Production device of strong-tension rice noodles

A production device and pulling force technology, which is applied in the field of rice noodle production devices, achieves the effects of reducing labor intensity, short rehydration time, and feasible production process

Inactive Publication Date: 2017-01-11

广西马中粮油有限公司

View PDF8 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0009] The rice flour processing method of above-mentioned open document report has nothing in common with each other, but all is to set about aspects such as improving toughness, prolong

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

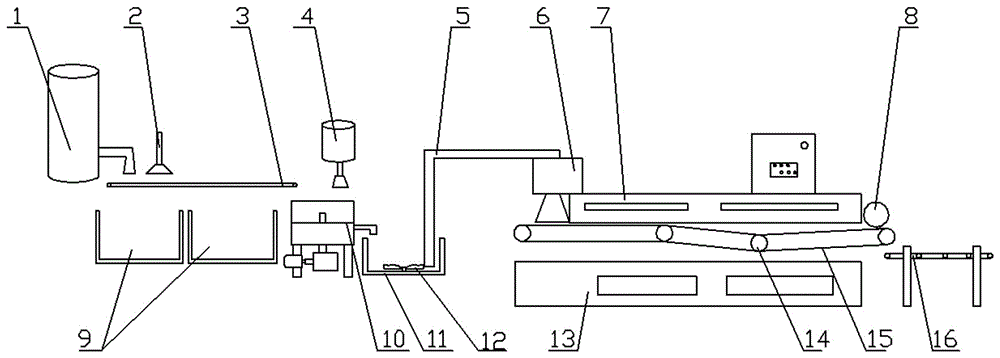

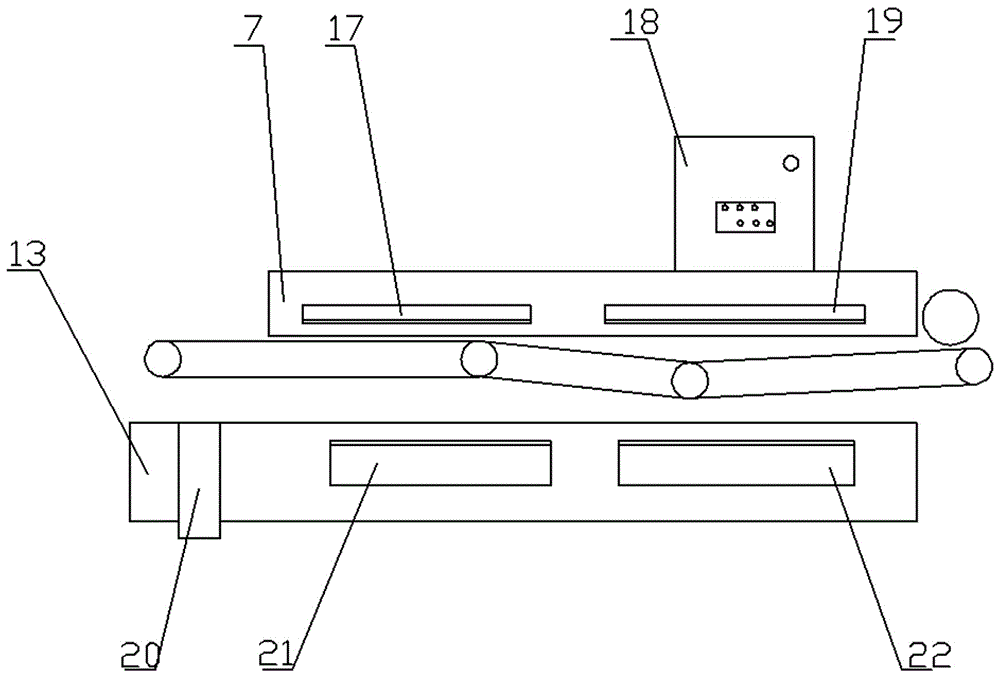

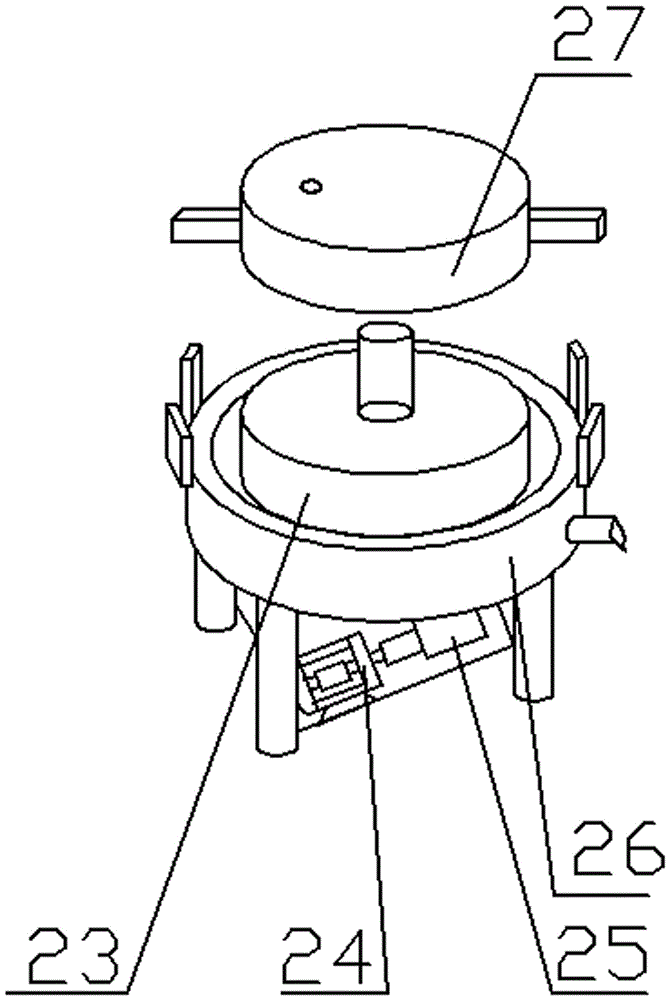

The invention discloses a production device of strong-tension rice noodles. The production device of the strong-tension rice noodles comprises a rice soaking device, a rice washing device, a raw material conveying device, a stone mill millstone, a pulp preparing machine, a pulp conveying pump, a steam chamber, a cutter and a finished product conveying device according to the forming process, wherein a discharge opening of the rice soaking device is arranged at the feeding end of the raw material conveying device; the rice washing device is arranged on the front part of the discharge opening of the rice soaking device; the discharge end of the raw material conveying device is connected with a feeding opening of the stone mill millstone; the feeding opening of the stone mill millstone is also connected with a dispenser; a discharge opening of the stone mill millstone is connected with the pulp preparing machine; a stirrer is arranged in the pulp preparing machine; the