A kind of polymer type heavy oil demulsifier and preparation method thereof

A technology of demulsifier and polymer, which is applied in the field of polymer-type viscous oil demulsifier and its preparation, can solve the problems of high demulsification temperature of demulsifier, large amount of demulsifier, long dehydration time, etc., and achieve fast demulsification speed, Strong demulsification ability and low demulsification temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

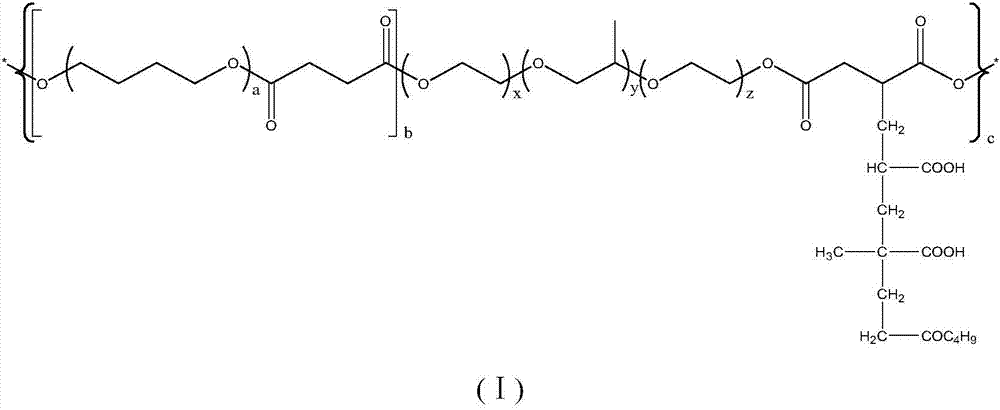

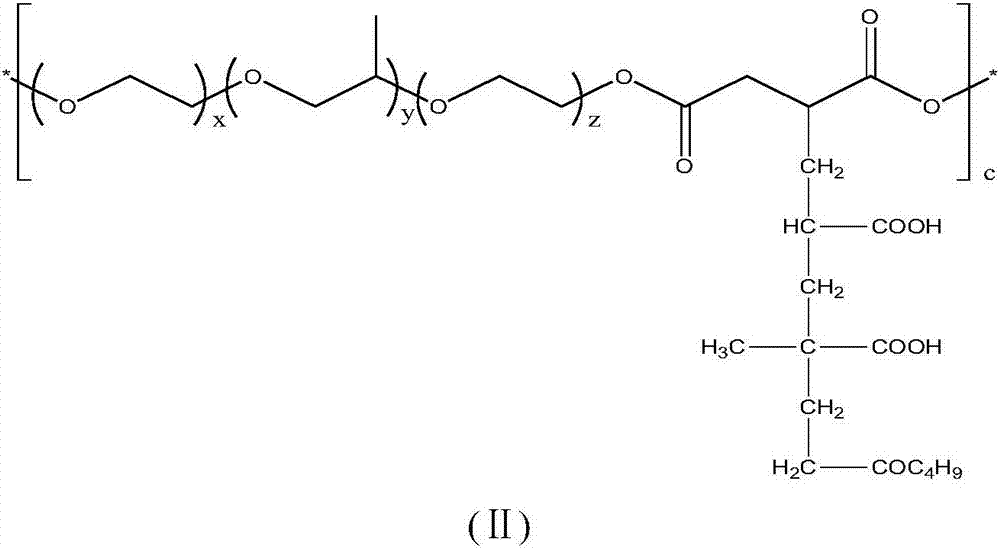

Method used

Image

Examples

Embodiment 1

[0025] 1. Preparation of main ingredient of demulsifier:

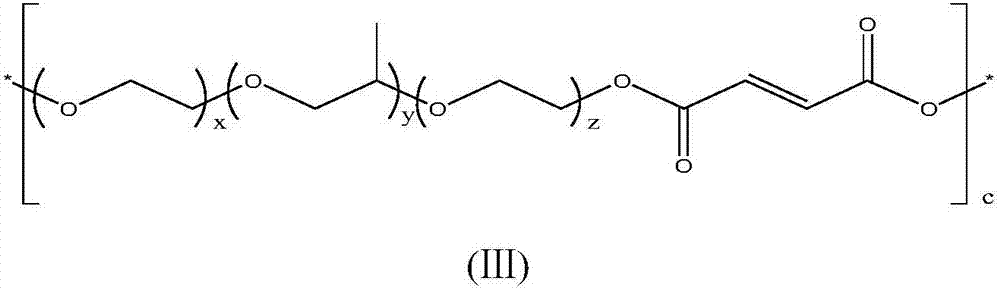

[0026] (1) In a 250mL four-necked flask equipped with a thermometer, a water separator and a reflux condenser, add 20g of polyether polyol (molecular weight around 2000), 2g of maleic anhydride (the molar ratio of polyether polyol to maleic anhydride 1:2), 0.3g p-toluenesulfonic acid (p-toluenesulfonic acid accounts for 1.5% of the total mass of the reactants) and 150mL toluene, the temperature is raised to 140°C for reaction, and the reaction progress is judged by observing the water output in the water separator. After a total time of 6 hours, a maleic acid polyether ester having the structure of the following formula (III) was obtained.

[0027]

[0028] (2) In the 250mL four-necked flask that thermometer, stirrer and reflux condenser are equipped with, add 0.2g benzoyl peroxide (benzoyl peroxide accounts for 1% of reactant gross mass) and 150mL toluene, start after Use a constant pressure titration funnel to ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com