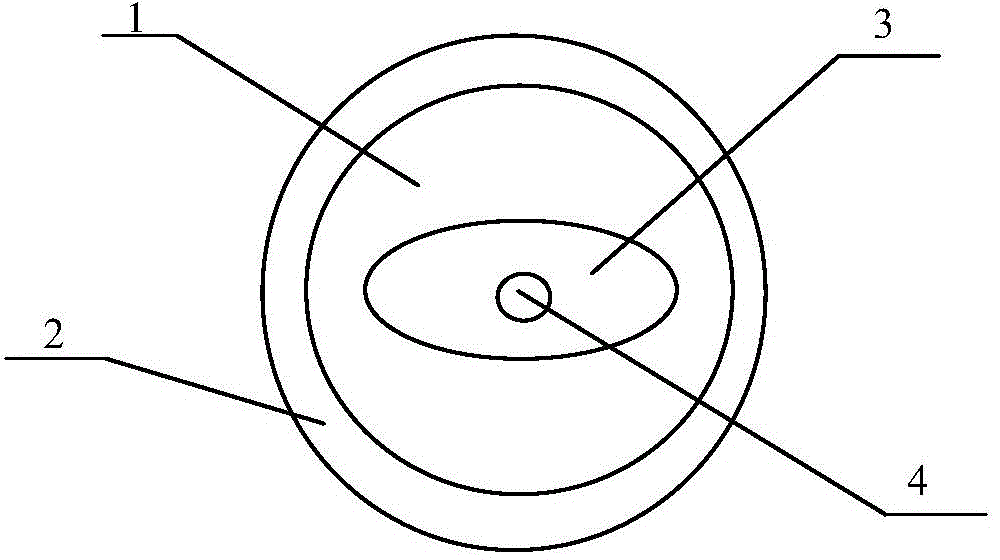

Small-diameter polarization-maintaining fiber and micro-chip fixed-shaft coupling system and method

A polarization-maintaining optical fiber and coupling system technology, applied in the direction of polarized optical fiber, cladding optical fiber, etc., can solve the problem of inability to obtain high-precision axis-fixed control, and achieve precise axis-fixed control, simple system, and accurate axis-fixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

