Feed sealing device, sealing system and installation method of wet ball mill

A wet ball mill and sealing device technology, applied in the direction of engine sealing, flange connection, mechanical equipment, etc., can solve the problems of poor sealing effect, short service life, machine wear, etc., to eliminate fouling and blockage, long service life, Guarantee the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

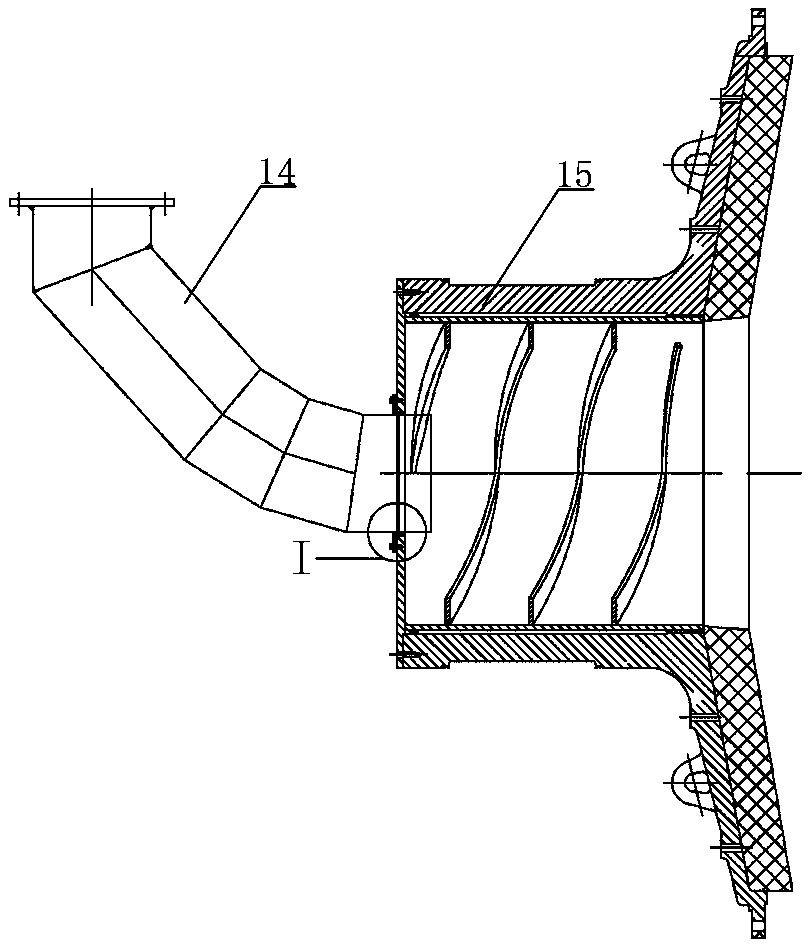

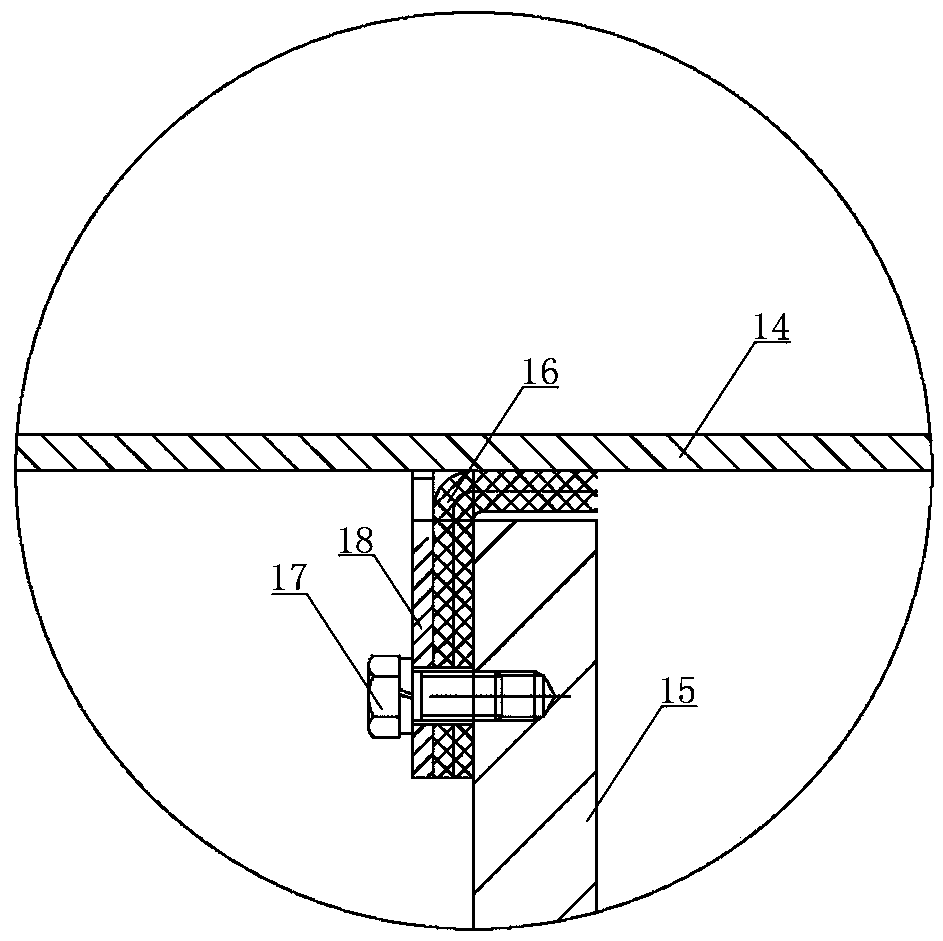

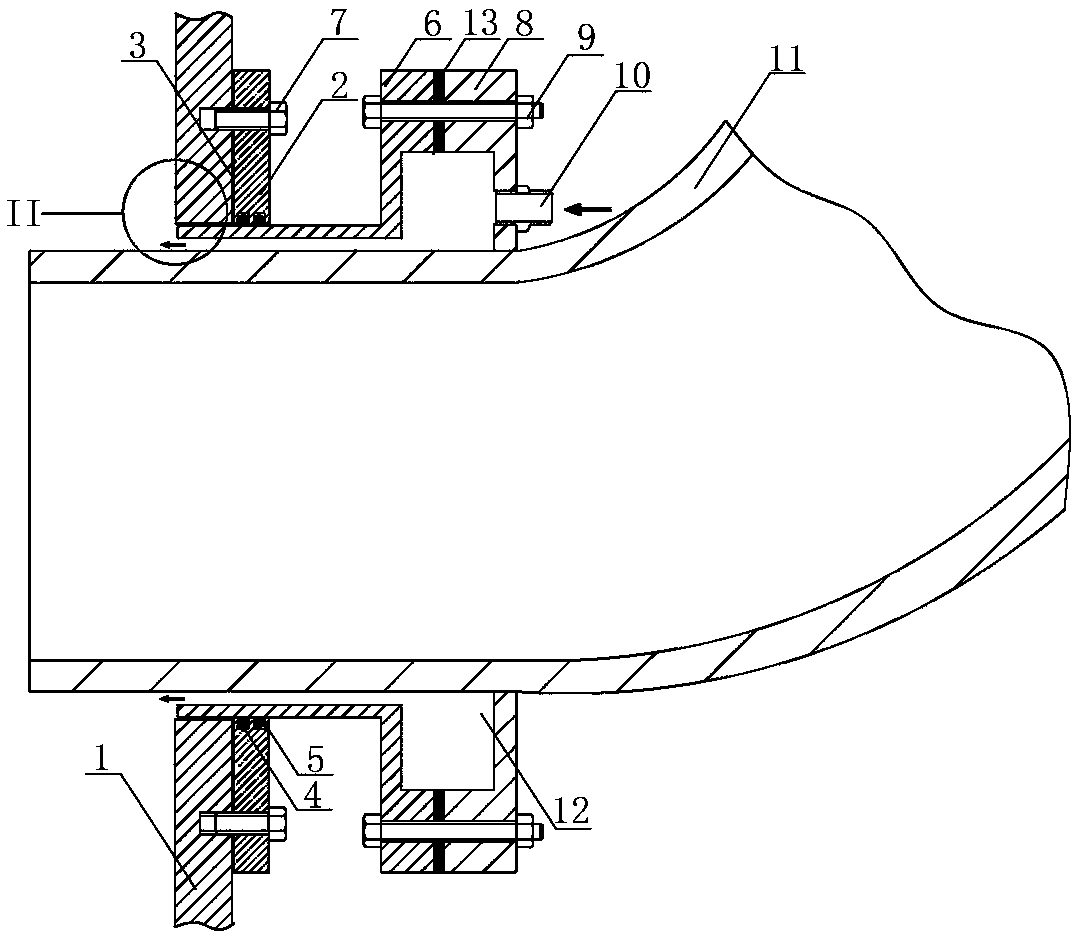

[0051] Examples see image 3 As shown, the jet sealing device of the grinding head of the wet ball mill includes jet seat 8, jet body 6, labyrinth pressure flange 2, water supply system, sealing ring, gasket and other sealing parts.

[0052] see image 3 As shown, the jet seat 8 is an integral machined component, sleeved on the outside of the feed pipe 11, see Figure 6 As shown, the jet seat 8 includes a first annular plate and a circumferentially arranged connecting flange perpendicular to the outer edge of the first annular plate, the top end of the connecting flange is flush with the upper surface of the first annular plate, and the bottom end beyond the lower surface of the first annular plate, see Figure 5 As shown, there are jet seat flange holes 81 evenly spaced circumferentially on the connecting flange; jet seat pin holes 82 are also opened on the connecting flange, and there are two jet seat pin holes 82 oppositely arranged on the connecting flange The opposite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com