A kind of yak cashmere wrapped core-spun yarn and its production method

A technology of yak wool and wrapping, applied in yarn, textile and paper making, etc., can solve problems such as spinning variety and yarn quality limitation, and achieve the effects of enriching appearance styles, improving yarn quality and increasing product added value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

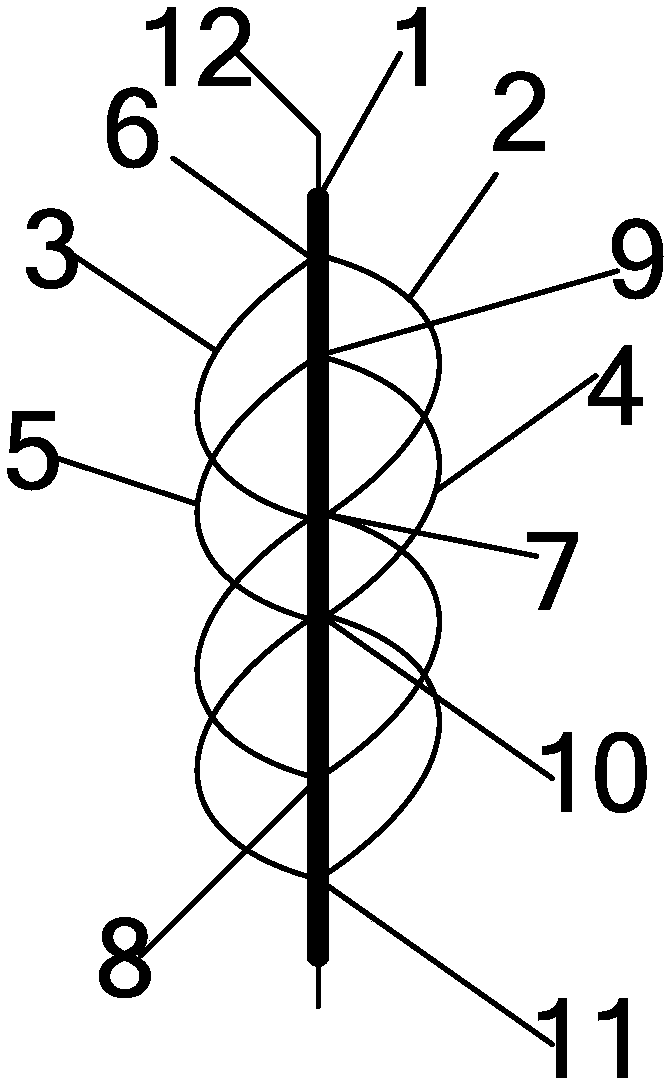

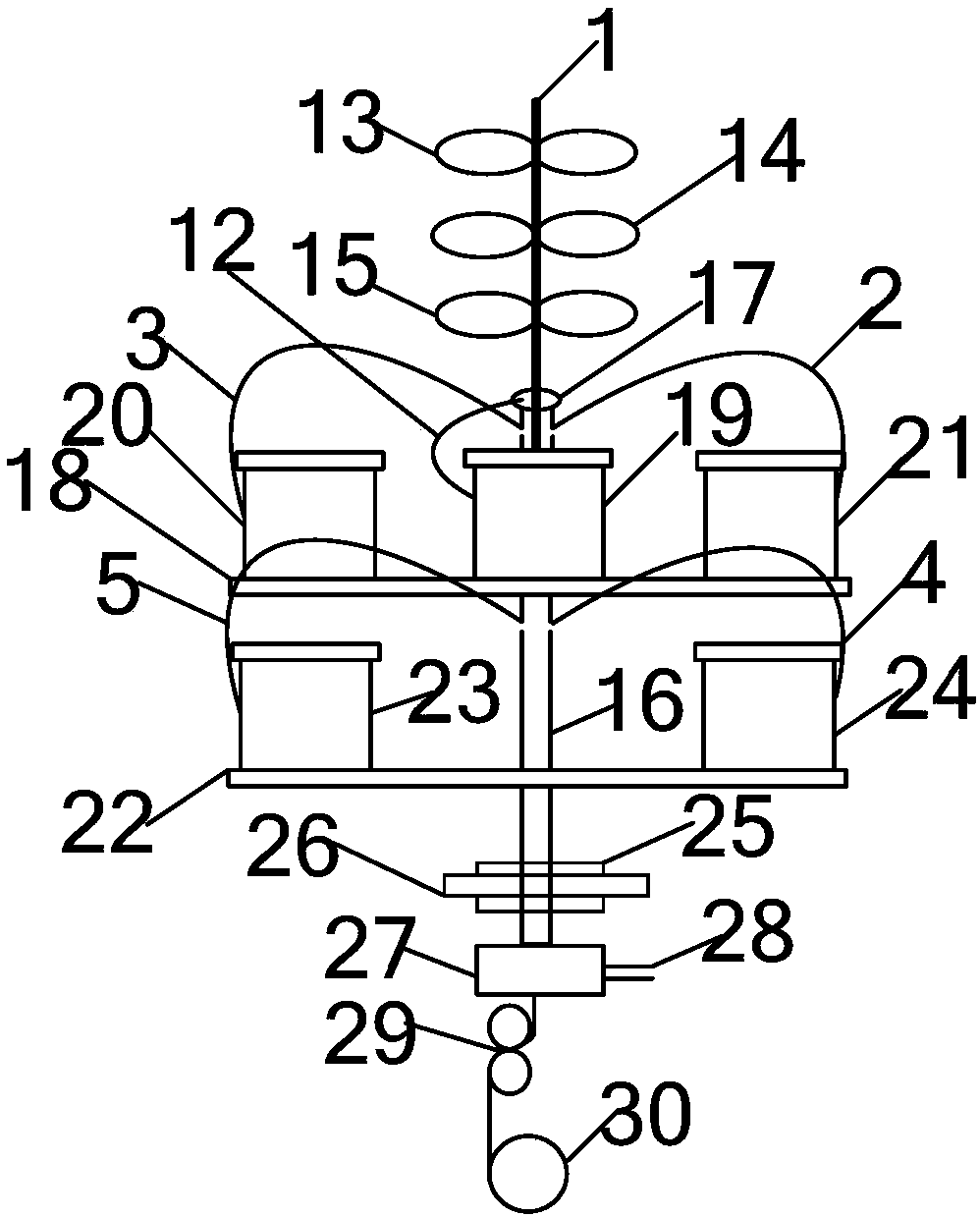

[0012] like figure 1 and figure 2 Shown, a kind of yak cashmere wraps core-spun yarn, comprises inner core yarn layer and outer wrapping layer, and inner core yarn layer comprises core layer yarn 12 and wrapping layer 1, and core layer yarn is filament or short fiber spun yarn, and wrapping layer For the staple fiber strands with weak twist, the staple strands are yak wool strands, the twist of the staple spun yarn of the core layer is far greater than the twist of the staple strands of the wrapping layer, and the outer wrapping layer wraps the first yarn 2, The second yarn 3, the third yarn 4 and the fourth yarn 5, the first yarn, the second yarn, the third yarn and the fourth yarn are identical yarns, the first yarn, the second yarn, the third yarn and the fourth yarn The yarn is filament or staple spun yarn, the first yarn is twisted in S direction and the second yarn is twisted in Z twist direction first to go around the rear side of the inner core yarn layer and intertw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com