Motor of washing machine

A washing machine and motor technology, applied in the field of outer rotor type magnetic induction motors, can solve the problems of shortening the life of the motor 30, increasing the material cost, increasing the cost of the motor 30, etc., so as to prevent the decline of the motor efficiency, reduce the unit cost and reduce the material cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0095] Embodiments of the present invention will be described with reference to the drawings.

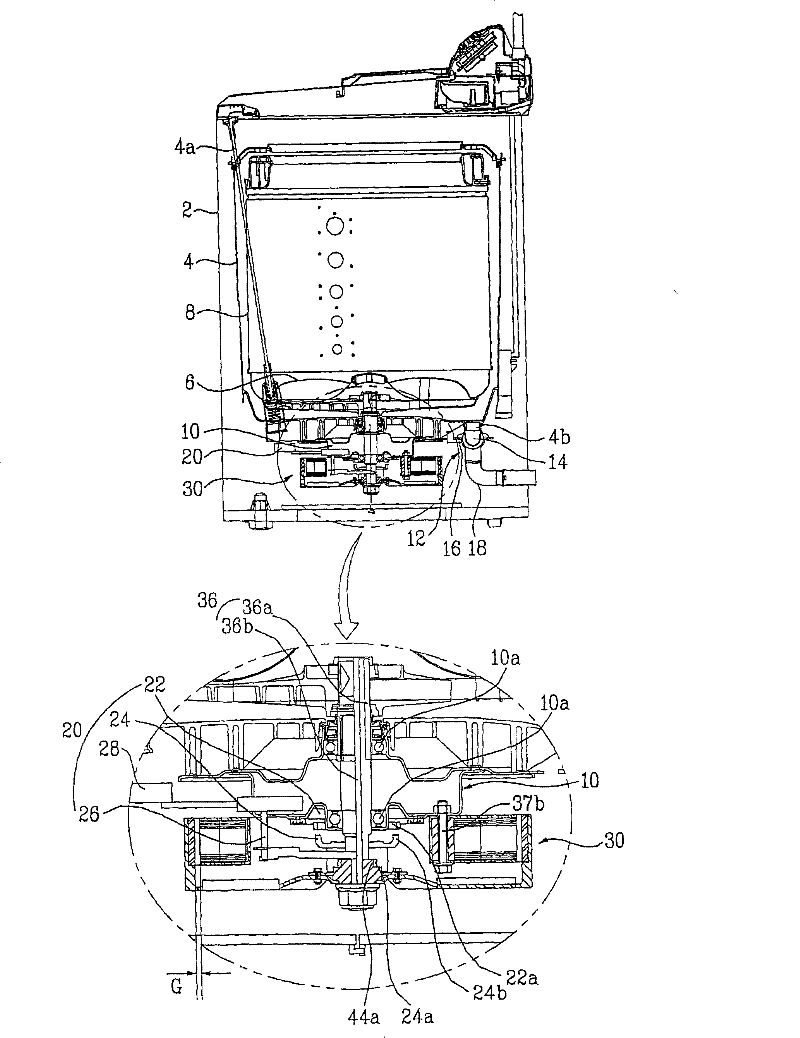

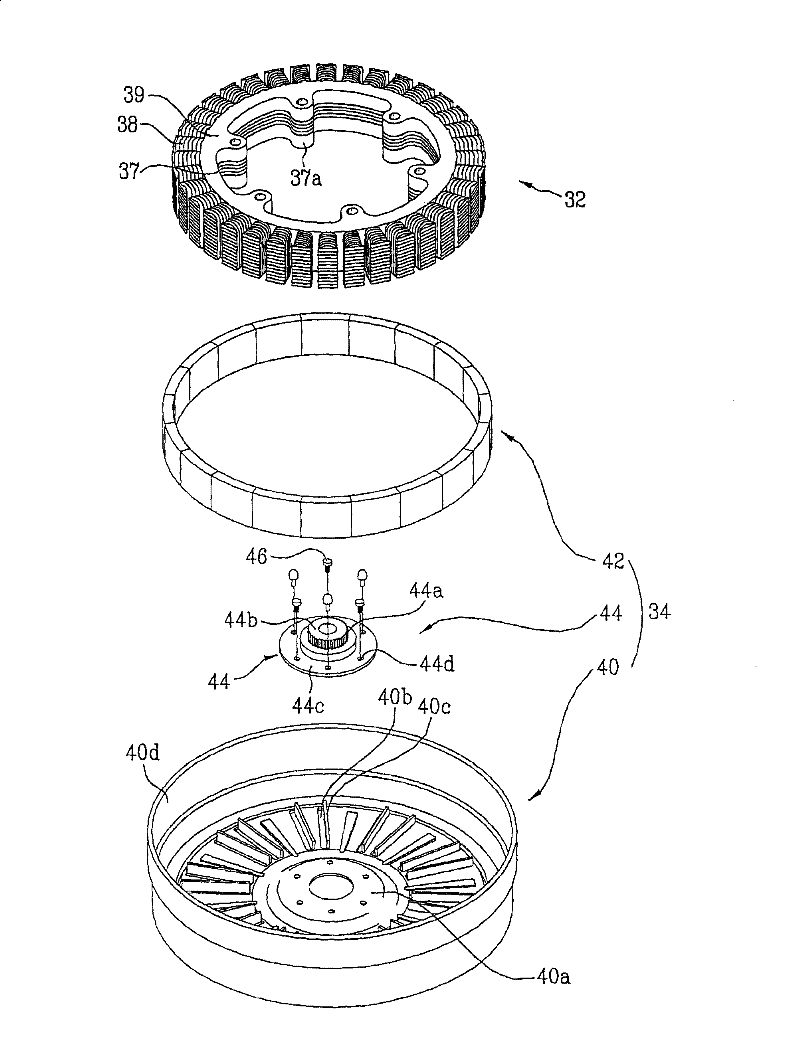

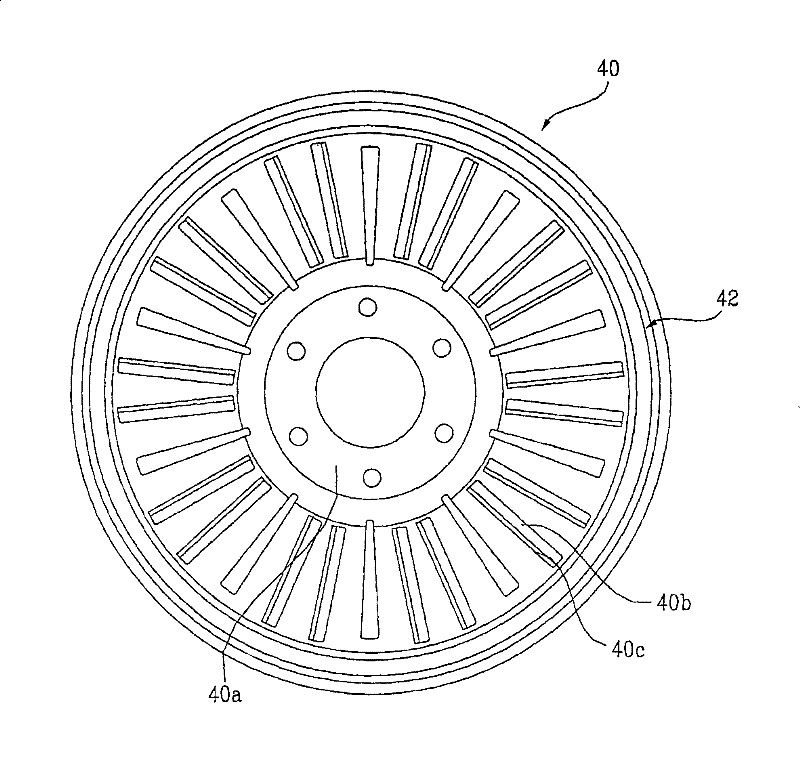

[0096] Figure 4 shows a side sectional view of a washing machine with a motor according to a preferred embodiment of the invention applied thereto, Figure 5 and 6 respectively expressed in Figure 4 Perspective and cutaway views of key parts shown in , and Figure 7 expressed in Figure 5 A cross-section of line A-A in middle.

[0097] see Figures 4 to 7 , the washing machine includes a cabinet 52 forming its exterior; an outer tub 54 suspended inside the cabinet 52 by means of a support member 54a, which has a space for holding washing water inside; an inner tub 58 rotatably mounted in the outer tub 54, with a commutator installed at its bottom 56, there are water holes on the side wall; the motor 60 located below the outer tub 54, which provides driving force to the rotating commutator 56 and the inner tub 58; and the power transmission unit 80 located between the motor 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com