Manufacturing method of cable connection terminal

A production method and wire connection technology, which are applied in the directions of connection, contact manufacturing, and components of connection devices, can solve the problems of short service life, low flexural strength, and broken connection positions, so as to reduce production costs and be difficult to break. , the effect of stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

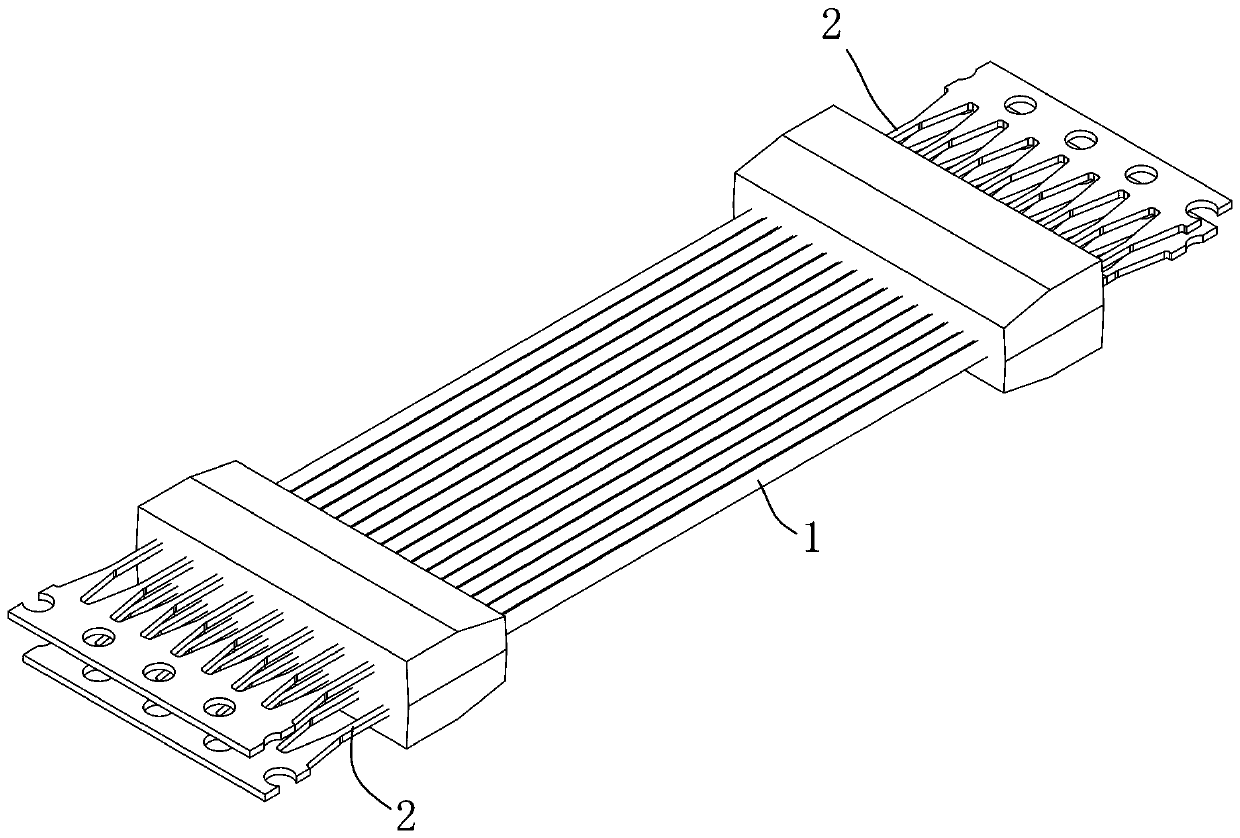

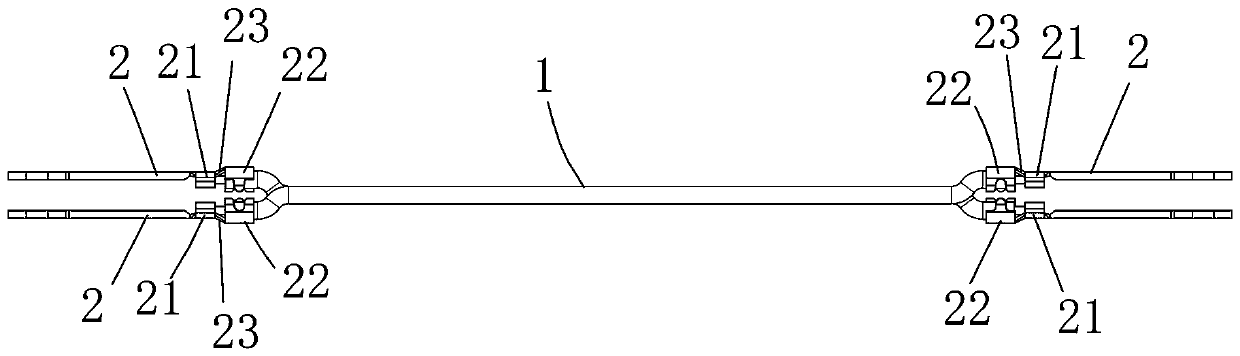

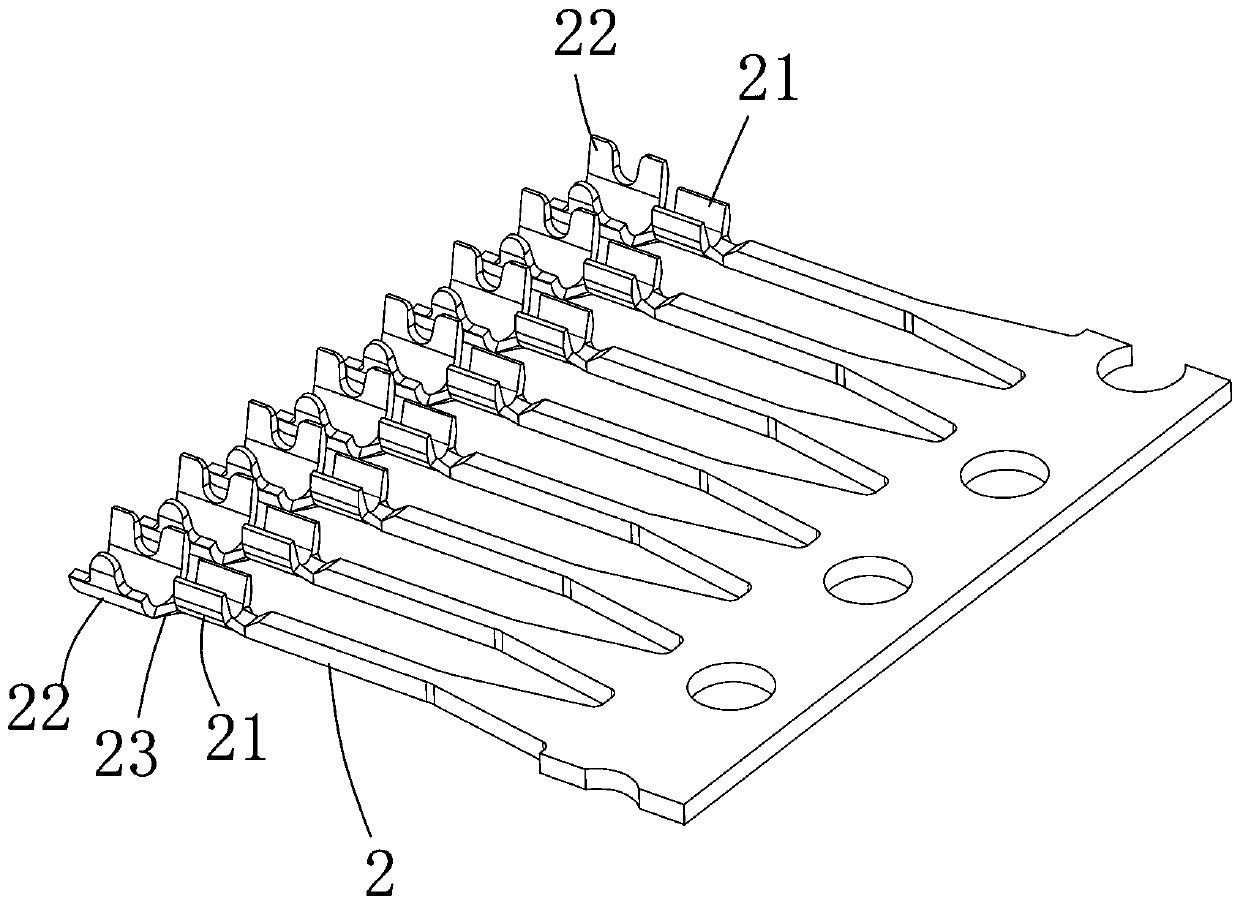

[0029] refer to figure 1 , 2 , 3, and 4, the present invention relates to a flat cable connection structure, which includes a flat cable 1 and a terminal 2, and the terminal 2 is provided with a conductive fixed connection part 21, and the conductive fixed connection part 21 is connected to the flat cable 1 and Conductive communication with the cable 1, the conductive fixed part 21 of the terminal 2 extends out a reinforced connection part 22 in the direction of the cable, the reinforced connection part 22 is fixedly connected to the cable 1, and the reinforced connection part 22 is integrated with the terminal 2 make. The additional reinforced connection part 22 is used to securely connect the cable 1 to improve the connection s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com