pulp preparing machine is connected with the pulp conveying pump through a conveying pipe; the outlet of the pulp conveying pump is connected with the inlet of the steam chamber; the outlet of the steam chamber is connected with the finished product conveying device; the cutter used for cutting the rice noodles is arranged above the outlet of the steam chamber. The strong-tension rice noodles with a good curing effect, high transparency and smooth surface can be produced by a production line of the invention, the cost is lower and the energy consumption is less.

Description

technical field [0001] The invention relates to the technical field of food processing equipment, in particular to a production device for rice flour processed from rice. Background technique [0002] Rice noodles refer to strip-shaped and silky rice products made from rice as raw material through processes such as soaking, cooking, and layering, rather than powdery materials that are made from rice as raw material and ground in the sense of the word. The texture of rice noodles is flexible and delicate, and it is served with various dishes or soup ingredients for soup or dry frying. It is smooth and tasty, and is deeply loved by consumers (especially those in the south). There are many varieties of rice noodles. According to the processing type, there are round noodles (extruded rice noodles) and flat noodles (cut noodles). According to packaging, there are row rice noodles, square rice noodles, corrugated rice noodles, and silver rice noodles; wait. Their production proc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A23L7/10A23P30/00

Inventor 何青白伟锋

Owner 广西马中粮油有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com