Transmission shaft seal structure

A technology of sealing structure and transmission shaft, which is applied in the direction of transmission components, transmission parts, components with teeth, etc., can solve the problems of equipment appearance and environmental sanitation maintenance, leakage of sealing ring lubricating oil, waste of lubricating oil, etc. Achieve the effect of simple structure, avoid waste and prevent seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific implementation methods and accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

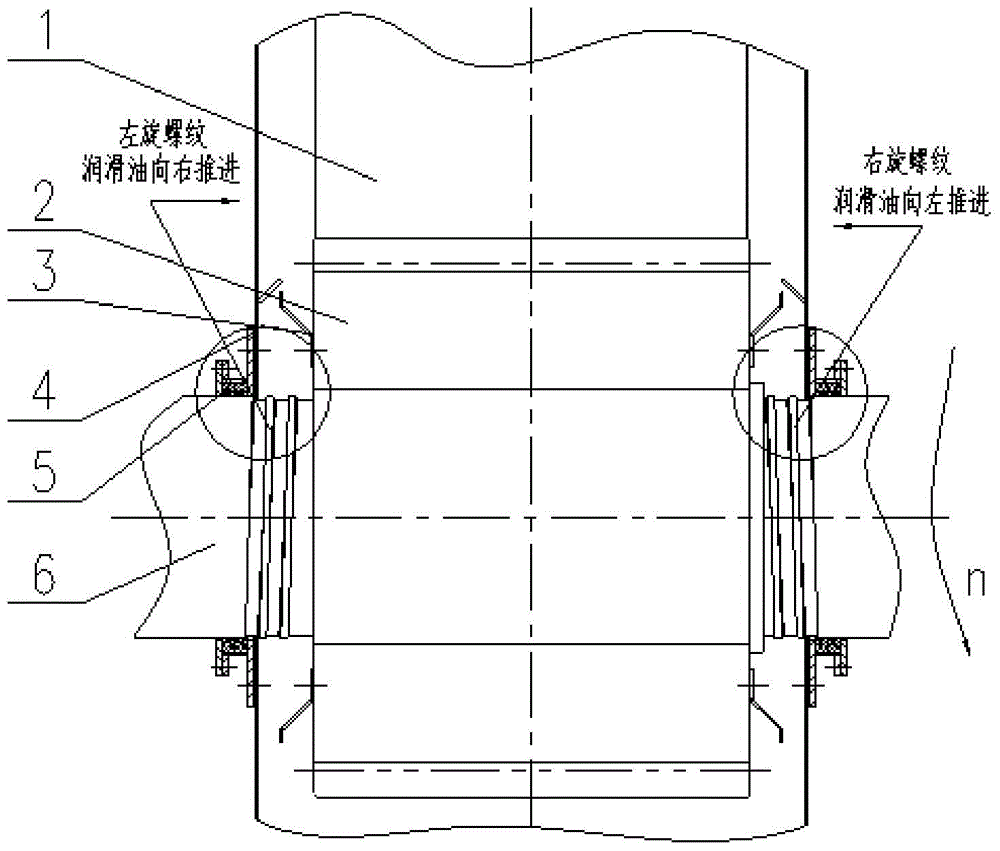

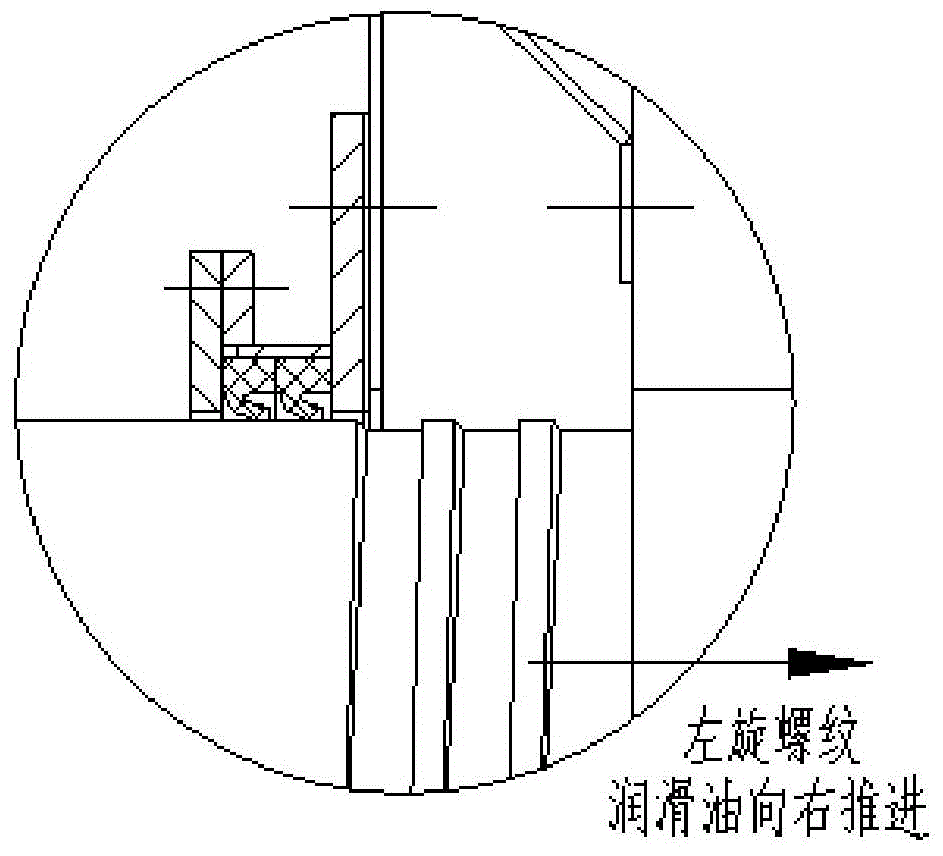

