Compressor and air conditioner comprising same

A technology for compressors and baffles, applied in the field of air conditioning equipment, can solve the problems of reduced contact area between the lower flange and the thrust surface of the crankshaft, abnormal wear of the large end face, unfavorable lubrication, etc., to avoid abnormal wear and reduce production difficulty , the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments.

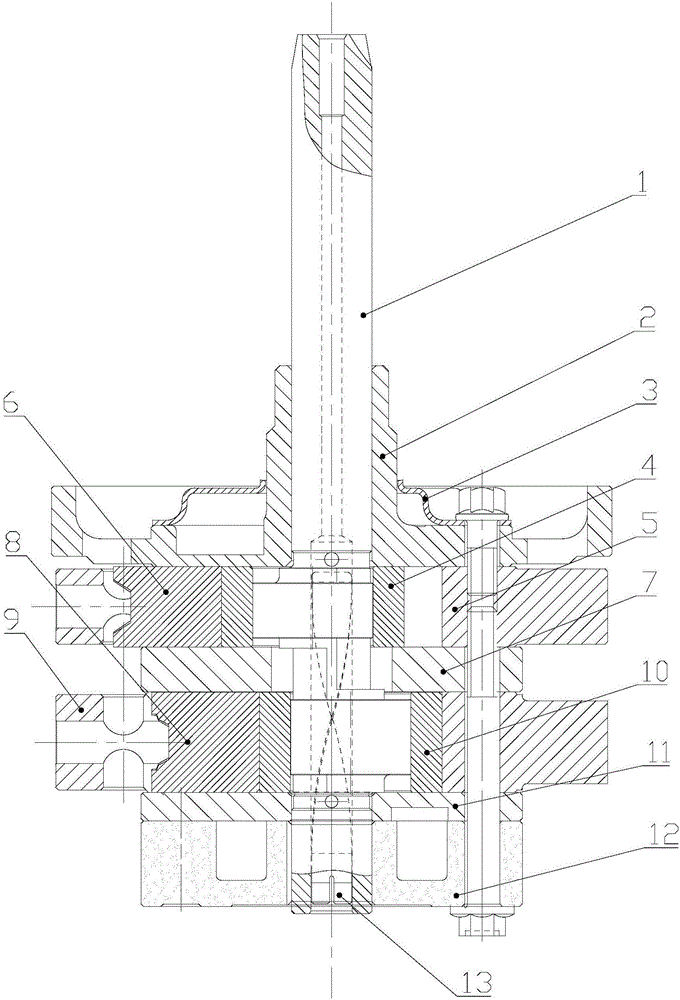

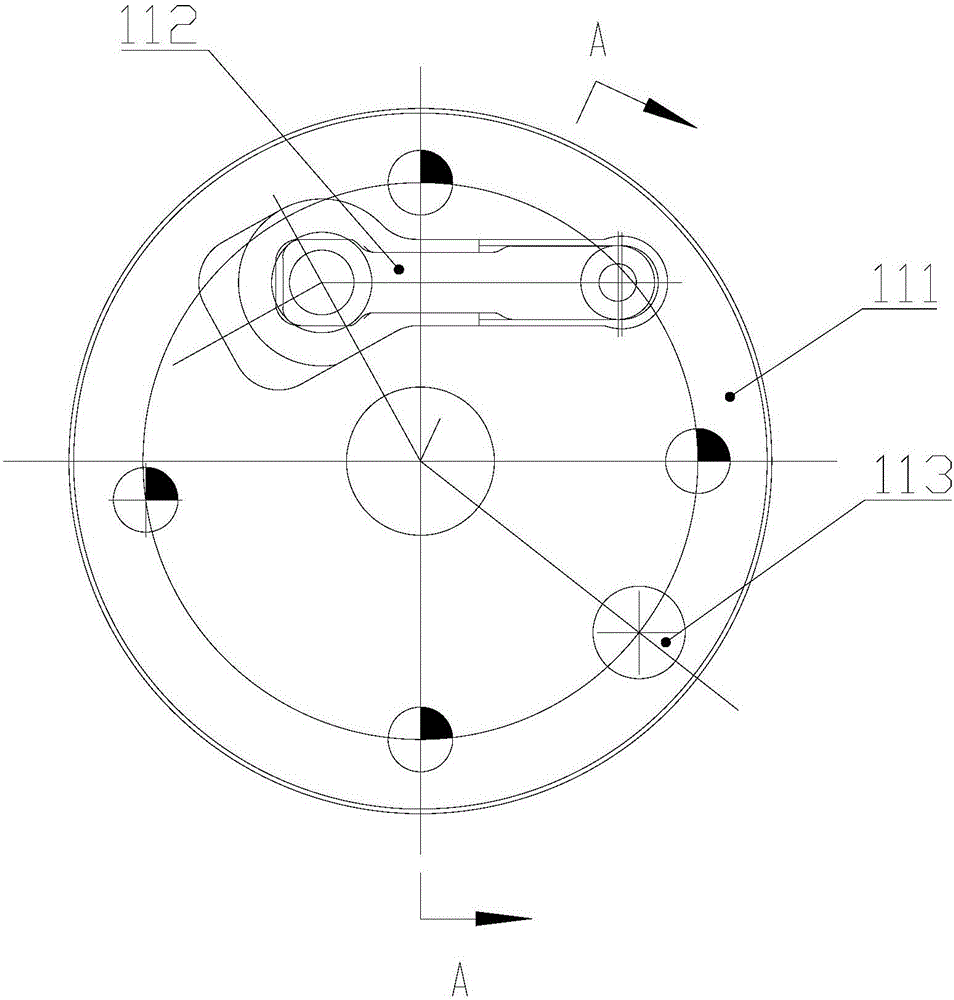

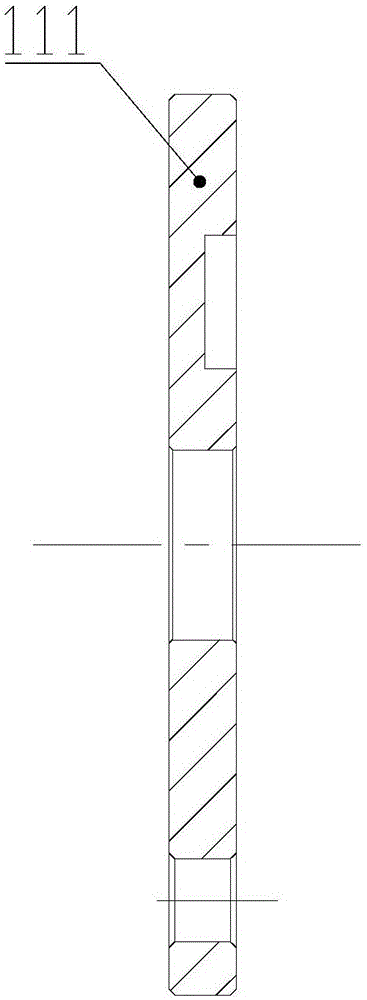

[0026] Such as Figure 1 to Figure 7 As shown, according to the embodiment of the present invention, the compressor includes a crankshaft 1 and a lower flange portion sleeved outside the crankshaft 1. The lower flange portion includes a diaphragm assembly 11 and a lower flange 12, and the diaphragm assembly 11 includes a diaphragm. 111 and an exhaust control structure 112 arranged on the partition 111, and the lower flange 12 is fixedly connected to the partition 111. By arranging the diaphragm assembly 11 on the lower flange 12, the diaphragm 111 replaces the lower flange 12 to contact other components on the crankshaft 1, avoiding abnormal wear of the lower flange 12 and improving the reliability of the compressor. The exhaust control structure 112 is arranged on the partition 111, which can simplify the structure of the lower flange 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com