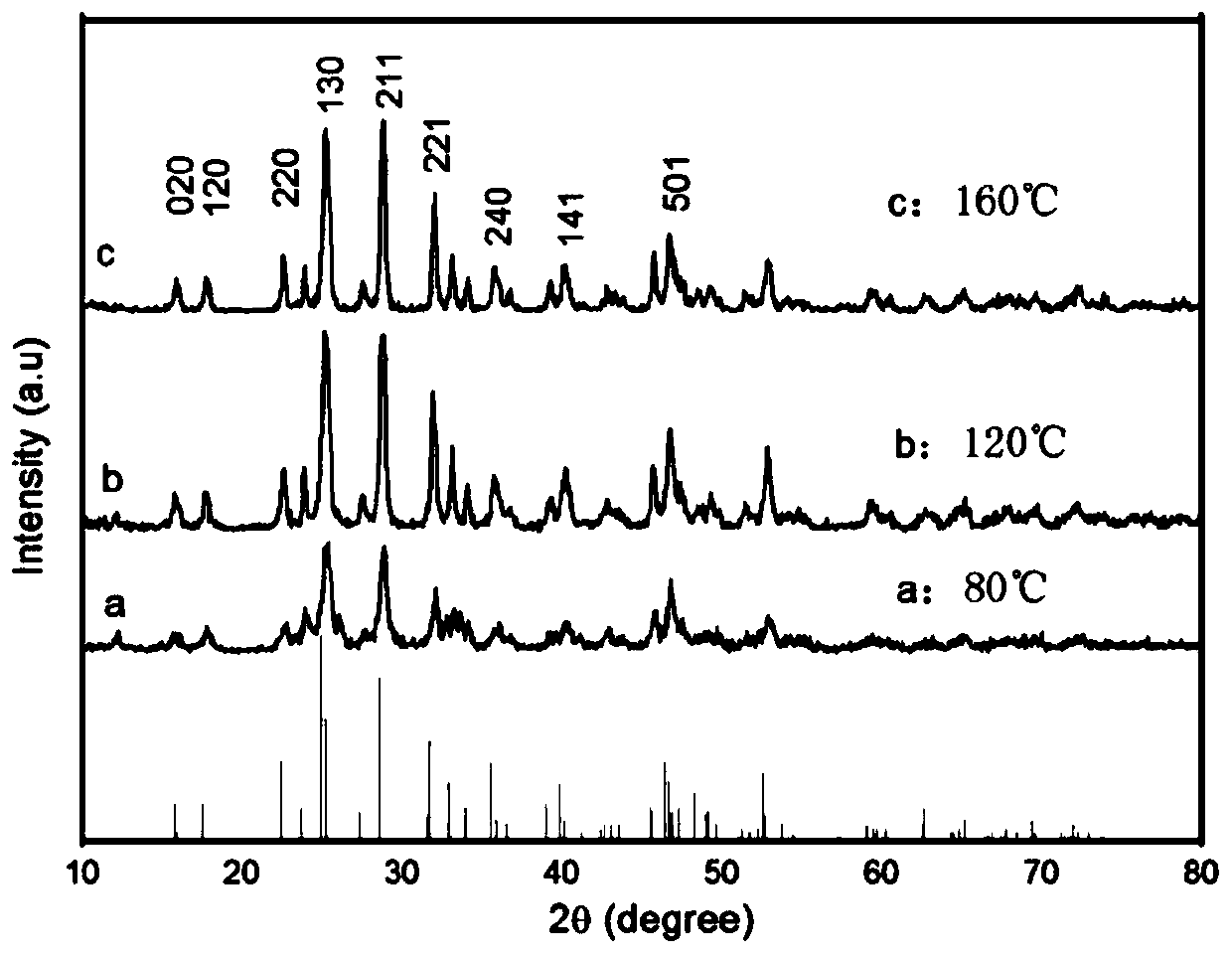

[0038] d. Mix solution A and transparent clear solution B, react at 80-160°C for 1-16 hours, cool to room temperature, wash repeatedly with deionized water and absolute ethanol several times, and centrifuge at a rate of 7000 rpm , the separated product is dried and ground to obtain.

[0039] Further, in the preparation method of the above-mentioned bismuth sulfide electrode material with a specif...

Embodiment 1

[0048] The present embodiment bismuth sulfide electrode material is bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) and thioacetamide (CH 3 CSNH 2 ) is prepared as a precursor by a hydrothermal method, which specifically includes the following steps:

[0049] 1. Weigh Bi(NO 3 ) 3 ·5H 2 O and CH 3 CSNH 2 ;

[0050] Second, the CH 3 CSNH 2 Dissolve in 50mL deionized water, ultrasonically disperse for 30min until uniform, and obtain solution A;

[0051] Three, another Bi(NO 3 ) 3 ·5H 2 Dissolve O in 3-10 mL of hydrochloric acid with a concentration of 0.1-5 mol / L, and stir thoroughly to obtain a transparent and clear solution B;

[0052] 4. Mix the two solutions of A and B in a 100mL hydrothermal reaction kettle, and react at 100°C for 5 hours;

[0053] 5. Wash the cooled reaction product repeatedly with deionized water and absolute ethanol several times, and centrifuge at a rate of 7000 rpm;

[0054] 6. Dry the centrifuged sample in a vacuum oven at 60°C for ...

