Composite electric heating tube and preparation method

A technology of electric heating tubes and heating wires, applied in the direction of heating element materials, heating element shapes, etc., can solve the problems that electric heating tubes cannot accurately control the heating temperature, electric heating tubes cannot work normally, and cannot meet actual needs, etc., to achieve Accelerate heat conduction speed, improve heating control accuracy, and reduce the effect of failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

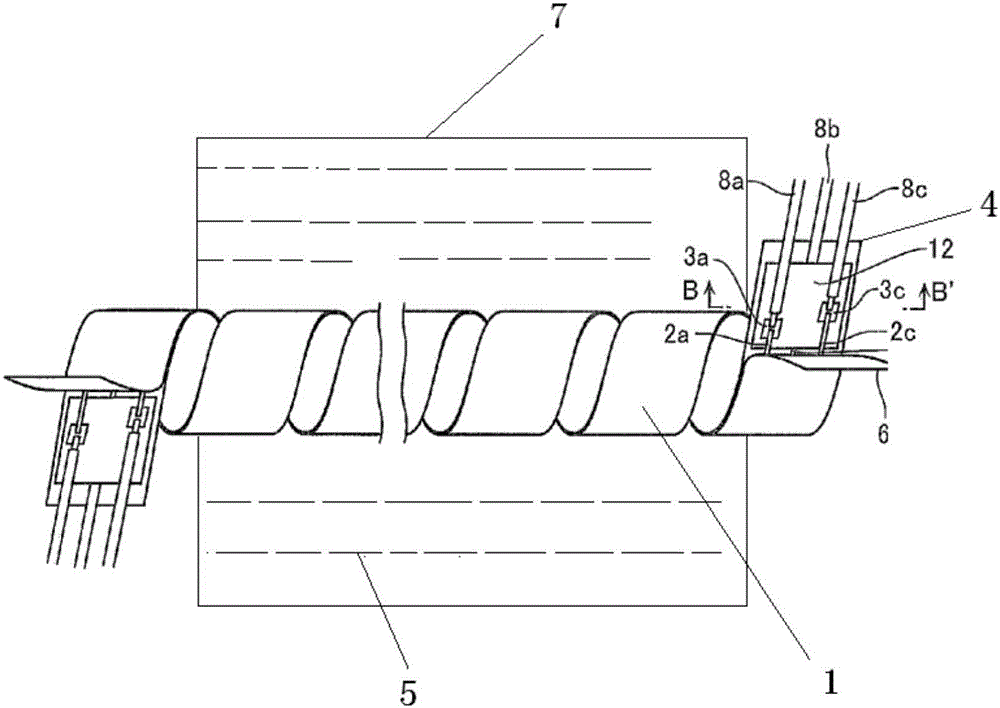

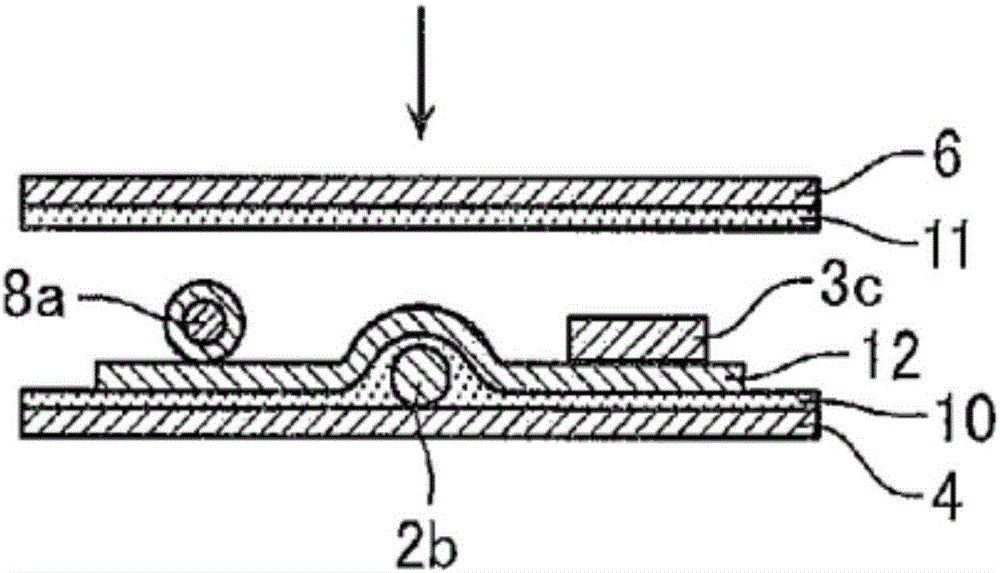

[0027] like figure 1 and figure 2 As shown, the novel composite electric heating tube of the present invention includes a stainless steel empty tube 7, a spiral heating band 1 and a superconducting liquid 5, the spiral heating band 1 is fixedly arranged in the stainless steel empty tube 7, and the spiral heating band 1 The ends of both ends are exposed outside the empty stainless steel tube 7; the superconducting liquid 5 is filled in the empty stainless steel tube 7, and the superconducting liquid 5 is filled with the gap space between the empty stainless steel tube 7 and the spiral heating belt 1; The spiral heating belt 1 includes a first heating wire 2a, a second heating wire 2b, a third heating wire 2c, a first metal foil 4, a second metal foil 6 and an insulating spacer 12, the first metal foil 4 and the second metal foil The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com