An automatic rotary feeding and feeding device for glass tube fusing and cutting

An automatic rotation and feeding device technology, applied in glass cutting devices, glass production, glass manufacturing equipment, etc., can solve the problems affecting the health of operators, low production efficiency, and harsh working environment, etc., to improve fusing efficiency and simple structure , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below.

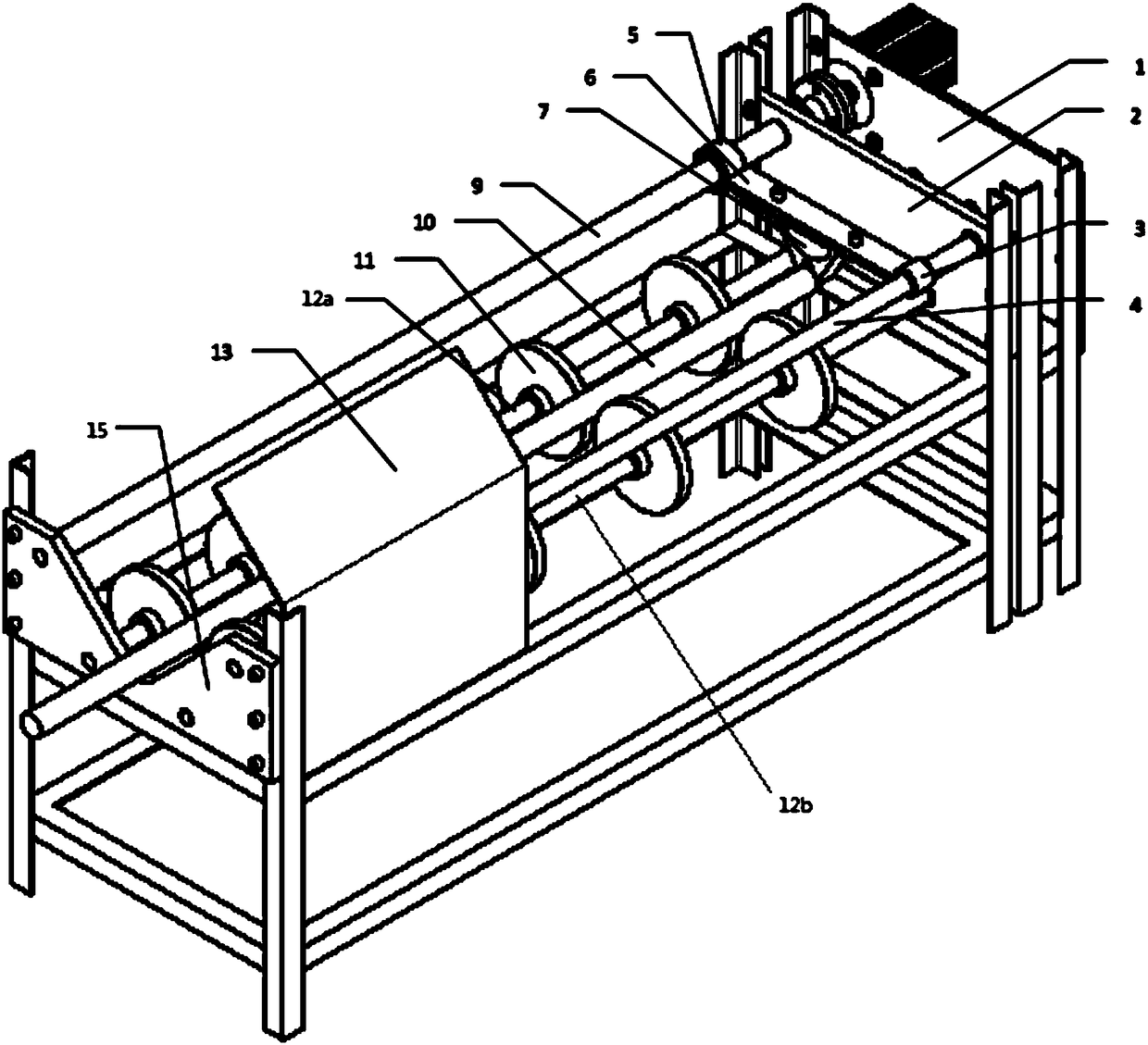

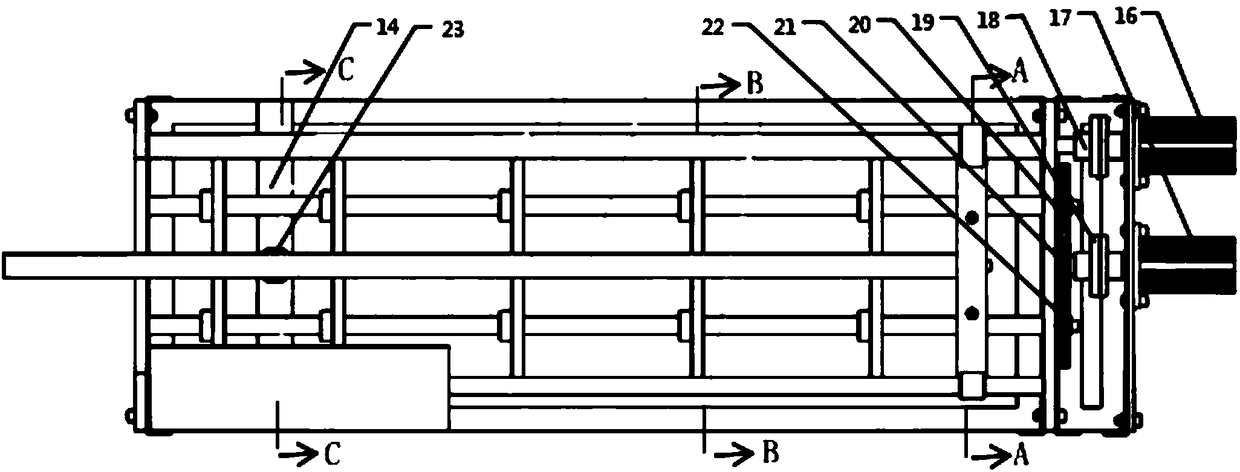

[0041] An automatic rotary feeding and feeding device for fusing and cutting glass tubes, comprising: a floating clamping mechanism, an automatic feeding mechanism, a rotating mechanism, a feeding driving mechanism, a rotating driving mechanism, a frame, a protective mechanism, and a gas lamp.

