Passenger side air bag restraint system reinforcing frame

A side airbag and reinforcement frame technology, which is applied in the passenger side airbag reinforcement frame field, can solve the problems of high cost, large mold modification, passenger injury, etc., and achieve the effects of flexible strength adjustment, improved transmission capacity, and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

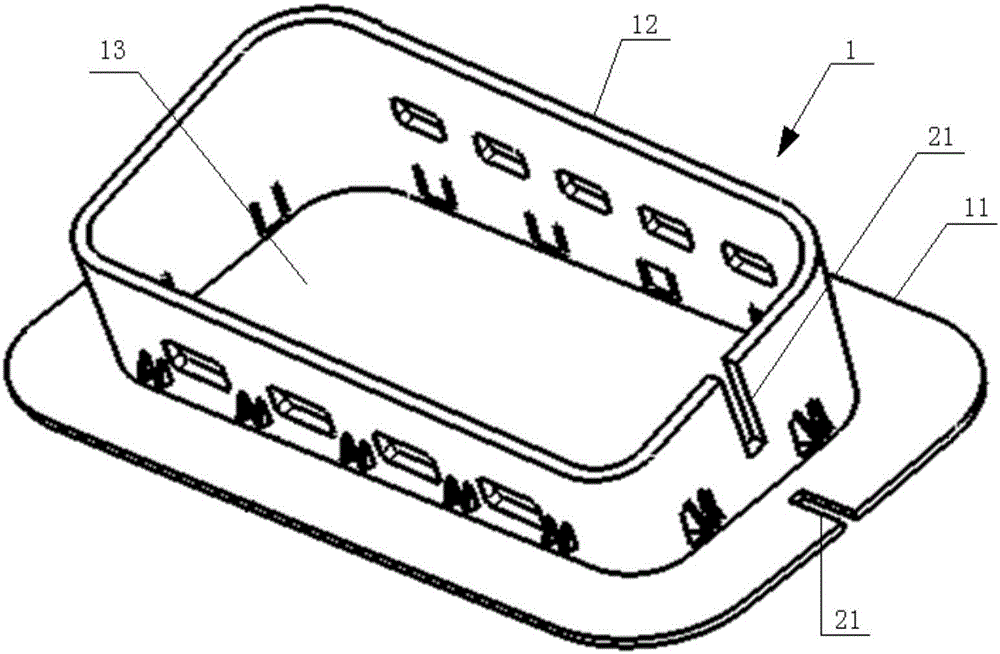

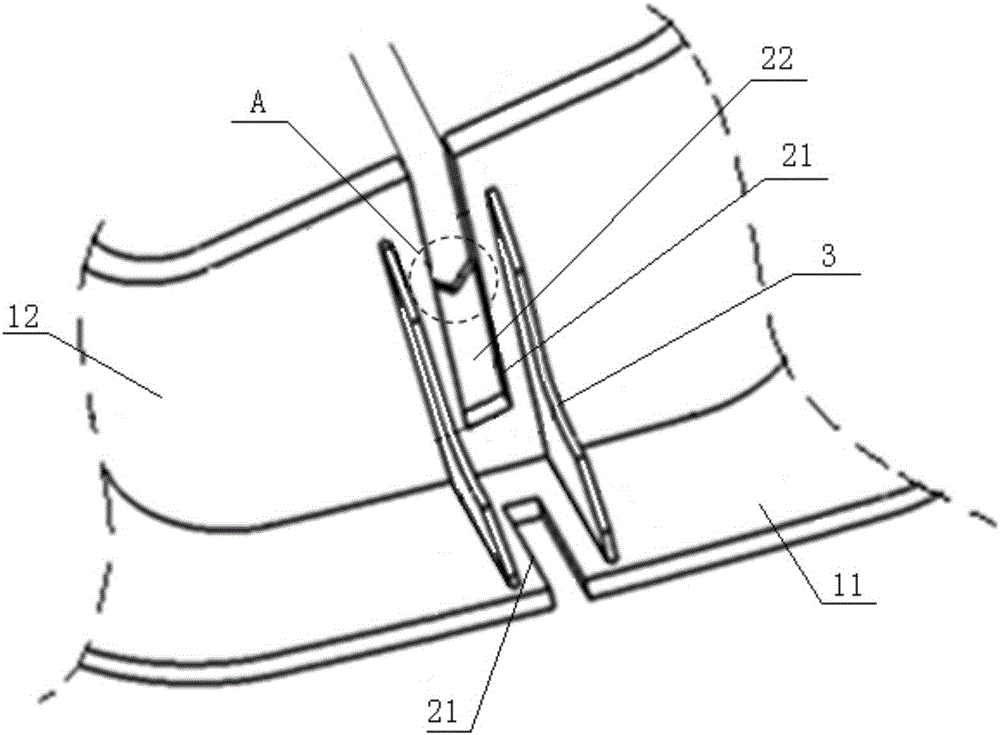

[0027] According to the attached Figure 2-9 , give a preferred embodiment of the present invention, and give a detailed description, so that the functions and characteristics of the present invention can be better understood.

[0028] see figure 2 , a passenger side airbag reinforcement frame 1 according to Embodiment 1 of the present invention includes an airbag reinforcement frame body, two strength weakening structures are arranged on the airbag reinforcement frame body, and the number of strength weakening structures can be determined according to other embodiments. Adjustment is required. As long as the structural space of the airbag reinforcement frame 1 on the passenger side allows, the strength weakening structure can be applied to any position of the side wall edge and the substrate edge of the airbag reinforcement frame 1 .

[0029] Such as figure 2 As shown, wherein the airbag reinforcement frame body includes a base plate 11 and a side frame body 12 extending...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com