A prefabricated concrete drainage structure inside a rockfill dam body and its construction method

A prefabricated concrete and drainage structure technology, which is applied in the direction of infrastructure engineering, dams, barrages, etc., can solve problems such as inability to overhaul, affect the safety of the dam body, and high dam infiltration line, so as to achieve lower water level, reliable drainage effect and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

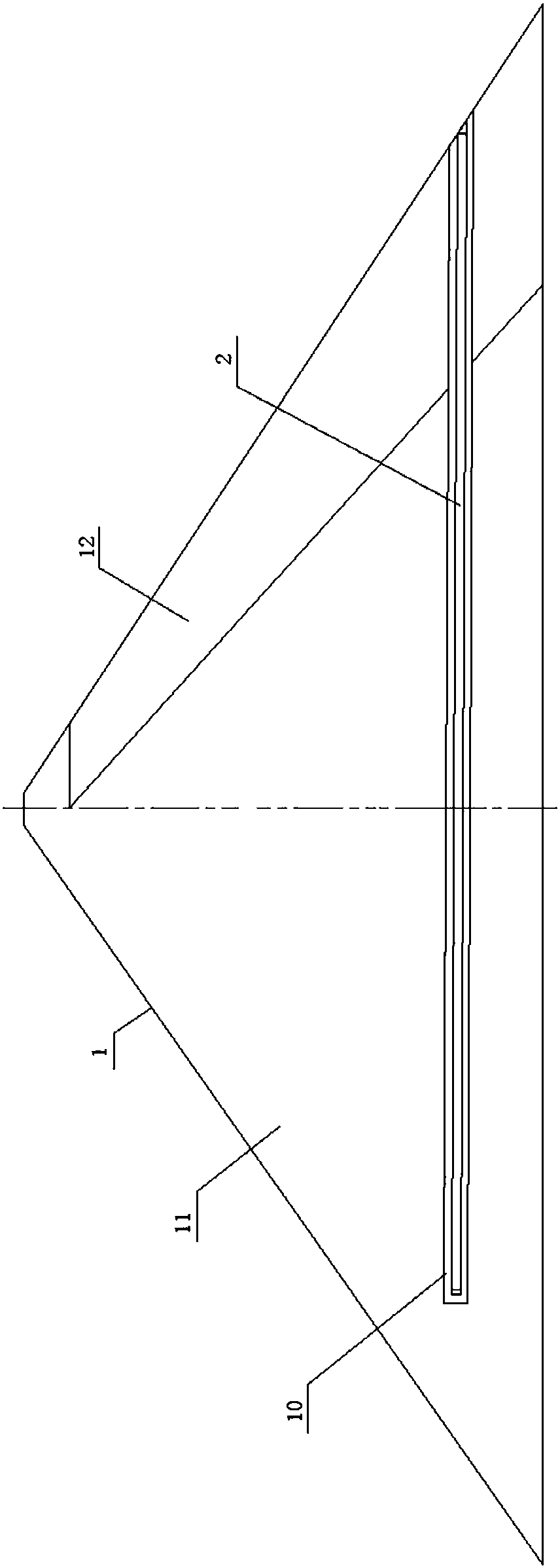

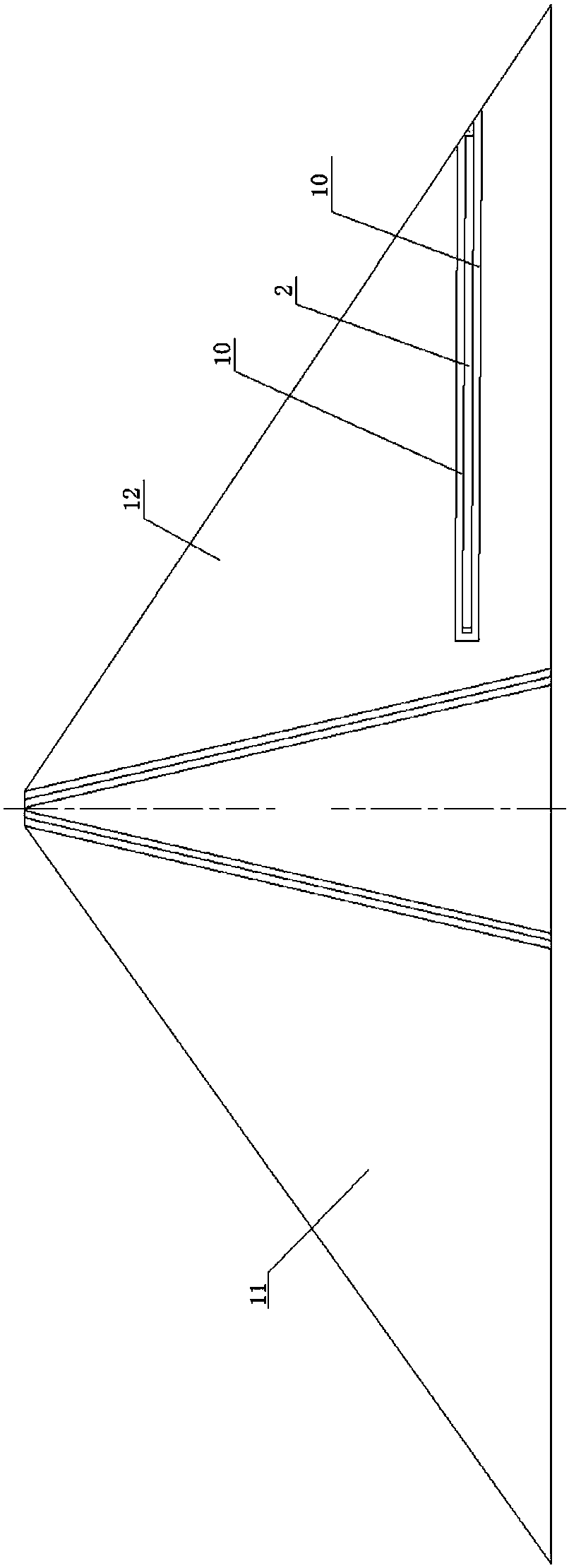

[0028] In order to overcome the defects in the prior art that the dam body is not well drained, the soaking line is high, and cannot be repaired, which seriously affects the safety of the dam body, this embodiment provides a method such as Figure 1-2 The prefabricated concrete drainage structure inside the rockfill dam body shown includes a prefabricated concrete drainage body 2 horizontally arranged on the rockfill dam body 1; the rockfill dam body 1 has a wetting line formed due to leakage of the dam body, The prefabricated concrete drainage body 2 is located below the dam soaking line; the prefabricated concrete drainage body 2 is a hollow reinforced concrete thin-walled structure, which is formed by connecting a plurality of prefabricated drainage body blocks 3; the thin-walled structure The hollow part is a drainage corridor 5 , and the hollow reinforced concrete thin-walled structure is provided with drainage holes 4 running through the interior and exterior of the struc...

Embodiment 2

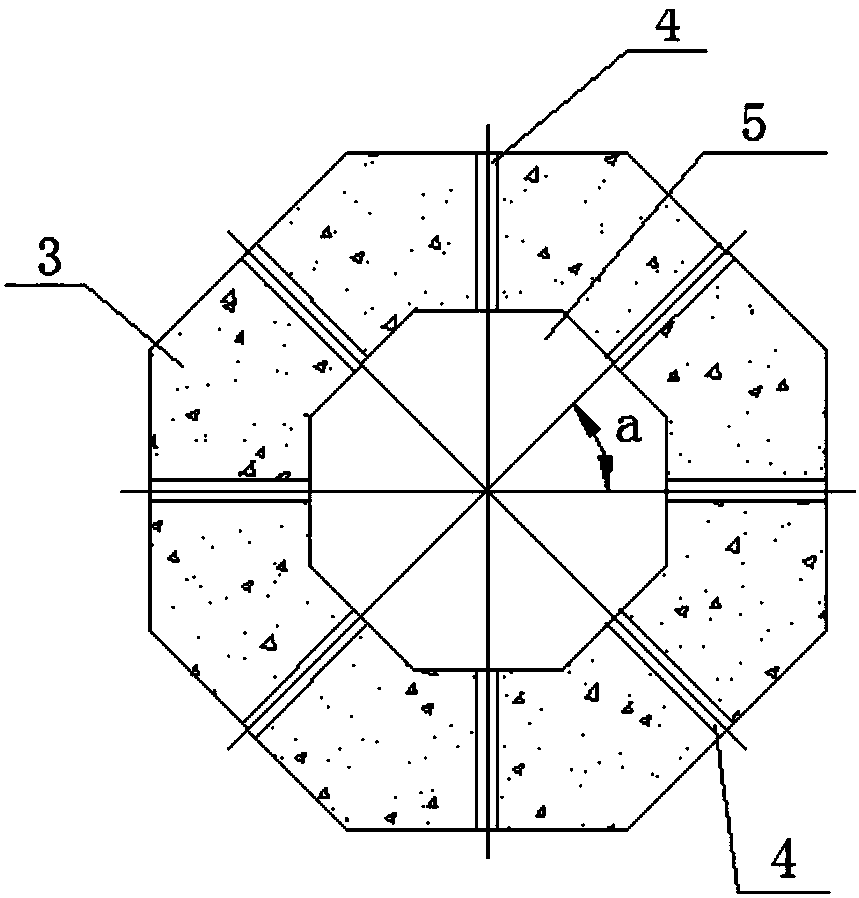

[0039] On the basis of Example 1, such as Figures 3 to 5 As shown, the cross-sectional shape of the prefabricated concrete drainage body 2 is circular, polygonal or gate-shaped. Designed as circular and polygonal, the force condition is good. It is designed in the shape of a city gate, and the space layout is good, which is conducive to the later maintenance and construction.

