Large-flow type pneumatic shut-off directional valve

A large flow, reversing valve technology, applied to valve details, multi-way valves, valve devices, etc., can solve problems such as damage, increased maintenance costs, material waste, etc., and achieve the effect of ensuring good response time and stability of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following specific descriptions of the present invention are given by the examples, which are only used to further illustrate the present invention, and should not be construed as limiting the protection scope of the present invention.

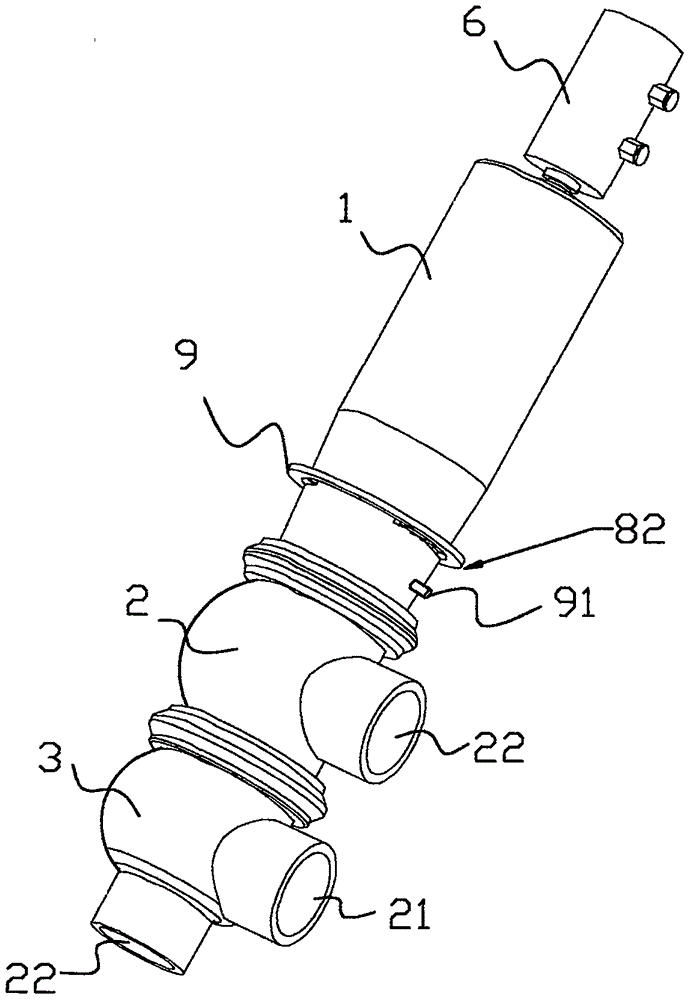

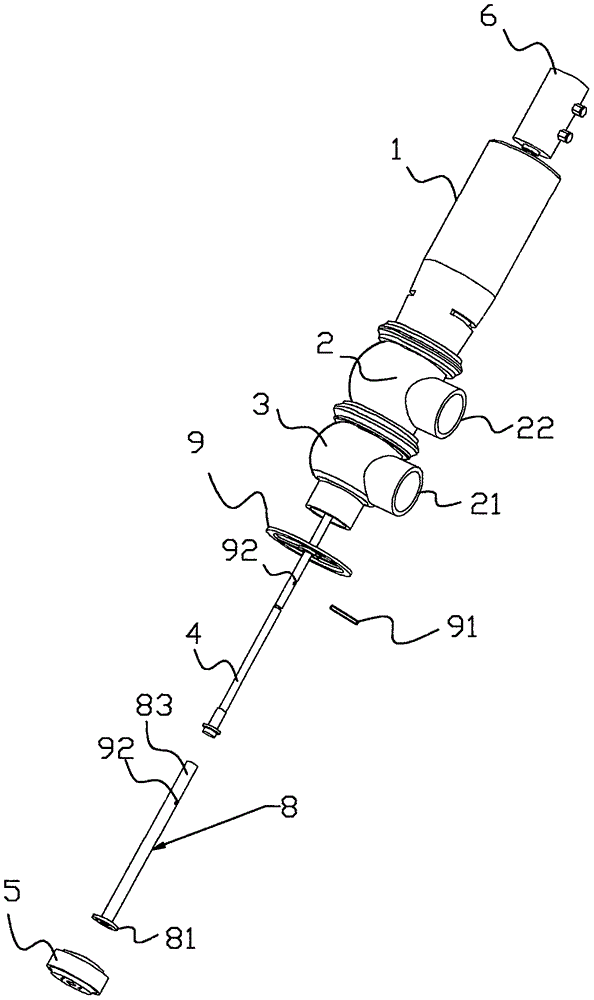

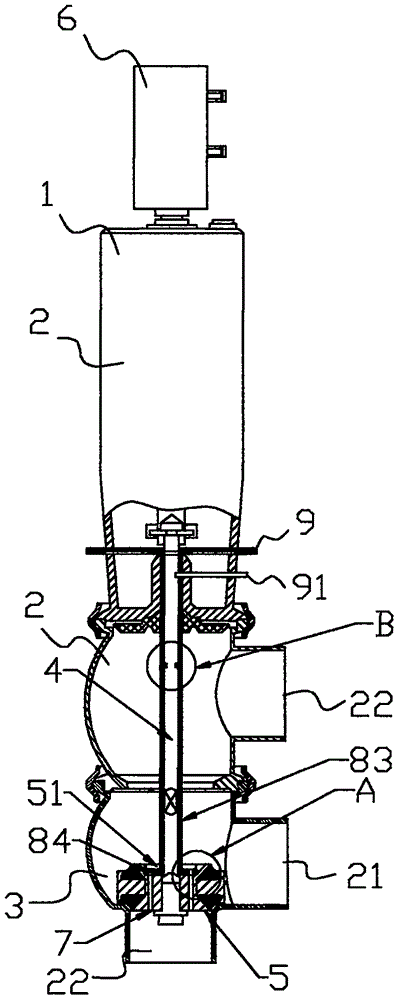

[0034] 1. If Figure 1-7The specific embodiment of the present invention shown is a large flow type pneumatic cut-off reversing valve, including a valve seat 1, an upper valve body 2 and a lower valve body 3, and the upper valve body 2 and the lower valve body 3 are respectively There is a feed port 21 and a discharge port 22 for the liquid medium to flow in or out. The valve seat 1, the upper valve body 2 and the lower valve body 3 are sequentially connected and communicated with each other. Over the upper valve body 2 and extending to the valve stem 4 in the lower valve body 3, the end of the valve stem 4 located in the lower valve body 3 is provided with a lower valve disc 5 closing the discharge port 22, the lower valve disc 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com