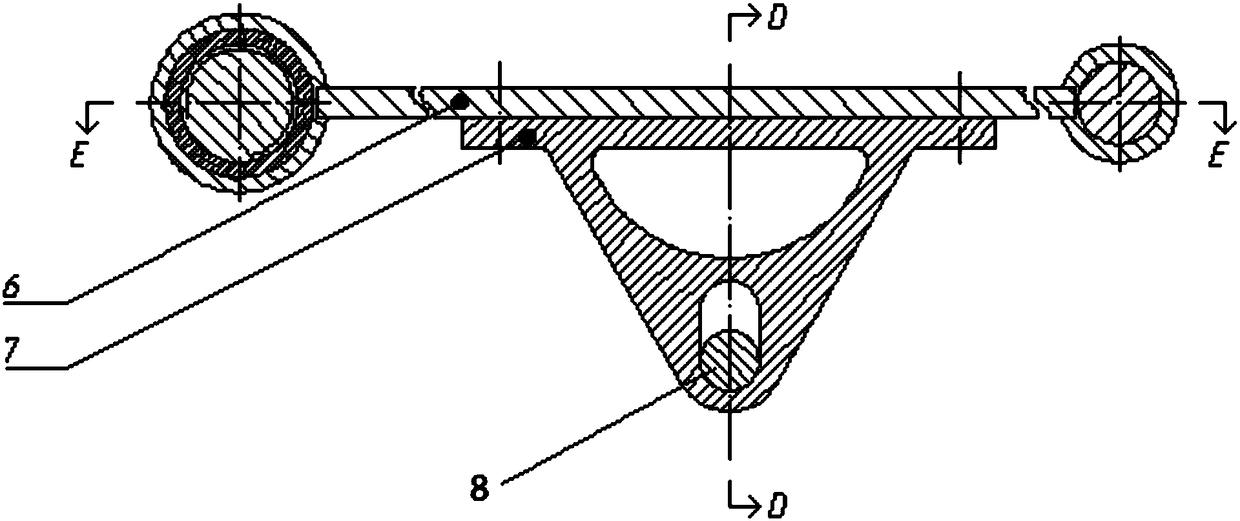

[0042] The floating clamping mechanism includes a mandrel, a connecting rod, a support frame, and a clamping mechanism, wherein the clamping mechanism includes two bayonet pins, a bayonet spring, and two bayonet nuts. The support frame is installed on the connecting rod, and then it moves forward. The mandrel is floatingly installed in the bar-shaped hole in the middle and lower part of the support frame through fastening screws and retaining rings, and different types of mandrels can be replaced, which is convenient for clamping glass tubes of different diameters. The glass tube is clamped on the mandrel, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com