Novel integrated thermal compounding three-phase separator

A technology of three-phase separator and thermal compounding, which is applied in the chemical and petroleum fields, can solve the problems of incomplete separation and achieve the effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

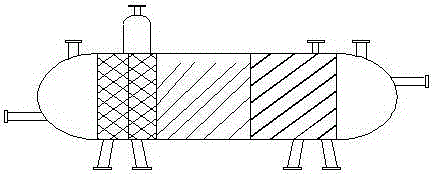

[0043] A new type of integrated thermal composite three-phase separator, which is composed of a separator, a gas purifier, a sand removal and mechanical impurity removal system, a meter, a regulating valve, and a burner are connected in sequence. The separator adopts a double torch to directly There are two sets of heating methods, and they are equipped with separate chimneys and burners.

[0044] The separator is arranged in parallel with two heating torches with lower power to ensure uniform heating effect.

[0045] The flame cylinder is located in the emulsion medium and is U-shaped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com