Energy-saving flushing and sweeping truck

A technology for cleaning vehicles and vehicle frames, applied in the field of sanitation vehicles, can solve the problems that the battery power of electric sanitation vehicles cannot be continuously supplied, the distribution of special charging equipment is small, and the vehicles are broken down in the middle of the road, etc. The effect of high speed and control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

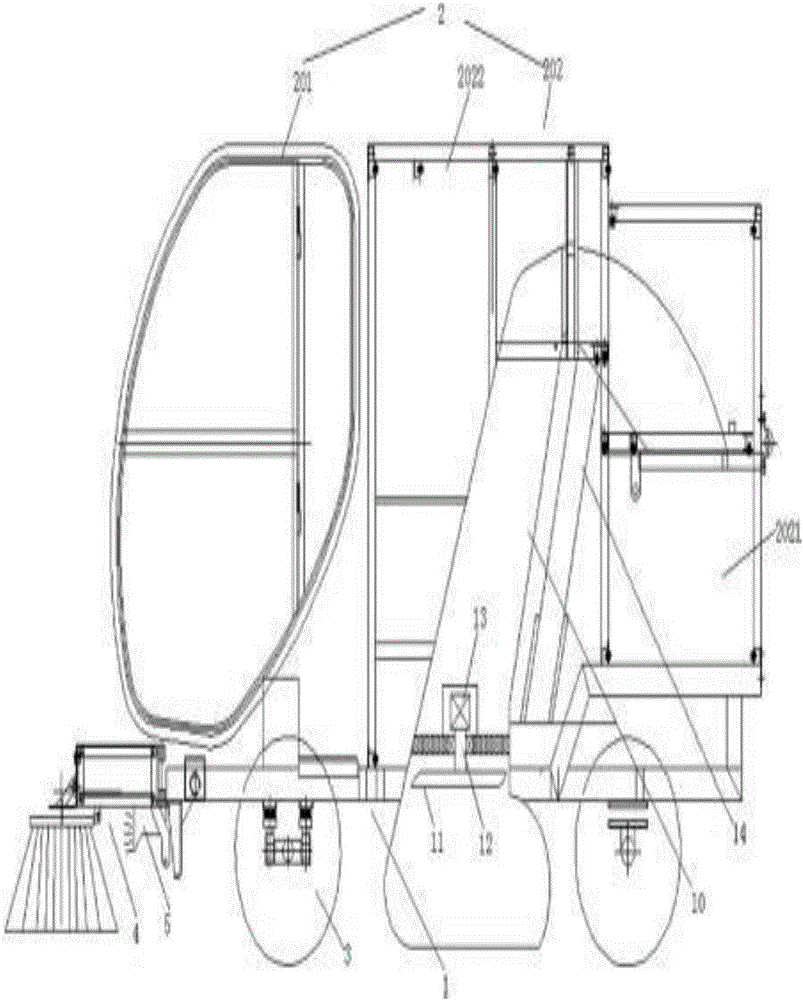

[0012] Referring to the accompanying drawings, an energy-saving washing and sweeping vehicle includes a base 1, a vehicle frame 2 and its wheels 3, the vehicle frame 2 is arranged on the base 1, the wheels 3 are arranged on the base 1 through the axle 301, and the front end of the vehicle frame 2 is provided with a sweeper. The brushing mechanism 4, the brushing mechanism 4 includes two front brushes 401 and two side brushes 402, the two front brushes 401 are respectively arranged on both sides in front of the two side brushes 402, and the two side brushes 402 pass through the fixed plate 403 Fixed on the front end of the base 1, there are telescopic cylinders 404 on both sides of the fixed plate 403, the front ends of the telescopic cylinders 404 are connected to the front brush 401, the brushing mechanism is provided with a water mist nozzle 5, and the water mist nozzle 5 is connected to the water tank and the gear pump through pipelines 6. The front and rear wheel shafts 7 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com