Novel water surface aircraft water load testing device

A test device and aircraft technology, applied in the direction of measuring device, fluid dynamics test, machine/structural component test, etc., can solve the problems such as the influence of the test piece, the increase of the weight of the test piece, the change of the attitude angle of the model, etc., to achieve Simple and convenient installation and disassembly, simple adjustment of roll attitude, and the effect of improving the accuracy of vertical motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

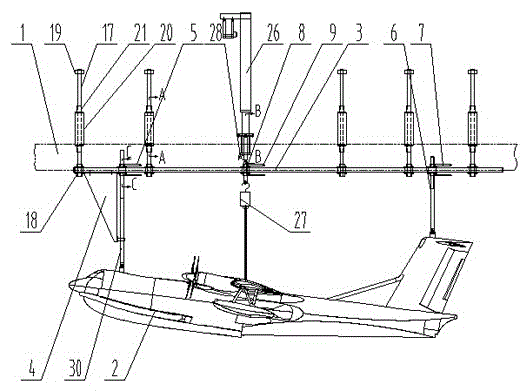

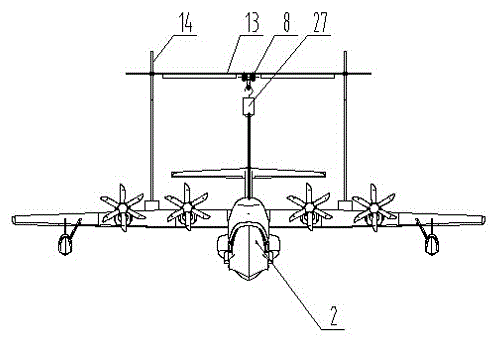

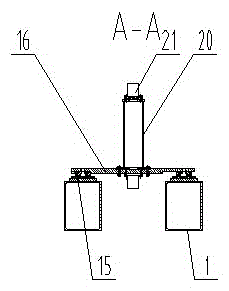

[0031] Such as figure 1 , 2, 3, 4, 5, and 6, the present invention includes an experimental trailer, a central measuring bridge 1 and a test piece 2, and the central measuring bridge 1 is installed on the bottom of the experimental trailer. The aircraft water load test device includes a supporting connecting beam 3, a front and rear supporting connecting assembly, a lifting mechanism, a left and right supporting connecting assembly and a set of linear bearing guiding mechanisms. It consists of a front support link 30, a front support seat 4, a front support threaded handle 5, a rear support link 6 and a rear support threaded handle 7. The bottom of the front support link 30 is rotatably connected to the front of the test piece 2 On the connection fulcrum, the top of the front support link 30 passes through the support connection beam 3, and is locked on the support connection beam 3 by the front support threaded handle 5. The front support seat 4 is in the shape of a right tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com