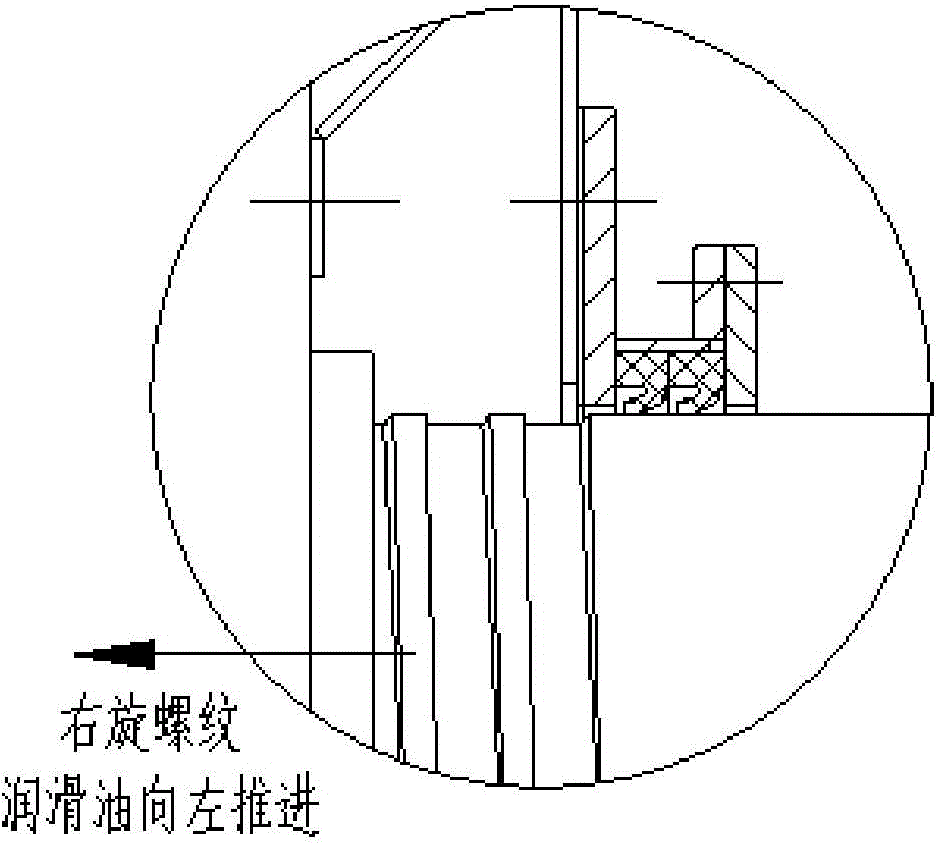

[0017] Such as Figure 1-3 As shown, the drive shaft sealing structure of the present invention is composed of a bull gear 1, a pinion 2, an oil deflector ring 3, a seal bracket 4, a lip seal ring 5 and a drive shaft 6; the pinion 2 and the bull gear 1 form Mesh connection; the pinion 2 drives the bull gear 1 to rotate; the pinion 2 is in the shape of a hollow ring; the transmission shaft 6 with threaded structure on both sides passes through the hollow part of the pinion 2, and the two form a fixed connection; Viewed from the right side to the left side, the turning direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com