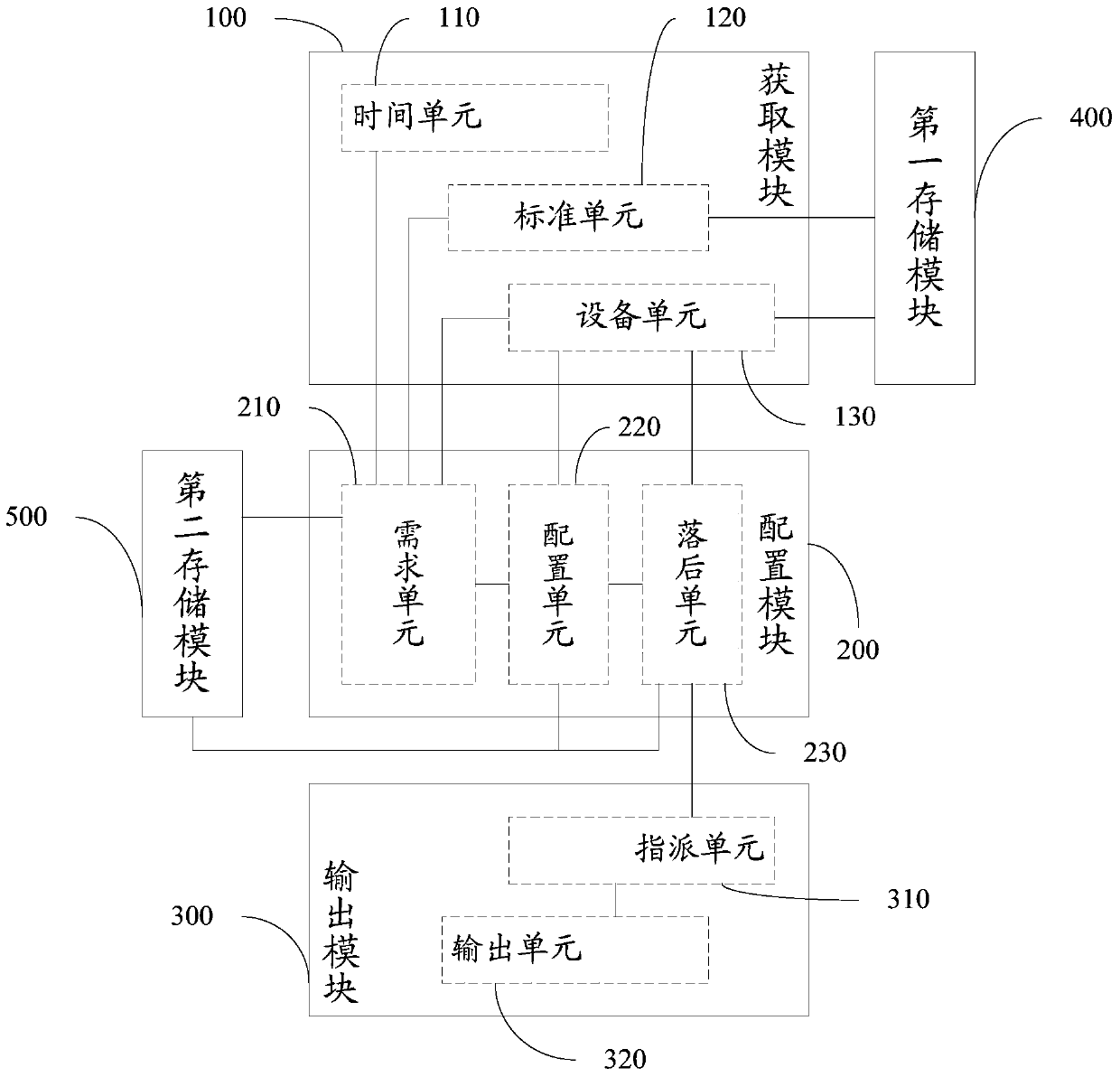

Dispatch system and dispatch method

A manufacturing execution system and process technology, applied in the field of dispatching systems, can solve the problems of long production cycle and large number of products, and achieve the effect of reducing the number of products, shortening length, and shortening production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] It can be seen from the background technology that the existing labor dispatching system has the problems of too large quantity of work in progress and too long production cycle. This is because the existing labor dispatching systems focus on the local area and only check the operation of a single device itself and its upstream and downstream equipment, while the optimization of the dispatching system only focuses on the improvement of the utilization rate of a single device, so the existing The dispatching system can only guarantee the performance of the current equipment, but cannot average the utilization rate of the equipment in the manufacturing execution system. According to the queuing theory (Queuing Theory), when the difference in equipment utilization is greater, the situation of WIP queuing is more serious, and the number of WIP in the production line is larger. Therefore, there are problems in the existing labor dispatching system in the production line that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com