Method for printing individual myoporthosis resin lens based on 3D

A 3D printing and myopia correction technology, applied in the field of 3D printing, can solve the problems of uncomfortable transparent optical resin lens manufacturing, etc., and achieve the effect of convenient design and innovation, stable molding process system, and smooth and delicate surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

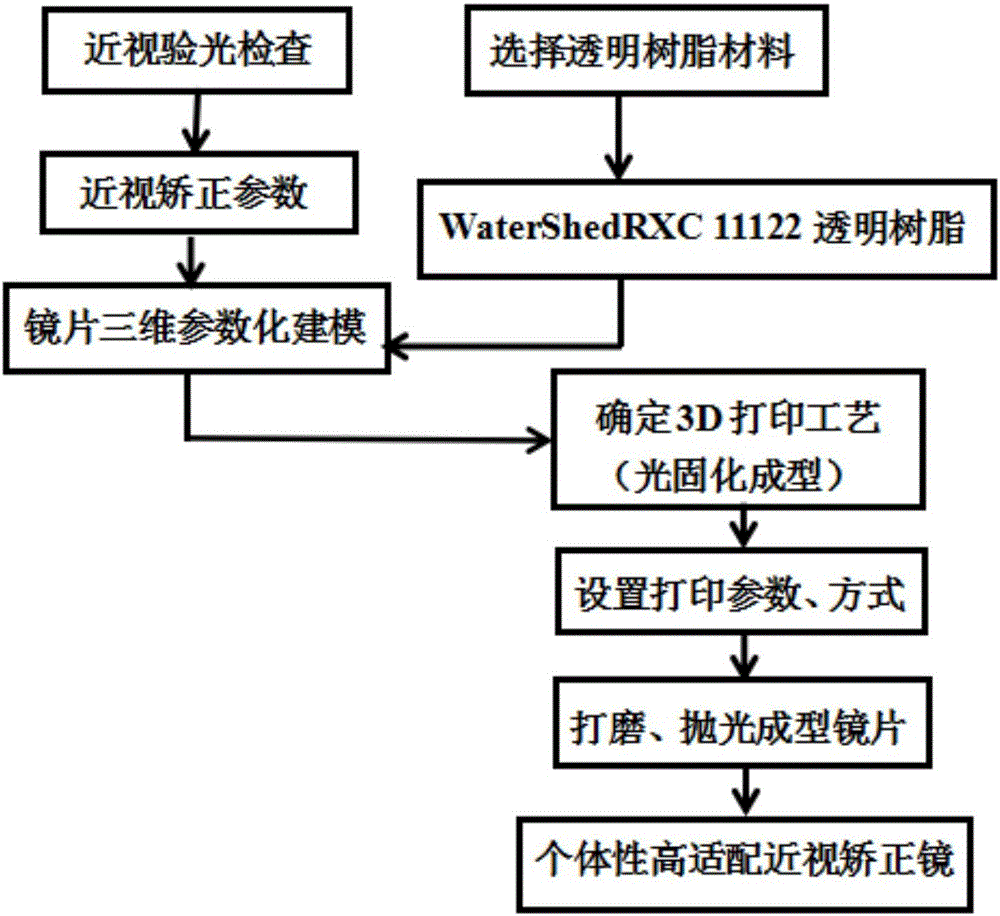

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] see figure 1 , the present invention comprises the following steps:

[0026] Step 1. According to the visual inspection parameters of myopia patients and the refractive index of the selected material, the three-dimensional model is designed according to the requirements of optical design to realize individual optical correction, and the simulation optimization is carried out in Zemax optical design software;

[0027] Step 2: Select a transparent resin material whose refractive index and other parameters meet the optical performance, and can realize 3D printing;

[0028] Step 3: Determine the 3D printing process according to the performance parameters and molding requirements of the resin material;

[0029] Step 4: According to the material performance parameters of the resin material, the printing model and the characteristics of the printer, set the appropria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com