Automatic feeding and discharging equipment for swelling pressure forming of automobile axle housing pipe fittings

An automatic loading and unloading and axle housing technology, which is applied in the direction of pushing out equipment, vehicle parts, metal processing equipment, etc., can solve the problems of poor positioning accuracy of pipe fittings, unclean pipe liquid dumping, and low efficiency of manual loading and unloading, so as to improve production Efficiency, simple structure and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

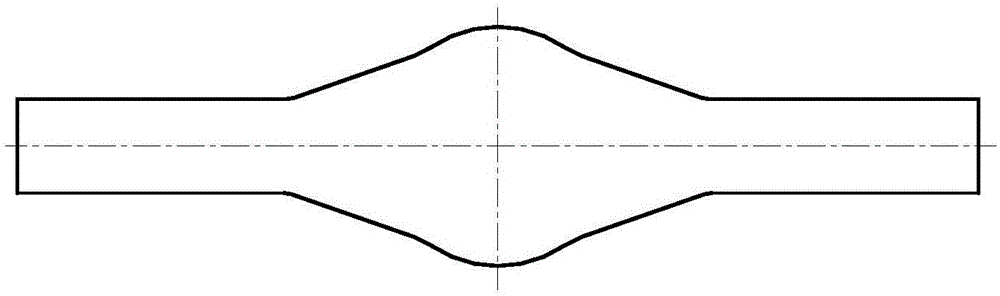

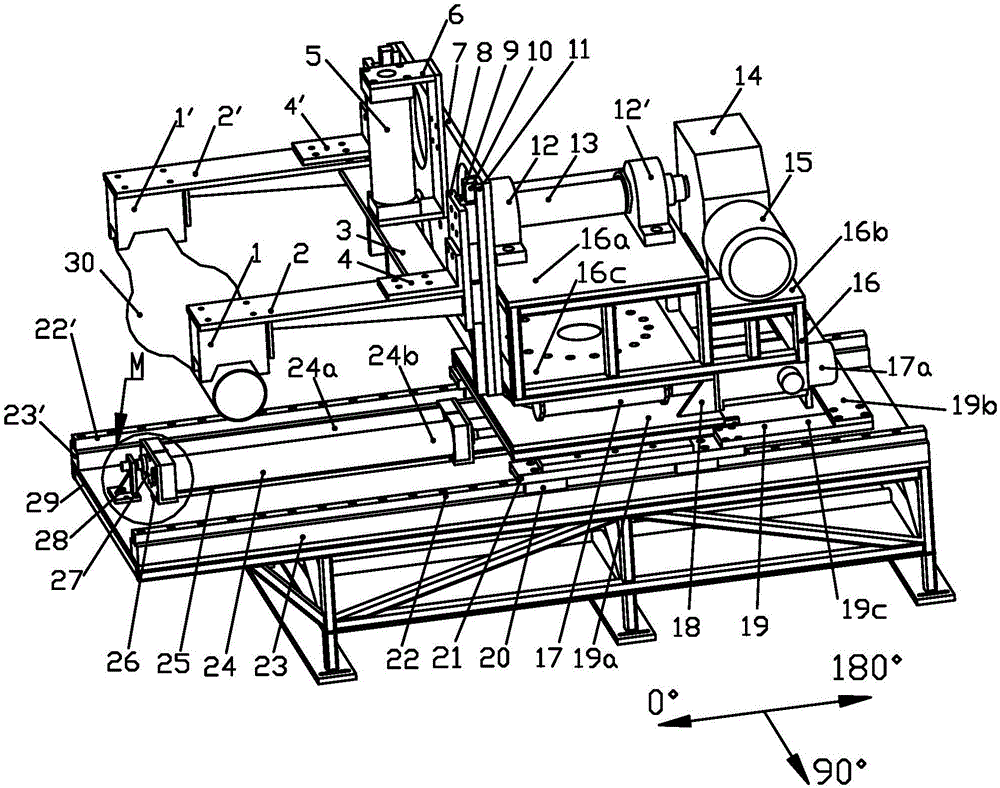

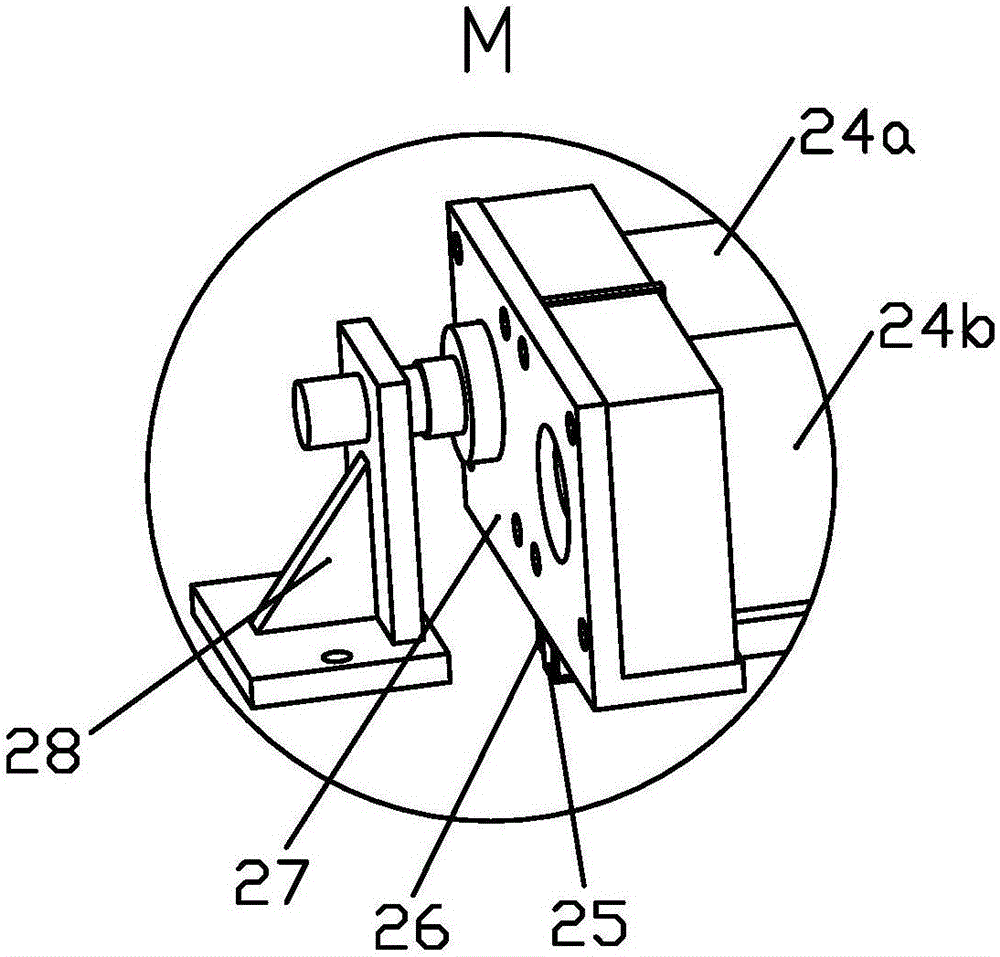

[0030] figure 2 The invention discloses an automatic loading and unloading equipment for automobile axle housing pipe fittings formed by expansion and compression, which includes a grabbing device, a lifting device, a vertical rotating device, a horizontal rotating device and a longitudinal moving device. The grabbing device includes V-shaped electromagnetic blocks I, II (1, 1'), straight arms I, II (2, 2'), beam 3, and L-shaped connecting plates I, II (4, 4'). The crossbeam 3 and the straight arms I and II (2, 2') installed on the left and right sides of the crossbeam 3 form a semi-enclosed frame, and V-shaped electromagnetic blocks I and II are installed under the front ends of the straight arms I and II (2, 2'). Ⅱ (1, 1′), through the energization and de-energization of the V-shaped electromagnetic block Ⅰ, Ⅱ (1, 1′), the grasping and placing of the pipe fittings are realized; the rear of the straight arm Ⅰ, Ⅱ (2, 2′) The top of the end is fixedly connected with the verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com