A pole cleaning robot adaptable to different diameters

A cleaning robot, adapting to different technologies, applied in the field of robots, can solve the problems of high labor cost, high labor intensity, poor adaptability, etc., achieve the effect of repeated cleaning and meet diverse needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment, but they are not limitation of the present invention:

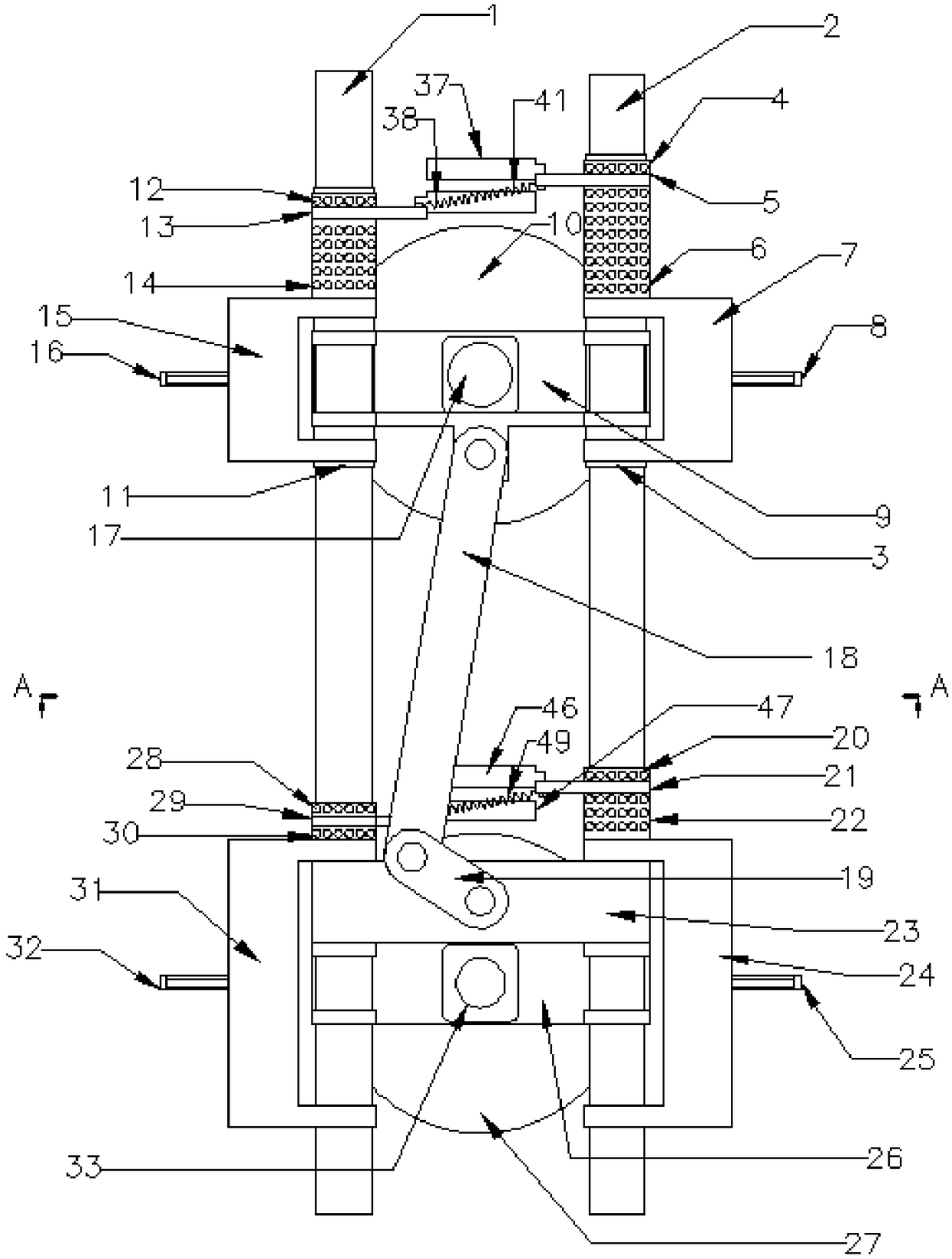

