Resistant dextrin and preparation method thereof

A technology of resistant dextrin and average molecular weight, which can be used in food ingredients as water activity modifiers, food preservation, food science, etc. It can solve the problems of unsatisfactory applications and high water activity of resistant dextrin products, and achieve shelf control period effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

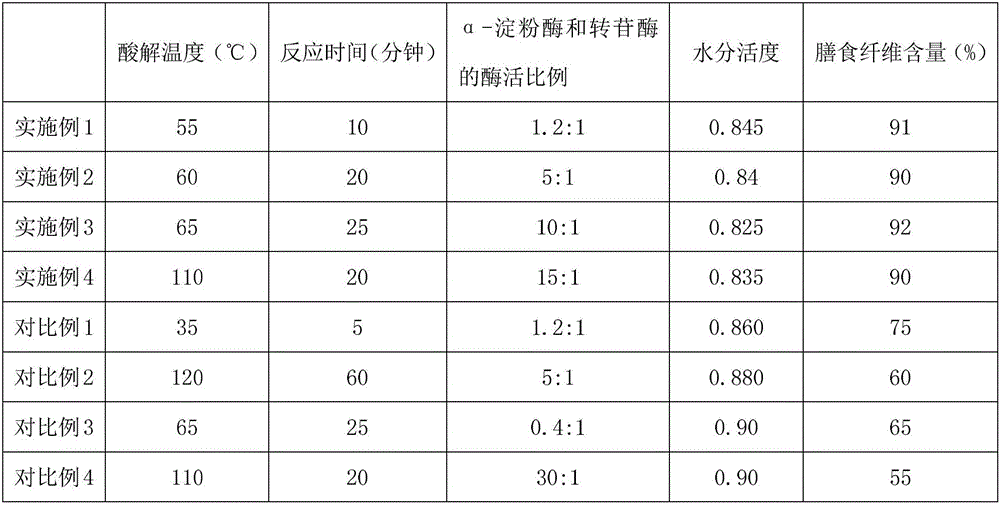

Examples

Embodiment 1

[0049] The preparation method of resistant dextrin comprises the steps of:

[0050] (1) Add citric acid with a mass of 0.01% to cornstarch, carry out high-temperature dextrinization reaction in the reactor under 130°C and -0.09MPa pressure conditions for 20min, then add deionized water to adjust the solids to 20% for acidification solution, the acid hydrolysis temperature is 55°C, the reaction time is 10min, and the DE of the acid hydrolysis solution is 15;

[0051] Then add an enzyme preparation at 0.001% by mass percentage, the enzyme activity ratio of α-amylase and transsidase in the enzyme preparation is 1.2:1, and react for 30 minutes to obtain a reaction solution;

[0052] (2) Adjust the pH value of the reaction solution obtained in step (1) to 4.5, add activated carbon in a ratio of 0.5% by mass, keep it static at 85°C for 40min, then stir for 20min; filter through a plate and frame, filter pressure 0.25Mpa, water The flow rate is 5.0t / h; the macroporous ion exchange r...

Embodiment 2

[0055] The preparation method of resistant dextrin comprises the steps of:

[0056] (1) Add citric acid with a mass of 0.02% to cornstarch, carry out high-temperature dextrinization reaction in the reactor under the conditions of 150°C and -0.095MPa pressure for 40min, then add deionized water to adjust the solids to 35% for acidification solution, the acid hydrolysis temperature is 60°C, the reaction time is 20min, and the DE of the acid hydrolysis solution is 17;

[0057] Then add an enzyme preparation in a ratio of 0.003% by mass, the enzyme activity ratio of α-amylase and transglycosidase in the enzyme preparation is 5:1, and react for 40 minutes to obtain a reaction solution;

[0058] (2) Adjust the pH value of the reaction solution prepared in step (1) to 4.8, add activated carbon in a ratio of 0.7% by mass, keep it static at 87°C for 50min, and then stir for 25min; filter through a plate frame, filter pressure 0.30Mpa, water The flow rate is 5.5t / h; the macroporous ion...

Embodiment 3

[0061] The preparation method of resistant dextrin comprises the steps of:

[0062] (1) Add 0.03% of its mass citric acid to cornstarch, carry out high-temperature dextrinization reaction in the reactor under the condition of 160°C and -0.1MPa pressure for 50min, then add deionized water to adjust the solid to 40% for acidification The temperature of acid hydrolysis is 65°C, the reaction time is 25min, and the acid hydrolysis solution DE is 18 by sampling;

[0063] Then add an enzyme preparation at 0.004% by mass percentage, the enzyme activity ratio of α-amylase and transsidase in the enzyme preparation is 10:1, and react for 50 minutes to obtain a reaction solution;

[0064] (2) Adjust the pH value of the reaction solution prepared in step (1) to 4.9, add activated carbon in a proportion of 0.8% by mass, keep it static at 88°C for 50min, and then stir for 26min; filter through a plate frame, filter pressure 0.30Mpa, water The flow rate is 5.6t / h; the macroporous ion exchang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com