Embodiment 2

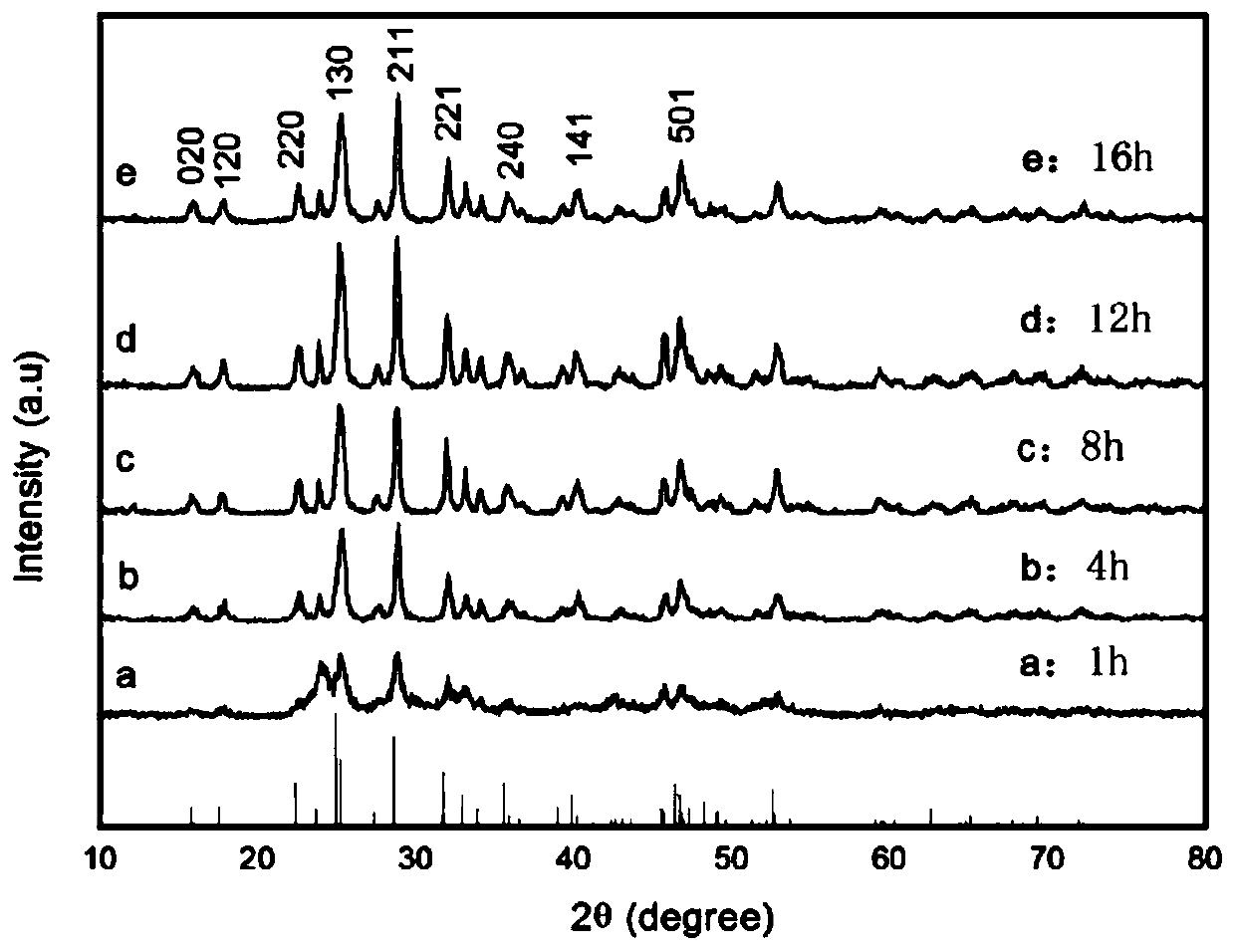

[0059] The present embodiment bismuth sulfide electrode material is bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) and thioacetamide (CH 3 CSNH 2 ) is prepared as a precursor by a hydrothermal method, which specifically includes the following steps:

[0060] 1. According to the molar ratio of bismuth and sulfur is 1:10, weigh 4.8576g Bi(NO 3 ) 3 ·5H 2 O and 0.7533g CH 3 CSNH 2 ;

[0061] Second, the CH 3 CSNH 2 Dissolve in 50mL deionized water, ultrasonically disperse for 30min until uniform, and obtain solution A;

[0062] Three, another Bi(NO 3 ) 3 ·5H 2 O was dissolved in 5 mL of hydrochloric acid with a concentration of 4 mol / L, and stirred thoroughly to obtain a transparent and clear solution B;

[0063] 4. Mix the two solutions of A and B in a 100mL hydrothermal reactor, and react at 100°C for 1h, 4h, 8h, 12h and 16h respectively;

[0064] 5. Wash the cooled reaction product repeatedly with deionized water and absolute ethanol several times, and centr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com