Apparatus and method for inspecting an object to be processed

A technology for objects to be processed and inspection devices, applied in the direction of nonlinear optics, instruments, optics, etc., can solve the problems of reducing the productivity of the overall process and reducing the efficiency of the process, so as to improve the process of defect causes, improve the efficiency of inspection, improve the efficiency and productive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. However, the present invention is not limited to the Examples disclosed below, and various forms different from each other can be realized. The embodiments of the present invention are provided only to make the disclosure of the present invention more complete, and are provided to inform those skilled in the art to which the present invention belongs the scope of the present invention. In order to explain the embodiments of the present invention, the drawings may be shown enlarged or exaggerated, and the same symbols in the drawings are referred to as the same elements.

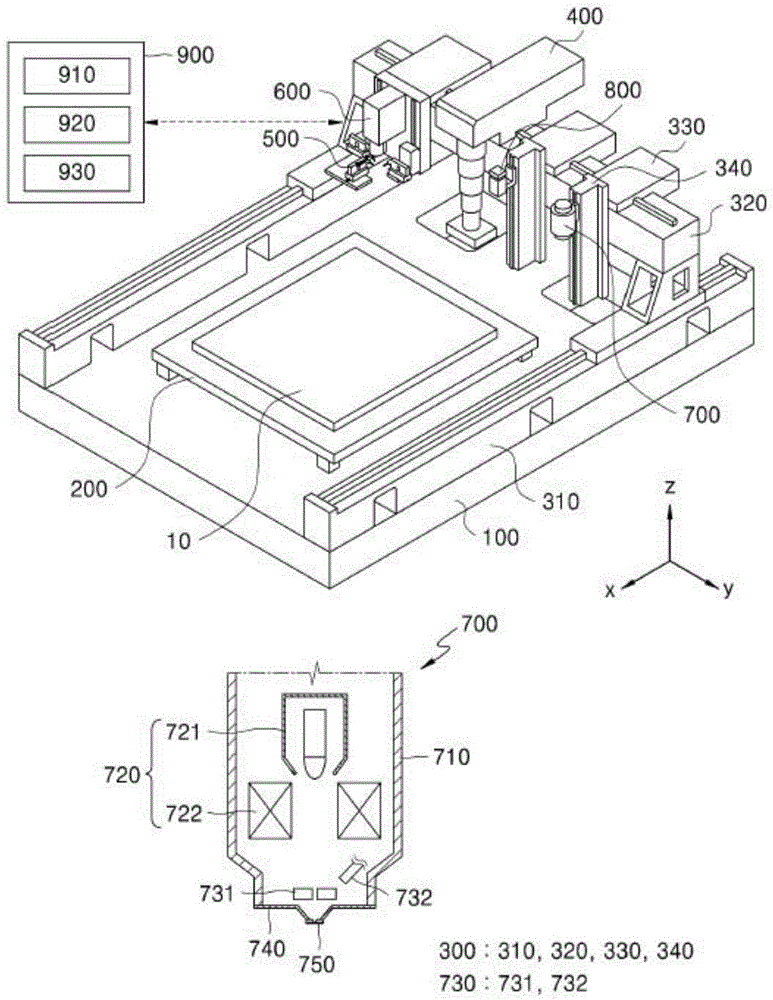

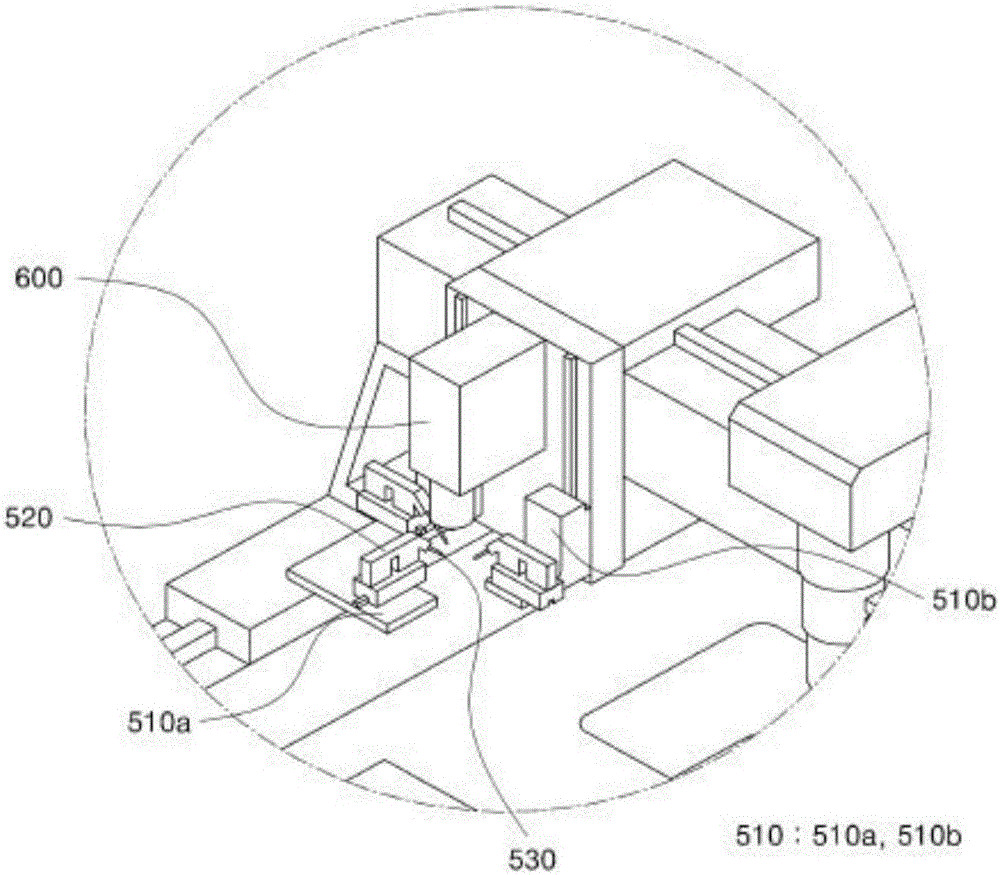

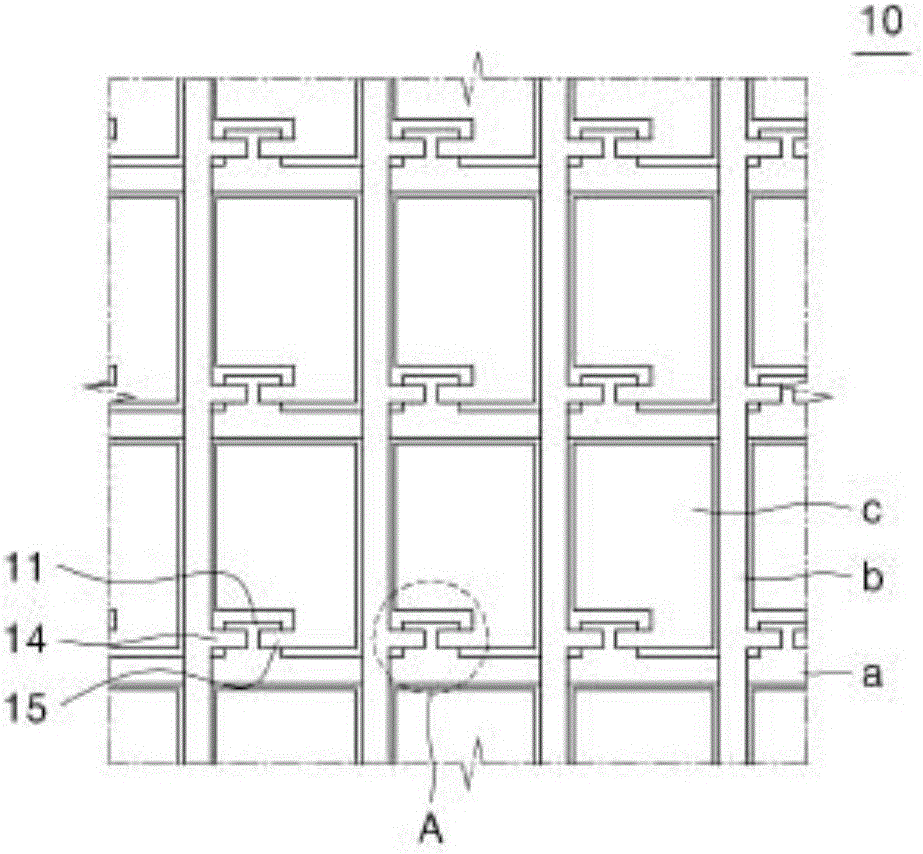

[0043] figure 1 is a schematic diagram showing an inspection device according to an embodiment of the present invention, figure 2 is a partially enlarged view showing the inspection section of the inspection device according to the embodiment of the present invention. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com