Cement grinding aid and preparation method thereof

A cement grinding aid and grinding aid technology, applied in the field of cement additives and their preparation, can solve the problems of affecting the performance of grinding aid enhancement, excessive chloride ion content, excessive alkali content, etc., to reduce energy efficiency, increase production, improve The effect of cement properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

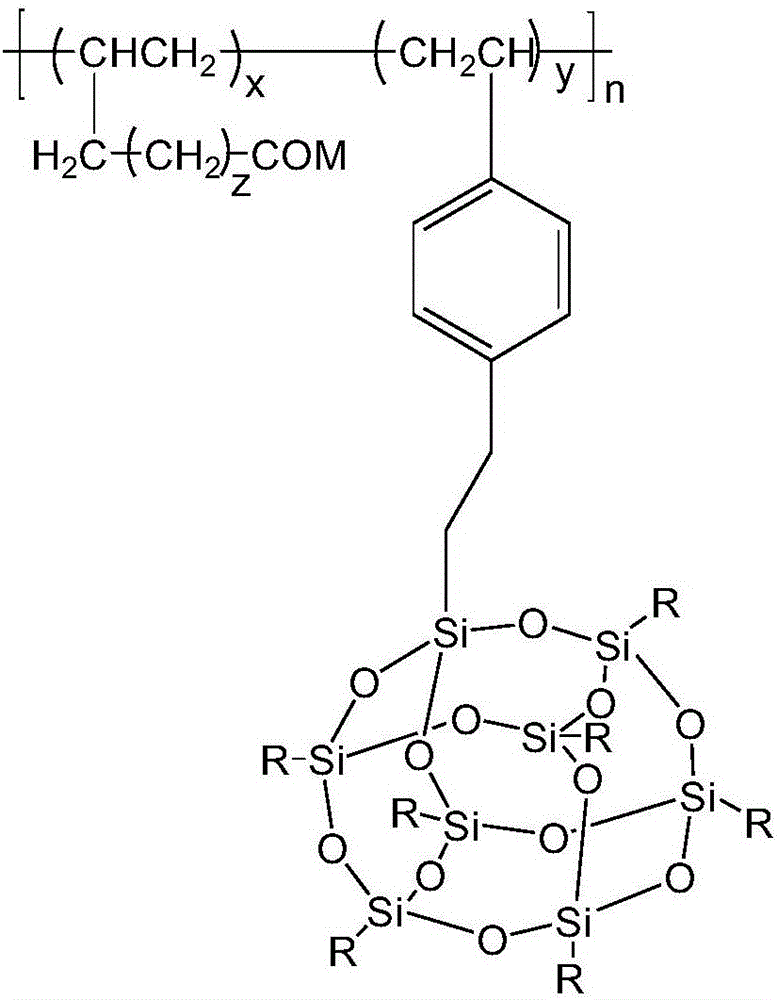

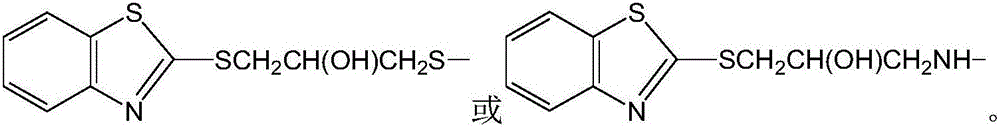

Method used

Image

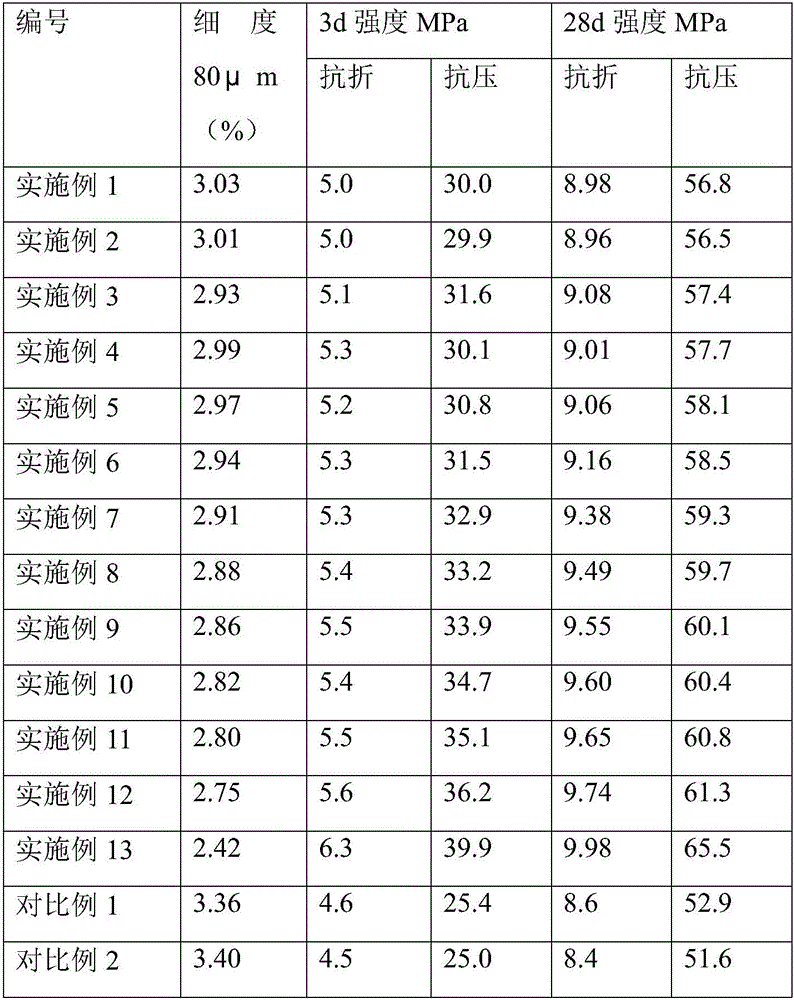

Examples

Embodiment approach

[0023] As a preferred embodiment of the present invention, the grinding aid includes the following components in weight percent: 10-15% alcohol amine compounds, 2-4% molasses, 1-3% sodium sulfate, 5-10% chloride Sodium, 10-15% sodium thiocyanate, 50-55% water.

[0024] As a preferred embodiment of the present invention, the grinding aid includes the following components in weight percent: 10-13% alcohol amine compounds, 2-3.5% molasses, 1-2% sodium sulfate, 7-10% chloride Sodium, 10-15% sodium thiocyanate, 52-55% water.

[0025] As a preferred embodiment of the present invention, the grinding aid comprises the following components in weight percent: 12% alcohol amine compound, 3.1% molasses, 1% sodium sulfate, 10% sodium chloride, 15% sodium thiocyanate , 53.5% water.

[0026] As a preferred embodiment of the present invention, the alcohol amine compound is one or more of diethanolamine, triethanolamine, diethanol monoisopropanolamine, and diisopropylethanolamine. The dieth...

Embodiment approach 1

[0044] Embodiment 1, a cement grinding aid, the grinding aid comprises the following components in weight percentage: 10-20% alcohol amine compound, 1-5% molasses, 0.5-3% sodium sulfate, 5-15% chlorine Sodium chloride, 10-20% sodium thiocyanate, 50-60% water.

Embodiment approach 2

[0045] Embodiment 2 is the same as Embodiment 1, except that the grinding aid includes the following components in weight percent: 10-15% alcohol amine compounds, 2-4% molasses, 1-3% sodium sulfate, 5% - 10% sodium chloride, 10-15% sodium thiocyanate, 50-55% water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com