Impeller type gas flow metering device

A technology of gas flow and metering devices, which is applied in the direction of measuring devices, volume metering, liquid/fluid solid measurement, etc. It can solve the problems that the impeller cannot rotate, the service life of the metering device is reduced, and the parts such as impeller bearings are easy to wear, etc., to achieve reduction Small air flow rate, protection of internal components, and the effect of ensuring filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

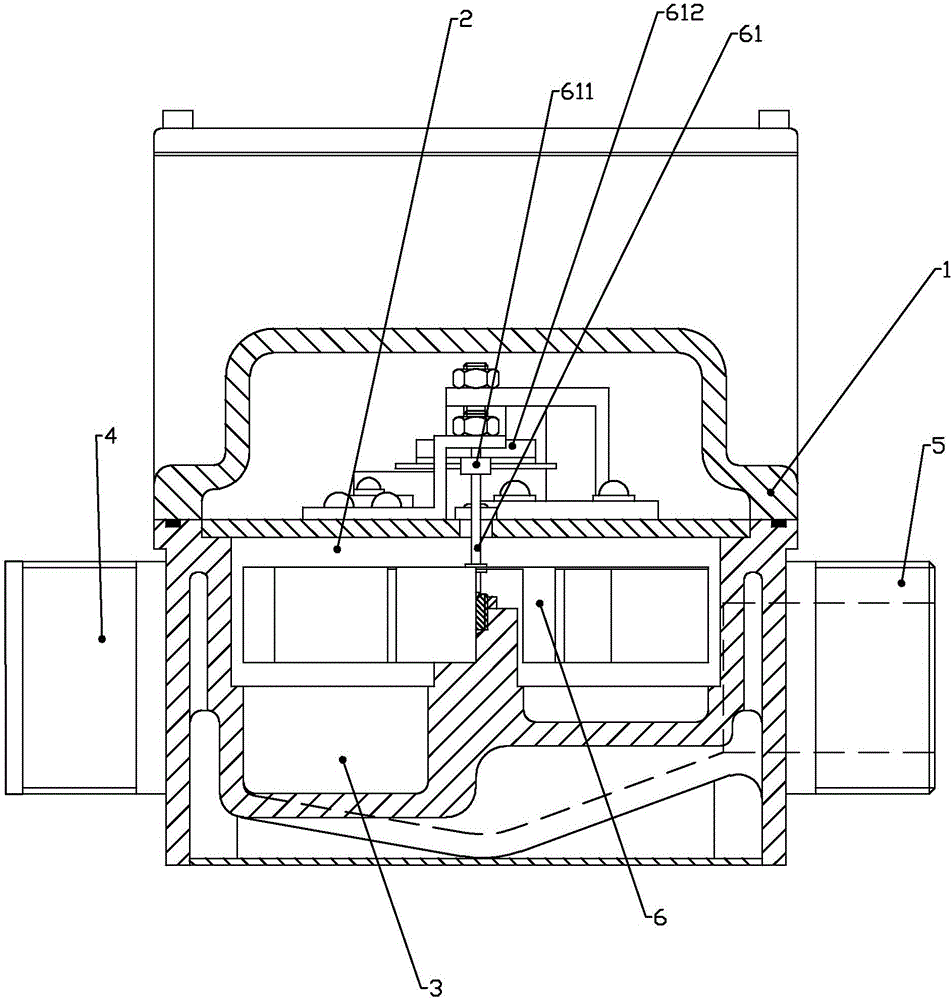

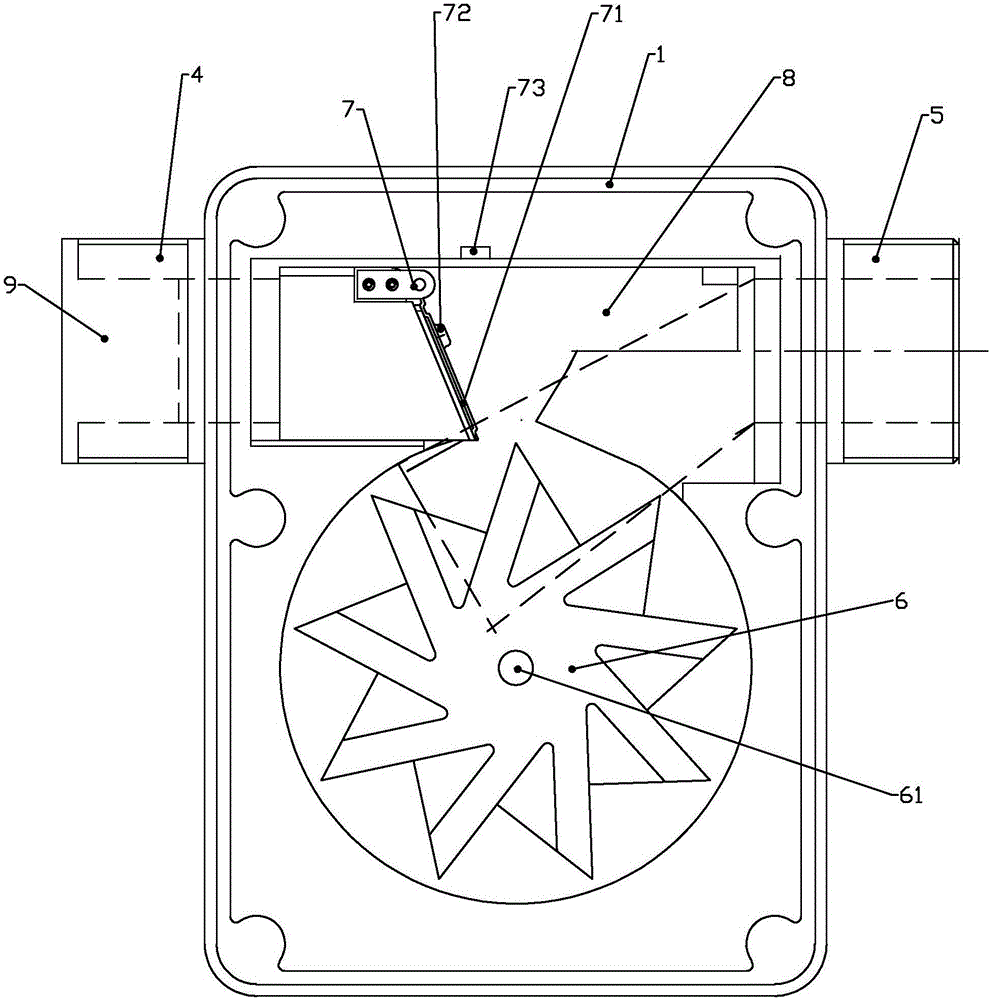

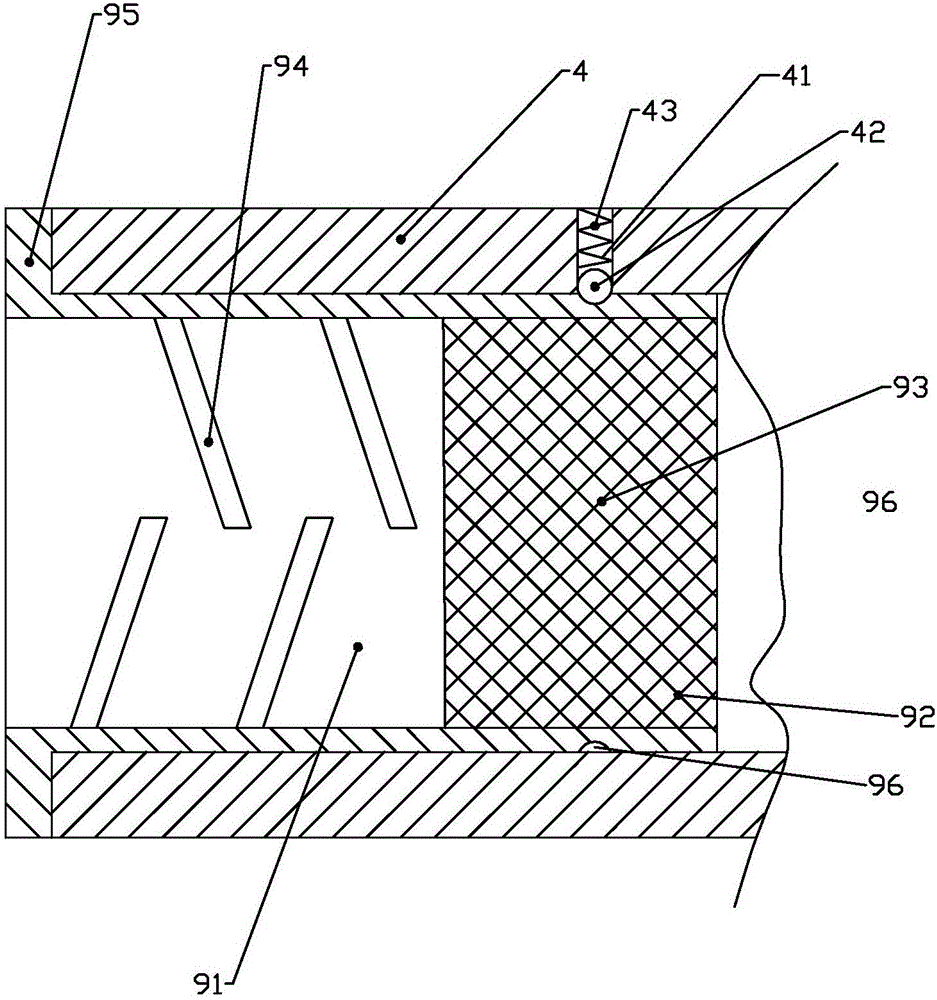

[0014] Such as figure 1 — figure 2 As shown, the present invention discloses an impeller-type gas flow metering device, comprising a main housing 1, the main housing 1 is provided with an impeller mechanism, an upper air chamber 2, a lower air chamber 3, an air intake channel 4, a valve mechanism, an air outlet Channel 5 and detection mechanism, the main casing 1 is provided with an upper air chamber 2 and a lower air chamber 3 in sequence along the vertical direction, the impeller mechanism includes a coaxially rotating impeller shaft 6 and an impeller 6, and the impeller 6 is located on the upper air chamber 2 and the lower air chamber Between the air chambers 3, the impeller shaft 61 is rotatably arranged on the main housing 1, and one end of the impeller shaft 61 extends outside the main housing 1 as a detection end 611 that cooperates with the detection mechanism. The air intake channel 4 connects the upper air chamber 2 with the outside world. The outlet channel 5 comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com