High-speed chip mounting head

A patch head, high-speed technology, applied in the direction of electrical components, printed circuit manufacturing, printed circuit, etc., can solve the problems of expensive equipment, complicated manufacturing process, high manufacturing cost, etc., and achieve the effect of eliminating restlessness, reducing volume and reducing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

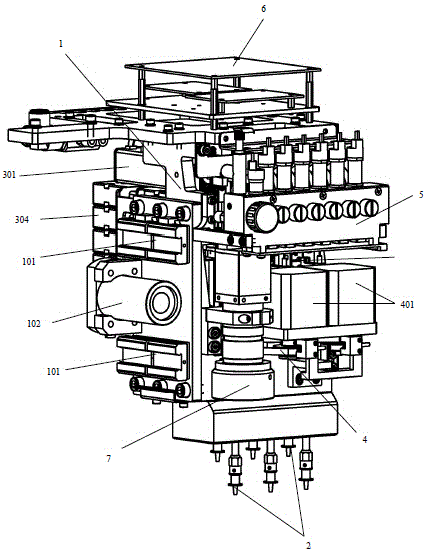

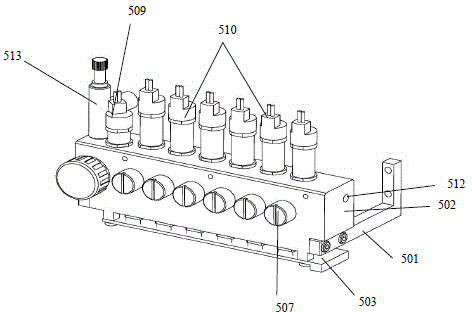

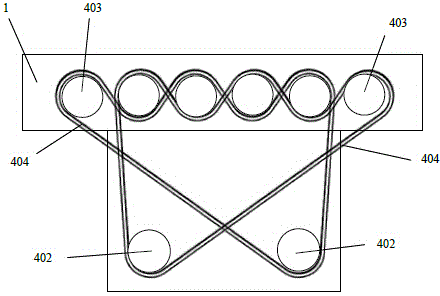

[0024] Such as figure 1 - Figure 5 As shown, a high-speed placement head includes a placement head bracket 1, a plurality of placement shafts 2 installed in the placement head bracket 1, a Z-direction lifting mechanism 3 that drives the placement shaft 2 to rise and fall, and a drive placement The R-direction angle mechanism 4 that the shaft 2 rotates in a circle, the vacuum module 5 that adjusts the suction and retrieving action of the patch shaft 2, the integrated control component 6 is installed on the upper back of the placement head bracket 1, and the upper front of the placement head bracket 1 is installed There is a vacuum module 5, the front of the middle part of the placement head bracket 1 is installed with an R-direction stepping motor 401 driving the R-direction corner mechanism 4 and a CCD camera 7 for collecting images, and the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com