[0040] The outer diameter of the prefabricated concrete drainage body 2 is 200cm to 400cm. If the outer diameter is greater than 400cm, the weight of the prefabricated concrete drainage body 2 will be heavy, and it will be difficult to transport or hoist on site, and the construction will be inconvenient; if the outer diameter is less than 200cm, the prefabricated concrete drainage body 2 will The space of the internal drainage corridor 5 is small, and it is inconvenient to inspect and overhaul in the later stage, so the outer diameter is selected to be 200cm to 400cm, which not only meets the require...

Embodiment 3

[0045] On the basis of Example 1, such as Figure 3 to Figure 5 As shown, the middle part of each prefabricated drainage body block 3 can be provided with the drainage holes 4, the central angle a between adjacent drainage holes 4 is 45°, and the central angle a is designed to be 45° so that the prefabricated concrete drainage body 2. The drainage holes 4 on the cross section are evenly arranged, and the drainage effect is good.

[0046] The diameter of the drainage hole 4 is 10cm-20cm, which can meet the drainage requirements, has a good enough drainage capacity, and will not reduce the structural strength.

[0047] The drainage hole 4 is filled with a filter protection device 6, which can better protect the fine particles in the rockfill material and can be repaired and replaced later.

[0048] like Figure 7 As shown, the filter protection device 6 includes a geotextile 7 and an elastic material 8 wrapped in the geotextile 7 . The elastic material 8 can be selected from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com