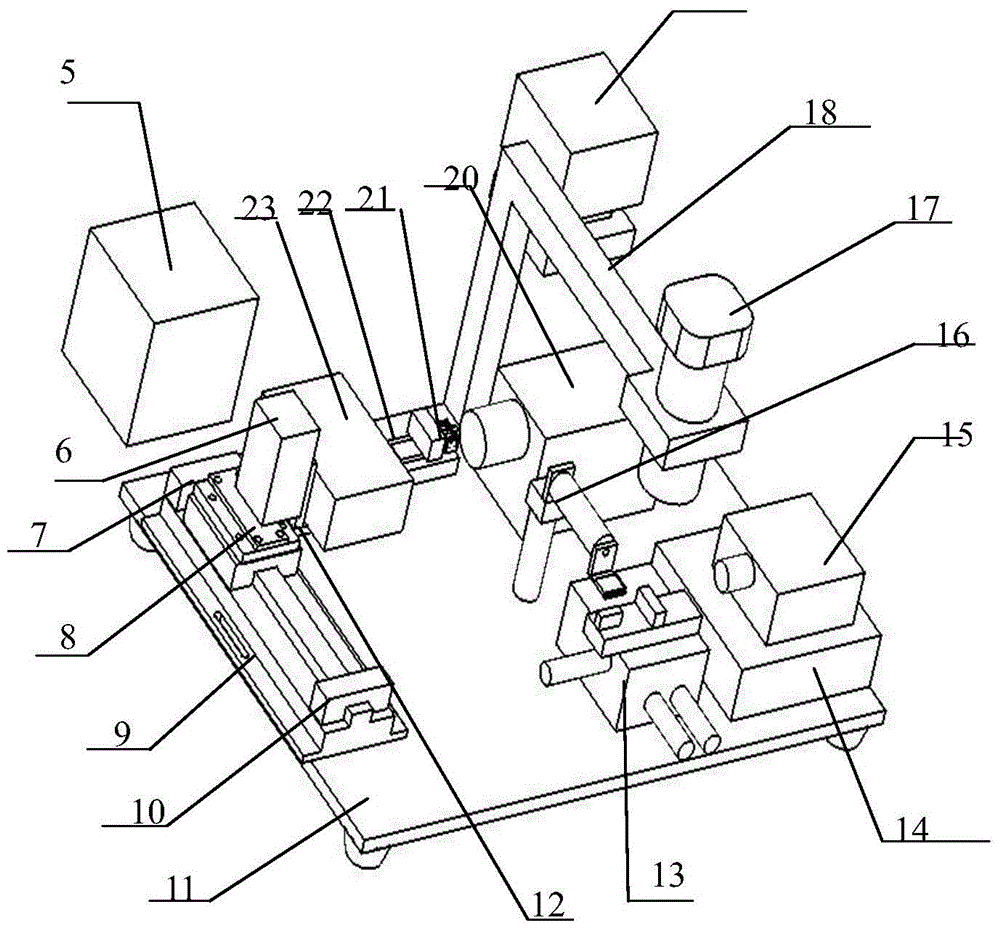

[0025] The present invention will be further described below in conjunction with accompanying drawing:

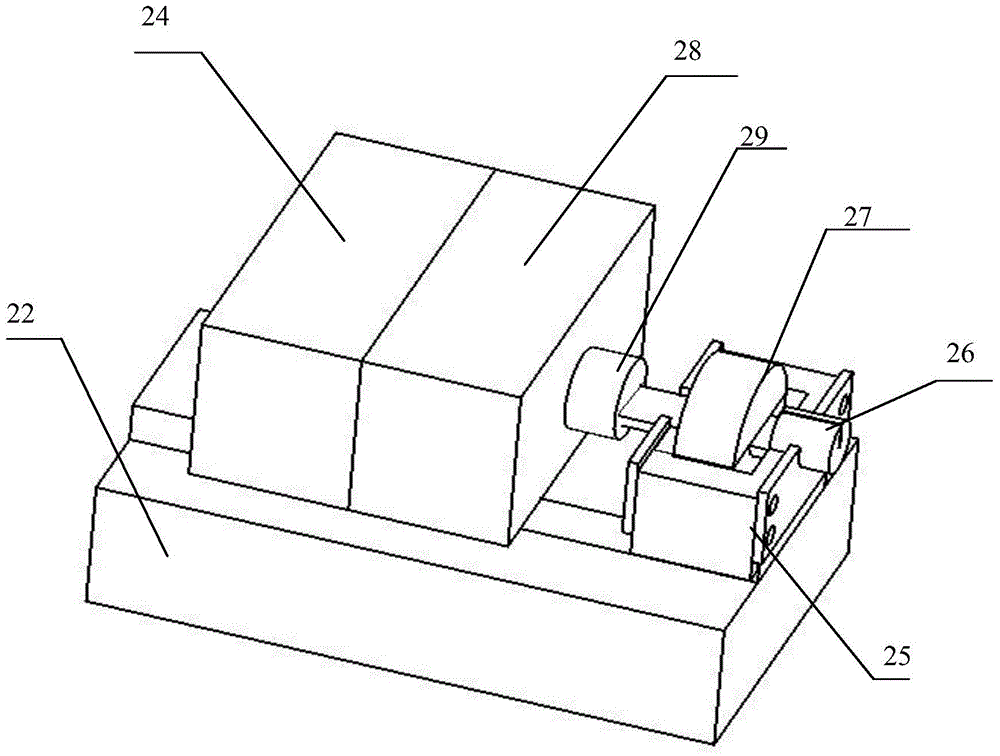

[0026] Such as figure 2 As described above, the structural optical platform 11 of the fixed-axis coupling system between the fine-diameter polarization-maintaining optical fiber and the microchip, the three-dimensional adjustment platform I6, the slider 8, the guide rail 9, the fixed base 12, the precise three-dimensional docking coupling platform 13, and the control processing system 19 , microscope III 20 , axis fixing device 21 , two-dimensional fine-tuning platform 22 , photoelectric converter 23 . Wherein, the guide rail 9 is fixed on the optical table 11, and the two ends of the guide rail 9 are equipped with a limit block I7 and a limit block II10, so as to ensure that the position of the slider 8 fixed on the guide rail 9 is constant every time it slides. The three-dimensional adjustment platform I6 and the slider 8 are fixed together, and the three-dimensional ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com