Method for calibrating, compensating and self-correcting parameters of optical module

A parameter calibration and parameter compensation technology, which is applied in the field of compensation and self-correction, and optical module parameter calibration, can solve the problems of inconvenient operation, high cost, and many pins, so as to improve accuracy and reliability, improve adaptability, and personnel Participation workload reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

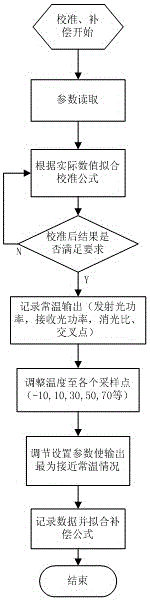

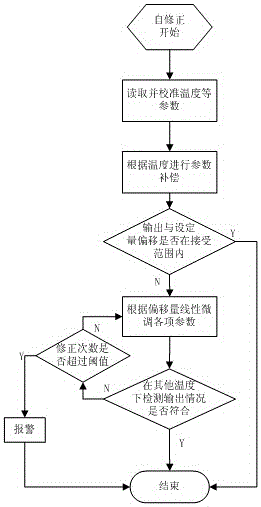

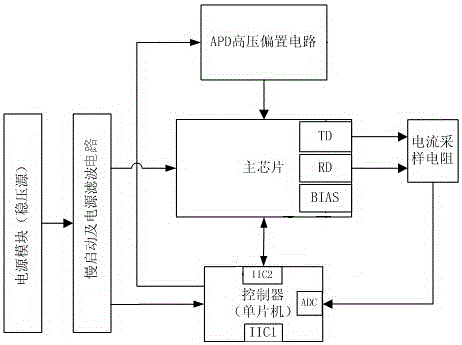

[0019] Embodiment: This embodiment is specifically described in combination with a preferred solution. The optical module in this embodiment takes 10G PON as an example. The specific implementation methods of optical module parameter calibration, compensation and self-correction are as follows: Step 1, start the optical module, burn the controller program and complete the initial configuration, confirm the host computer Communication with the controller is normal; step 2, obtain the read value of each monitoring parameter, read the temperature, voltage, transmitted light power, received light power, and bias current through the registers in the main chip. The specific operation is powered by the MCU program After initialization, it is automatically completed, stored in real-time variables, and uploaded to the upper computer regularly; step 3, obtain the actual value of each monitoring parameter, the temperature value is read out by the instrument of the high and low temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com