High-voltage shielding structure for power system of electromagnetic separator

A technology of shielding structure and power supply system, applied in the fields of magnetic field/electric field shielding, electrical components, substation/switch layout details, etc., can solve the problem of large size of the power supply cabinet, and achieve the effect of saving the space occupied by the equipment and reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

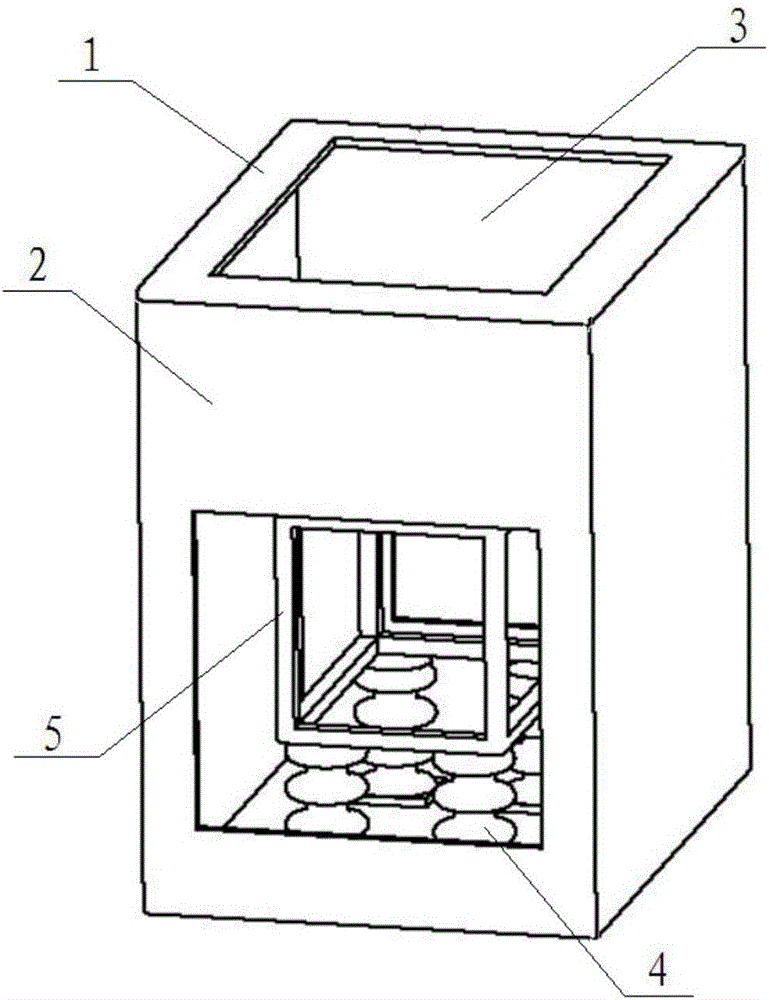

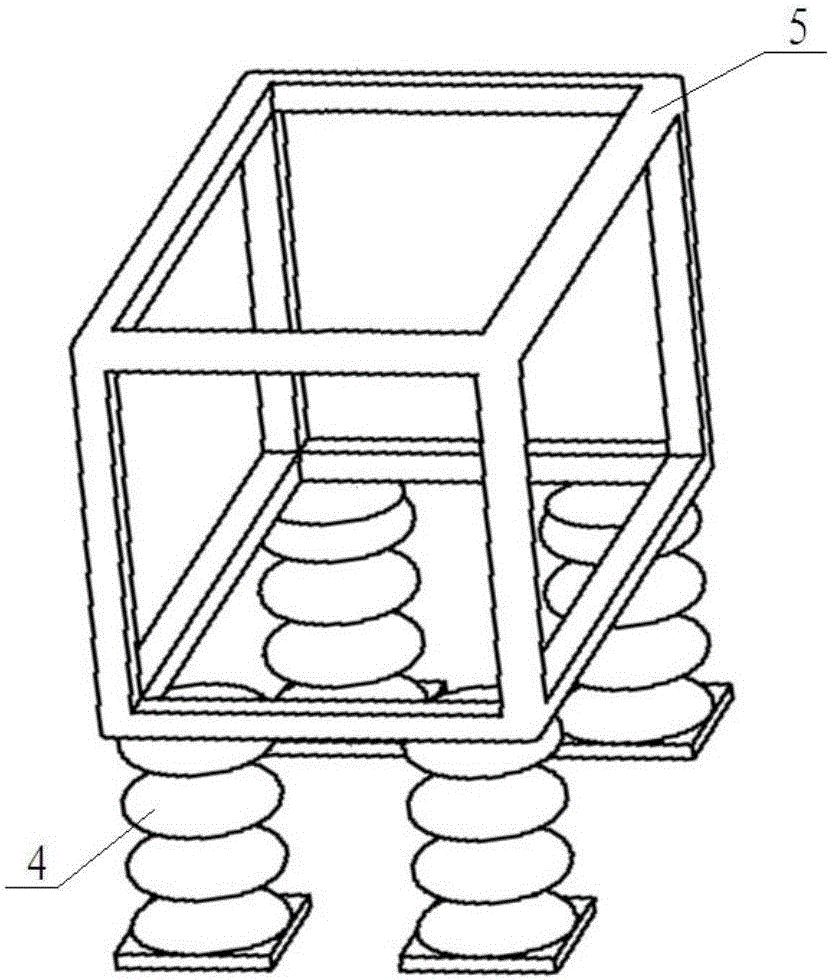

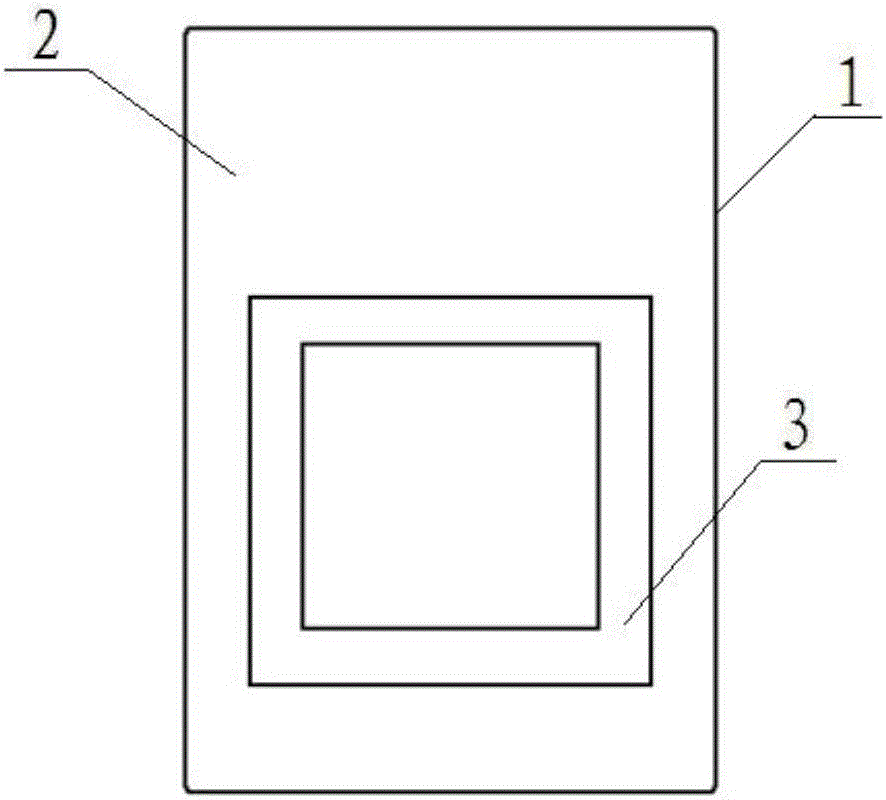

[0022] Such as Figure 1 to Figure 6 As shown, the present invention provides a high-voltage shielding structure for the power supply system of the electromagnetic separator, which is installed in the power supply cabinet of the electromagnetic separator, and is used to shield the high potential part of the power supply system of the electromagnetic separator. The power supply system includes several switching power supply (such as Figure 6 As shown, there are four in this embodiment), the low potential part of the switching power supply includes the mains input end, and the high potential part includes the output end. Among them, the high-potential part and the low-potential part of the switching power supply are isolated by high-voltage primary and secondary windings of a high-frequency transformer, and the (4) high-potential parts of the switching ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com