A kind of parallel spinning fancy yarn and its production method

A fancy yarn, parallel spinning technology, applied in spinning machines, continuous winding spinning machines, yarns, etc., can solve problems such as spinning varieties and yarn quality restrictions, enrich appearance styles, and improve product additions. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

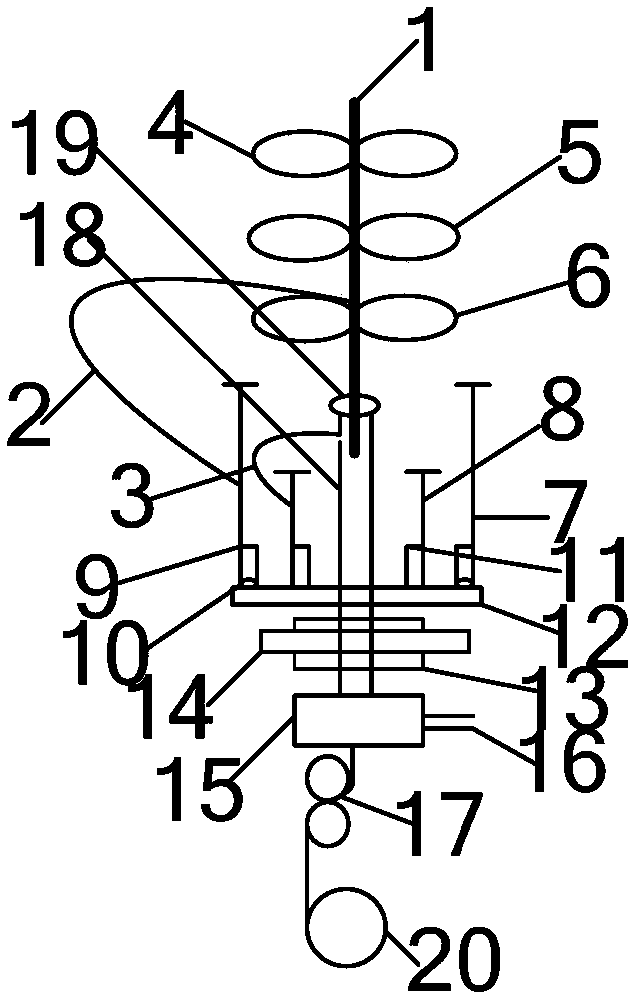

[0013] Such as figure 1 Shown, a kind of parallel spinning fancy yarn production device comprises drafting device, and drafting device comprises rear roller pair 4, middle roller pair 5 and front roller pair 6, is provided with hollow spindle 18 at the bottom of drafting device, in The hollow spindles are respectively equipped with trays 12, the trays are disc structures, the trays are fixed on the hollow spindles, and embedded pins 11 are fixedly connected to the trays. The ring at the bottom end of the pin is fixedly embedded on the tray, and the outer embedded pin 9 is connected to the tray through a bearing. On the pallet, the diameter of the cross-sectional circular surface of the external embedded pin is greater than the diameter of the cross-sectional circular surface of the internal embedded pin of the same height and the center of the circle is the same. An outer bobbin 7 is fixed, the height of the outer bobbin is greater than that of the inner bobbin, the first yar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com