A material-saving stamping die and its coiling device

A stamping die and coil material technology, which is applied in the field of material-saving stamping die and its coil device, can solve the problems of low material utilization rate of stamping parts, one more process, and increased cost, so as to improve utilization rate, reduce cost, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

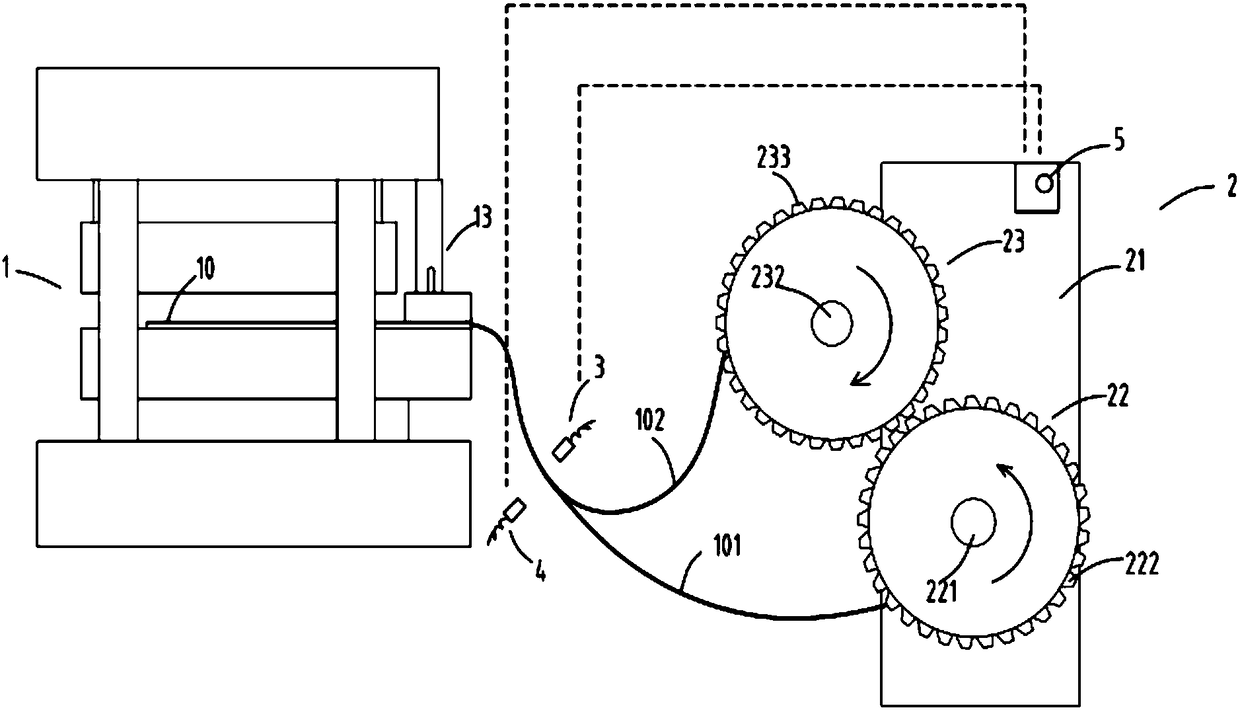

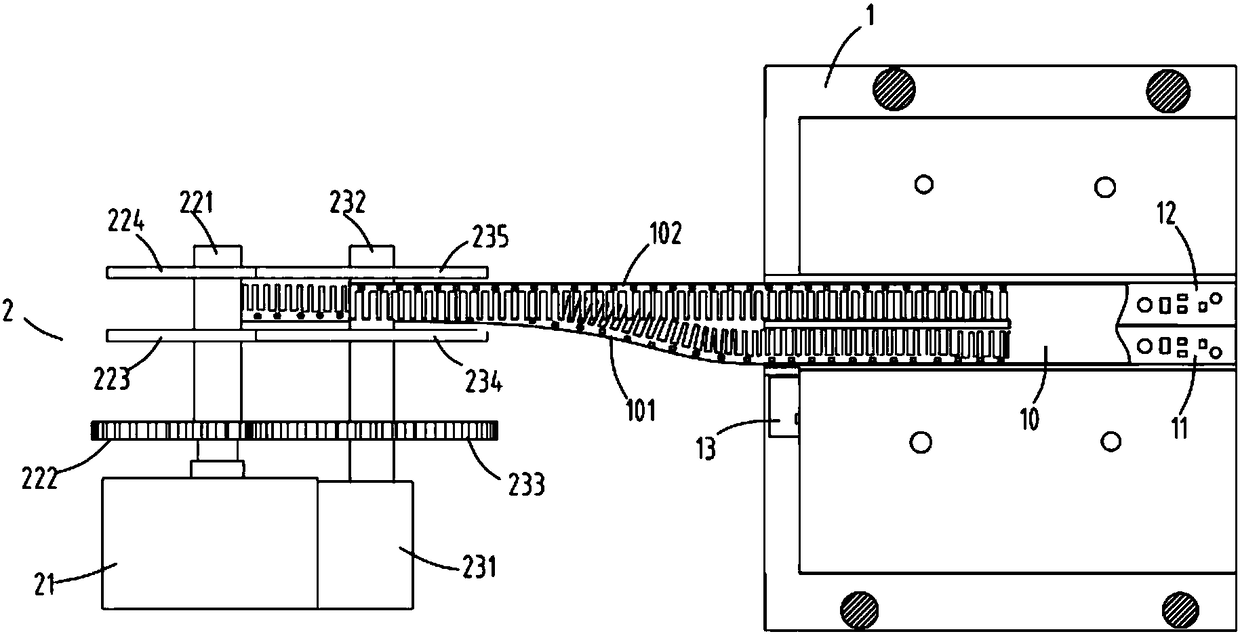

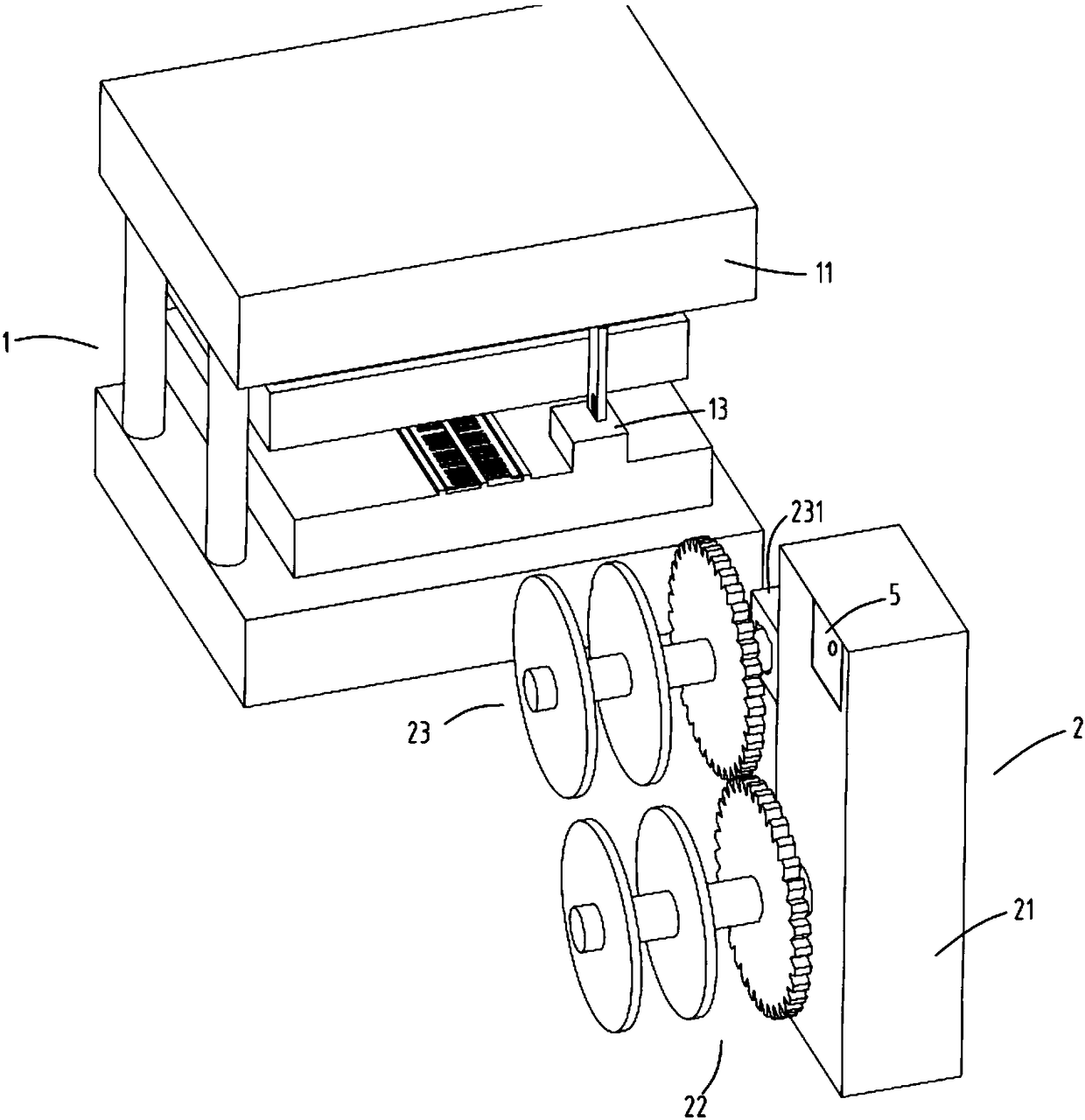

[0030] figure 1 It is a schematic diagram of the front view of the material-saving stamping die and its coiling device, figure 2 It is a top view schematic diagram of the material-saving stamping die and its coiling device, image 3 It is a partial three-dimensional schematic diagram of the material-saving stamping die and its coiling device, Figure 4 It is a schematic diagram of the drawing device of the material-saving stamping die and its coiling device, Figure 5 It is a schematic diagram of the transmission block and hooking part of the pulling device, Image 6 It is the internal schematic diagram of the hooking part of the pulling device, Figure 7 It is the base, guide seat and mounting seat of the pulling device. Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7As shown, what is provided in this embodiment is a material-saving stamping die and its coiling device, including a stamping die part 1 and a coiling part 2; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com