Double screw rod beam slab controller

A controller and double-screw technology, which is applied to formwork/formwork/work frame, on-site preparation of building components, pillars, etc., can solve the waste of resources, increase the complexity of operation, and difficult to adjust the height of formwork and support system, etc. problems, to achieve the effect of prolonging the service life, suitable for promotion and use, and promoting environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

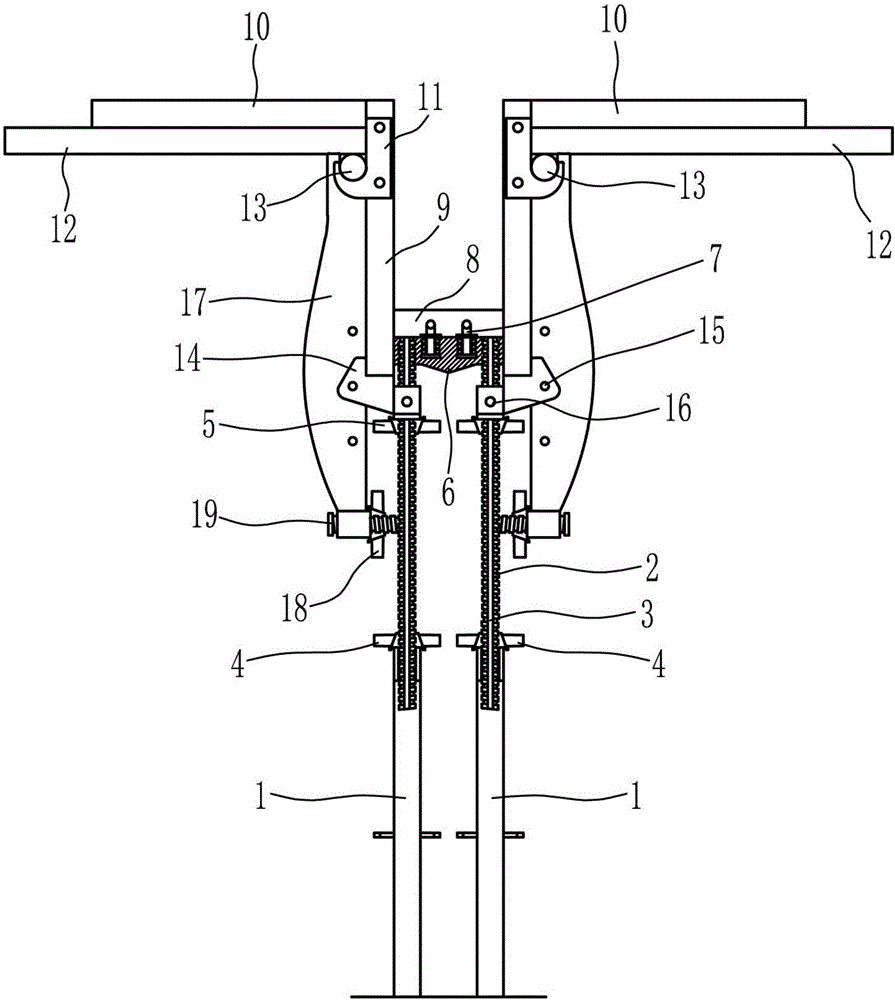

[0019] A double-screw beam-slab controller, such as figure 1 As shown, it includes support frame 1, load-bearing screw rod 2, joist screw nut 4, bracket screw nut 5, beam bottom channel steel 6, beam bottom hook 7, formwork Ⅰ8, formwork Ⅱ9, formwork Ⅲ10, elephant trunk hook 11. Shelf pipe I12, shelf pipe II13, beam support 14, directional screw 16, pressure arm 17, fastening nut 18 and fastening screw 19, and the lower parts of two load-bearing screw rods 2 arranged side by side respectively pass through the joist nut 4 Installed on the support frame 1, the load-bearing screw rods 2 penetrate into the support frame 1 respectively, and the load-bearing screw rods 2 are provided with directional grooves 3, and the upper parts of the load-bearing screw rods 2 are respectively installed with supporting screw nuts 5 and supporting screw nuts. 5 are installed with beam support 14 respectively, and the outside of beam support 14 is provided with hanging hole 15 respectively, and beam...

Embodiment 2

[0021] A double-screw beam-slab controller, such as figure 1 As shown, it includes support frame 1, load-bearing screw rod 2, joist screw nut 4, bracket screw nut 5, beam bottom channel steel 6, beam bottom hook 7, formwork Ⅰ8, formwork Ⅱ9, formwork Ⅲ10, elephant trunk hook 11. Shelf pipe I12, shelf pipe II13, beam support 14, directional screw 16, pressure arm 17, fastening nut 18 and fastening screw 19, and the lower parts of two load-bearing screw rods 2 arranged side by side respectively pass through the joist nut 4 Installed on the support frame 1, the load-bearing screw rods 2 penetrate into the support frame 1 respectively, and the load-bearing screw rods 2 are provided with directional grooves 3, and the upper parts of the load-bearing screw rods 2 are respectively installed with supporting screw nuts 5 and supporting screw nuts. 5 are installed with beam support 14 respectively, and the outside of beam support 14 is provided with hanging hole 15 respectively, and beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com