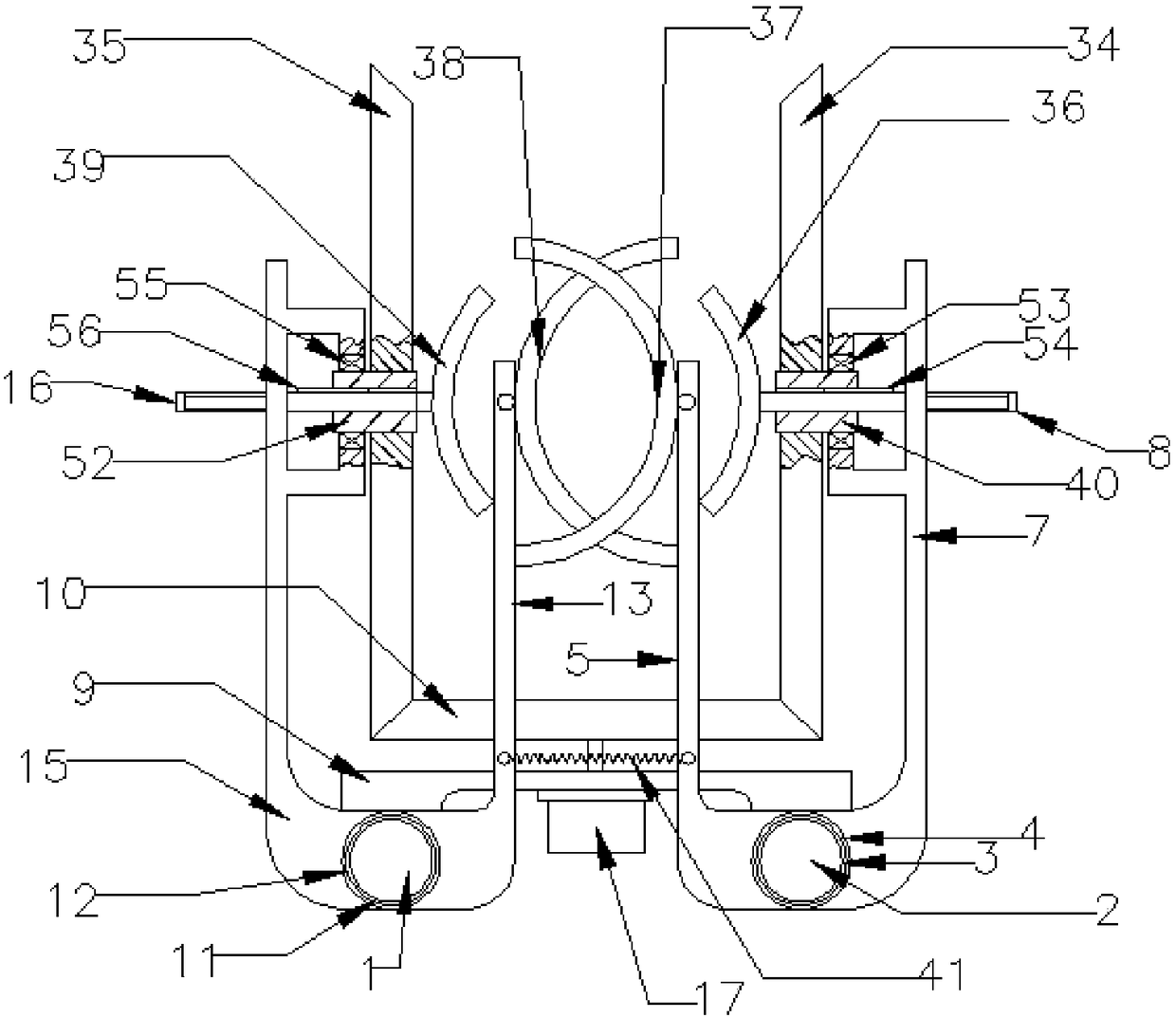

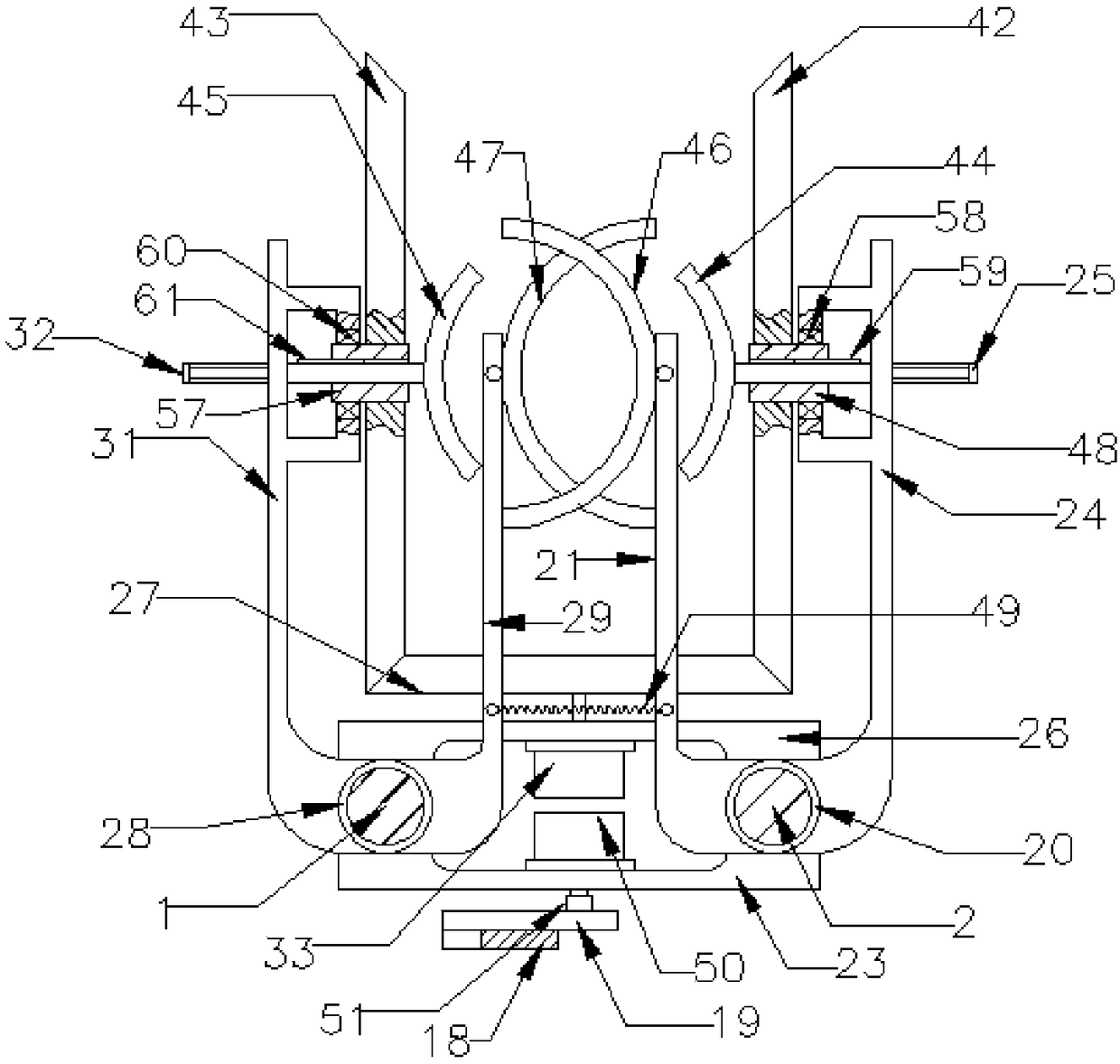

[0037] Such as figure 1 , figure 2 with image 3 As shown, the climbing pole cleaning robot adapted to different diameters includes the first guide rod 2, the second guide rod 1, the first sleeve 3, the second sleeve 11, the first positioning sleeve 4, and the second positioning sleeve 6 , the third positioning sleeve 12, the fourth positioning sleeve 14, the first cleaning brush bracket 5, the second cleaning brush bracket 13, the first driven bevel gear bracket 7, the second driven bevel gear bracket 15, the first transmission Lead screw 8, second transmission screw 16, upper manipulator driving bevel gear 10, upper manipulator control motor support 9, first gear shaft 40, second gear shaft 52, connecting rod 18, crank 19, fifth positioning sleeve 20 , the sixth positioning sleeve 22, the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com