Bottom sealing method for rock foundation pressure-bearing fissure water

A technology for rock foundation and fissure water, applied in the field of foundation treatment, can solve the problems of infiltration damage of sand and gravel permeable cushion, less research on back sealing method, unguaranteed quality, etc. The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

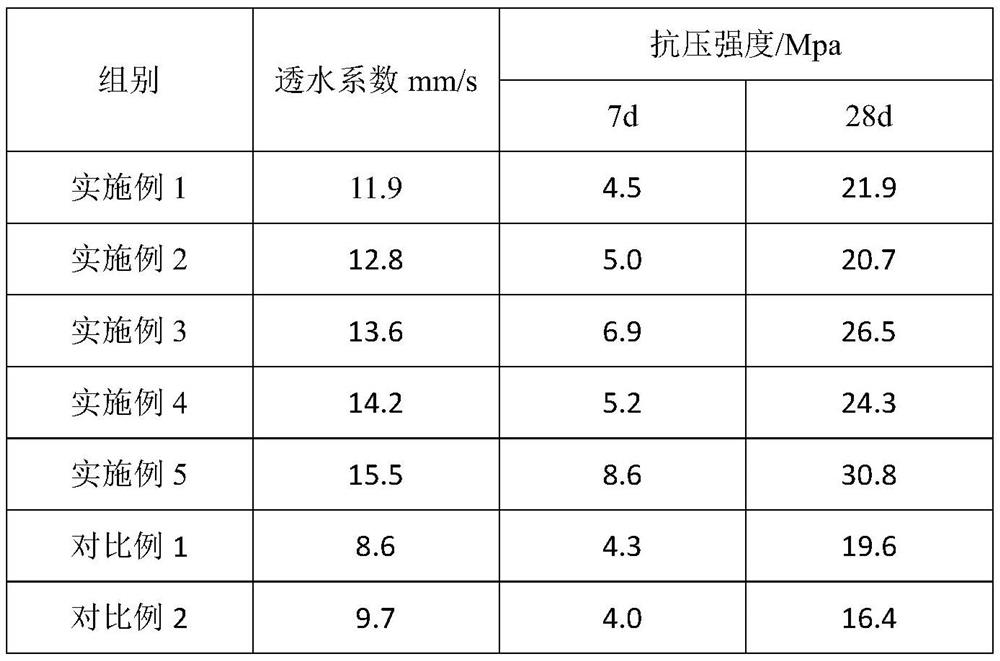

Examples

Embodiment 1

[0033] A method for sealing the bottom of a rock foundation bearing fissure water, comprising the following steps:

[0034] S1, lay permeable concrete on rock foundation, form the permeable concrete layer that thickness is 15cm;

[0035] Wherein, a blind ditch is provided on the rock foundation in step S1; the size of the blind ditch is 10cm×20cm×15cm, and the distance is 2m; graded pebbles are buried in the blind ditch;

[0036] The permeable concrete includes the following raw materials in parts by weight: 200 parts of cement, 600 parts of recycled aggregate, 2.2 parts of water reducing agent and 30 parts of reinforcing agent; the water-cement ratio of the permeable concrete is 0.35;

[0037] Described reinforcing agent is carboxymethyl cellulose, silicon powder and mortar glue that mass ratio is 8:10:1;

[0038] The gradation of the recycled aggregate is:

[0039] 11-13.5mm 60wt%

[0040] 5-8mm allowance.

[0041] S2. Laying an anti-seepage geomembrane on the permeable ...

Embodiment 2

[0044] A method for sealing the bottom of a rock foundation bearing fissure water, comprising the following steps:

[0045] S1, lay permeable concrete on rock foundation, form the permeable concrete layer that thickness is 12cm;

[0046] Wherein, a blind ditch is provided on the rock foundation in step S1; the size of the blind ditch is 15cm×1cm×10cm, and the distance is 1m; graded pebbles are buried in the blind ditch;

[0047] The permeable concrete includes the following raw materials in parts by weight: 300 parts of cement, 900 parts of recycled aggregate, 3.5 parts of water reducing agent and 50 parts of reinforcing agent; the water-cement ratio of the permeable concrete is 0.4;

[0048] Described reinforcing agent is carboxymethyl cellulose, silicon powder and mortar glue that mass ratio is 5:30:1;

[0049] The gradation of the recycled aggregate is:

[0050] 11-13.5mm 80wt%

[0051] 5-8mm allowance.

[0052] S2. Laying an anti-seepage geomembrane on the permeable co...

Embodiment 3

[0055] A method for sealing the bottom of a rock foundation bearing fissure water, comprising the following steps:

[0056] S1, lay permeable concrete on rock foundation, form the permeable concrete layer that thickness is 10cm;

[0057] Wherein, a blind ditch is provided on the rock foundation in step S1; the size of the blind ditch is 12cm×18cm×15cm, and the distance is 1.5m; graded pebbles are buried in the blind ditch;

[0058] The permeable concrete includes the following raw materials in parts by weight: 220 parts of cement, 640 parts of recycled aggregate, 2.8 parts of water reducing agent and 32 parts of reinforcing agent; the water-cement ratio of the permeable concrete is 0.38;

[0059] Described strengthening agent is the carboxymethyl cellulose, silicon powder and mortar glue that mass ratio is 6:15:1;

[0060] The gradation of the recycled aggregate is:

[0061] 11-13.5mm 68wt%

[0062] 5-8mm allowance.

[0063] S2. Laying an anti-seepage geomembrane on the pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com