Bench-type stirring and friction welding equipment

A technology of friction stir and welding equipment, which is applied in the field of machinery, can solve the problems of not being able to use dual motors and reduce welding speed, etc., and achieve the effect of improving welding efficiency, increasing welding speed and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, achievement goals and effects realized by the present invention easy to understand, the present invention will be further described below with reference to the specific embodiments.

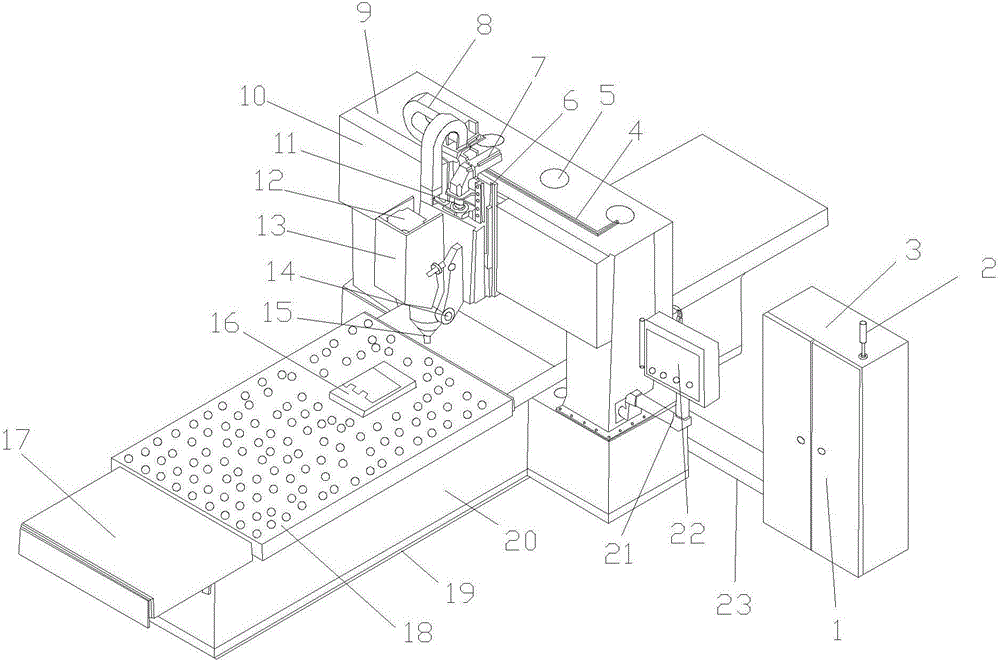

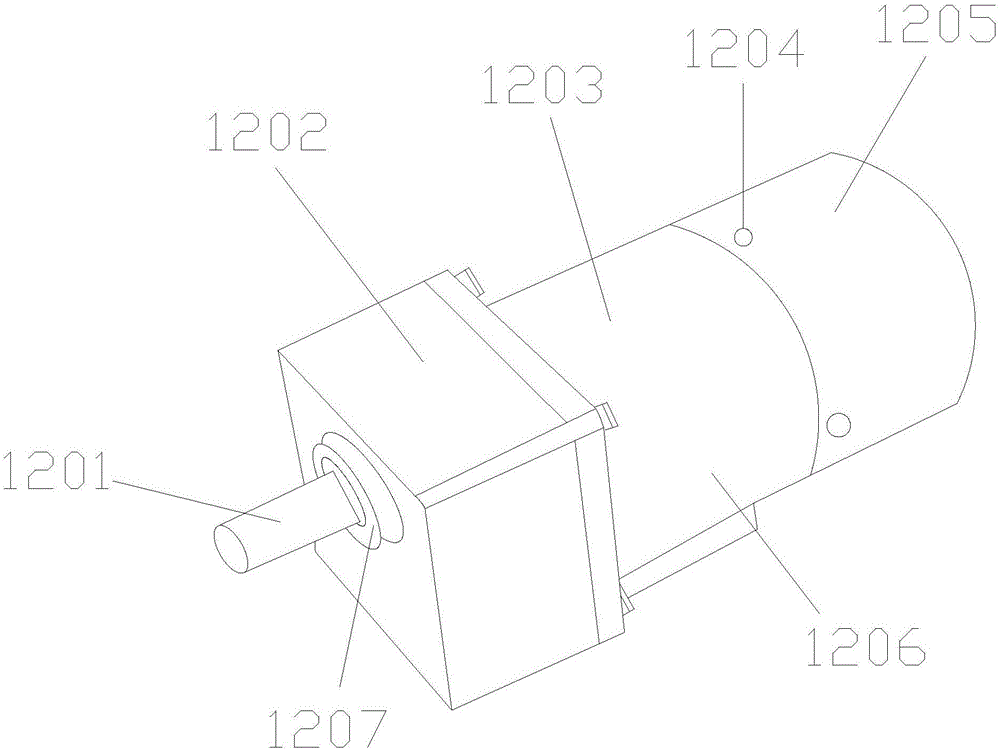

[0016] see Figure 1-Figure 2 , The present invention provides a technical solution: a desktop friction stir welding equipment, its structure includes: a box door 1, a warning light 2, a control box 3, an electric wire 4, an air diffuser 5, a connecting plate 6, an adjuster 7, a U-shaped 8, the main body 9, the anti-collision plate 10, the bearing 11, the double motor device 12, the fixed frame 13, the movable shaft 14, the stirring needle 15, the fixed plate 16, the telescopic table 17, the suction bed 18, the bottom plate 19, the bed 20, Conduit 21, switch box 22, wire box 23, the box door 1 is set on the control box 3, the warning light 2 is connected with the control box 3, the wire 4 is set on the main body 9, the air diffuser 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com