Intelligent high-temperature furnace

A high-temperature furnace, intelligent technology, applied in the direction of furnace, furnace lining, electric furnace heating, etc., can solve the problems of inconvenient operation, poor product quality control, inaccurate control, etc., achieve simple structure, improve control accuracy, and improve clinker quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

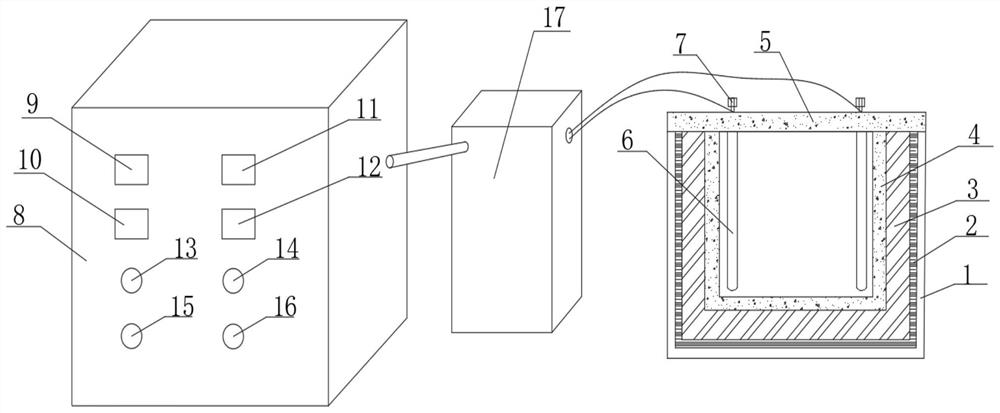

[0022] Such as figure 1 As shown, the intelligent high-temperature furnace of the present invention includes an electric cabinet box 8 connected in sequence, a dedicated transformer 17 for smelting, and a high-temperature furnace device. The high-temperature furnace device includes a high-temperature furnace body and a furnace cover 5, and the high-temperature furnace body includes The shell layer 1 arranged on the outside and the high temperature resistant layer 4 arranged on the inside; a high temperature heating rod 6 extending into the high temperature furnace body is provided at the bottom of the furnace cover 5, and a The terminal 7 connected with the high-temperature heating rod 6; the terminal 7 is connected with the special transformer 17 for smelting, and the special transformer 17 for smelting is connected with the electric cabinet 8. In the intelligent high-temperature furnace of the present invention, through the cooperation of the electric cabinet, special transf...

Embodiment 2

[0024] On the basis of the above embodiments, in order to further better implement the present invention, a second high temperature resistant layer 3 is arranged between the outer shell layer 1 and the high temperature resistant layer 4, and the second high temperature resistant layer 3 A transition layer 2 is arranged between the shell layer 1 and the outer shell layer 1. The setting of the second high temperature resistant layer 3 can achieve further high temperature resistance. Preferably, the high temperature resistant layer 4 and the furnace cover 5 are both made of high temperature mullite bricks. Mullite bricks have a high refractoriness, which can reach above 1790 °C. Load softening start temperature is 1600~1700℃. The compressive strength at room temperature is 70-260MPa. It has good thermal shock resistance and is lightweight.

[0025] Preferably, the second high-temperature-resistant layer 3 is made of high-alumina bricks. The high-alumina bricks contain more Al...

Embodiment 3

[0028] On the basis of the above embodiments, in order to further and better implement the present invention, the outer shell layer 1 is made of steel plate, and the steel plate generally can be 304 stainless steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com