Belt tightener

A tight belt and reel technology, applied in belt/chain/gear, greenhouse cultivation, climate change adaptation, etc., can solve the problems of poor effect stability, easy to slip, poor effect and stability, etc., to improve stability and stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

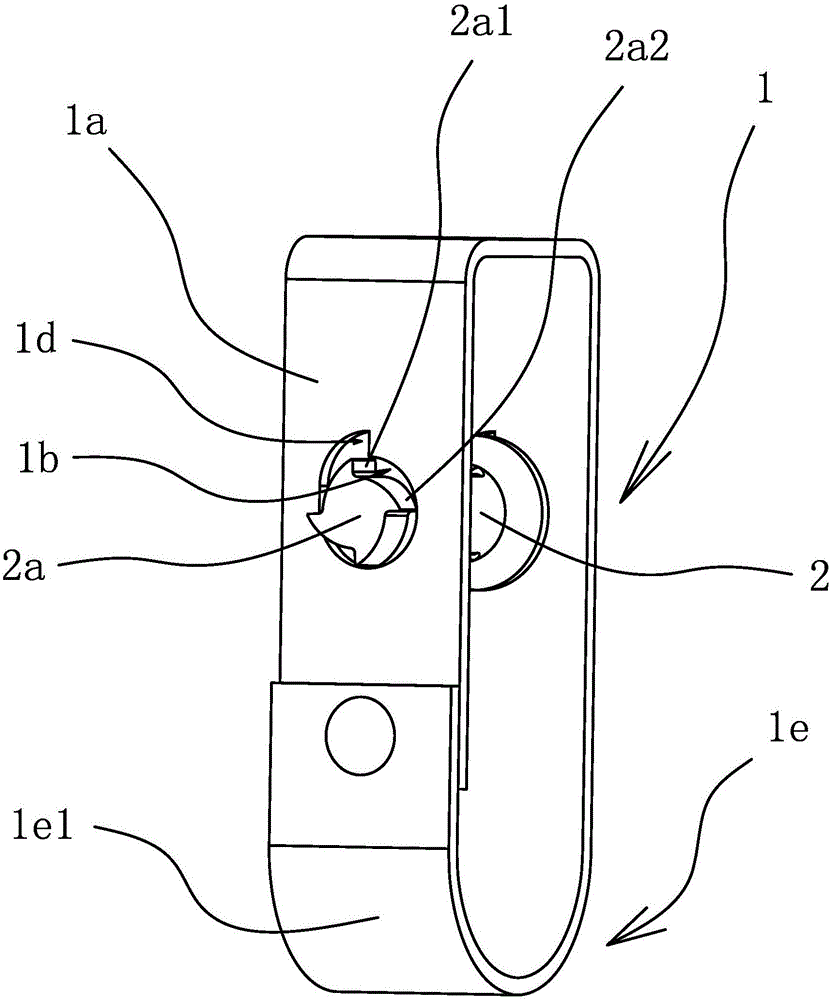

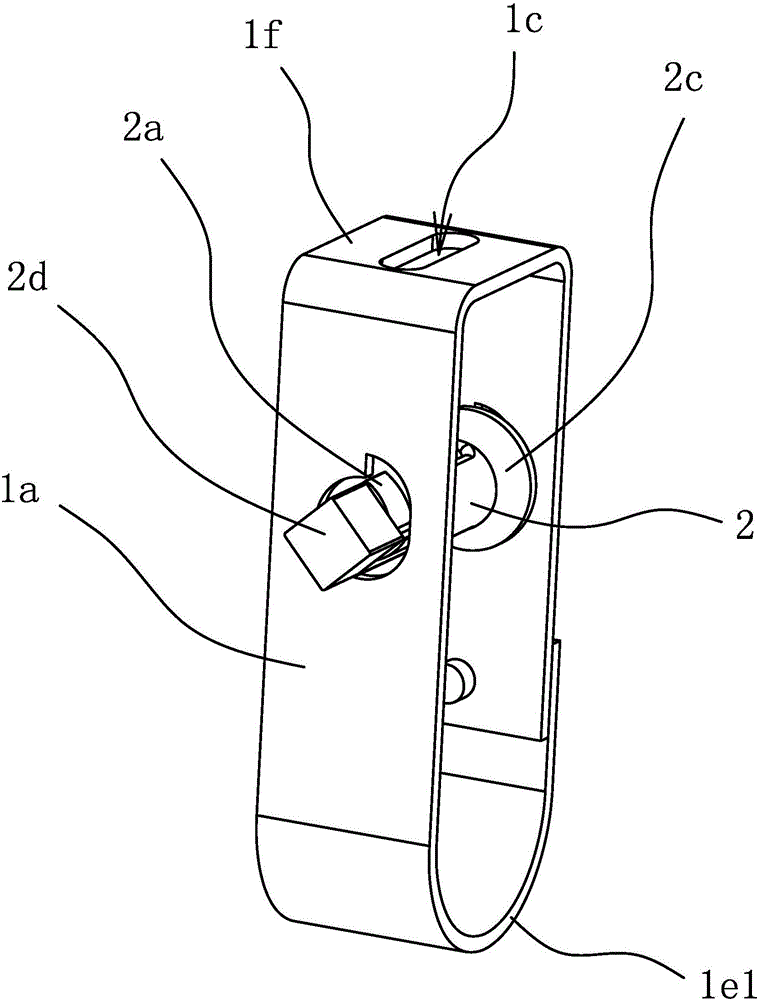

[0036] Such as Figure 1-6 As shown, the belt tightener can be used on a greenhouse, including a bracket 1 and a reel 2 . The bracket 1 has two opposite side plates 1a, a mounting plate 1f at the top, and a connecting portion 1e at the bottom that can be connected to the framework of the greenhouse.

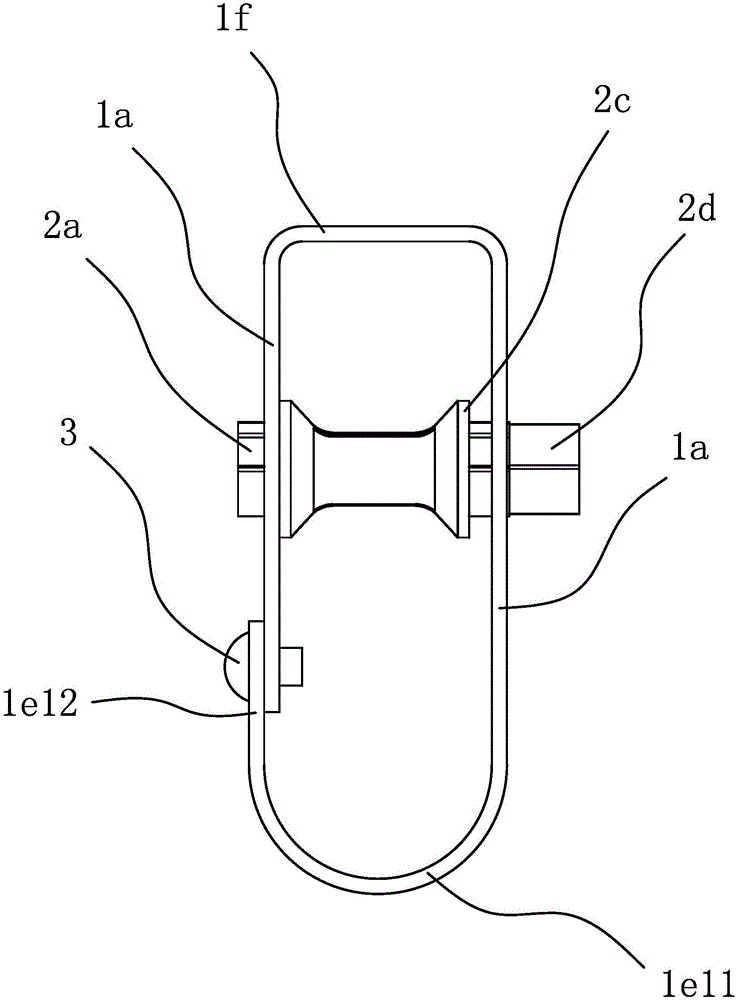

[0037] The connecting part 1e is a connecting plate 1e1, and the connecting plate 1e1 has a circular arc segment 1e11 and a flat plate segment 1e12, the circular arc segment 1e11 is connected with the lower end of one side plate 1a, and the flat plate segment 1e12 is attached to the surface of the other side plate 1a Relying on and riveting through the rivets 3, the gap between the connecting plate 1e1 and the reel 2 can be passed through by the skeleton of the greenhouse. The two ends of the mounting plate 1f are respectively connected with the upper ends of the two side plates 1a in a circular arc transition and have an integrated structure. The mounting plate 1f is provided w...

Embodiment 2

[0043] The structure of the belt tightener of this embodiment is basically the same as that of Embodiment 1, the difference is that: Figure 7-8 As shown, the lower ends of the two side panels 1a have connecting flanges 1g formed by turning inwards, and the two connecting flanges 1g are superimposed and attached to each other. The connecting part 1e is a hook 1e2, and the hook 1e2 includes a hook body 1e21 and a connecting post 1e22 located at one end of the hook body 1e21. Both connecting flanges 1g are provided with through connecting holes and the two connecting holes are oppositely arranged. The hook body 1e21 has a connecting post The end surface of one end of 1e22 abuts against the edge of the connecting hole, and the end of the connecting post 1e22 has a chamfer. The belt tightener is hooked on the crossbeam of the greenhouse frame through the hook 1e2 and then tightened and fixed by the tension force. The hook 1e2 is rotatably connected to the connecting flange 1g, tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com