Testing method for measuring physical properties of soft structure particles and application method of testing device

A test device and physical property technology, applied in the direction of measuring device, particle and sedimentation analysis, particle size analysis, etc., can solve the problems of multiple scattering, weak aggregate damage, inaccurate measurement results, etc., and achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

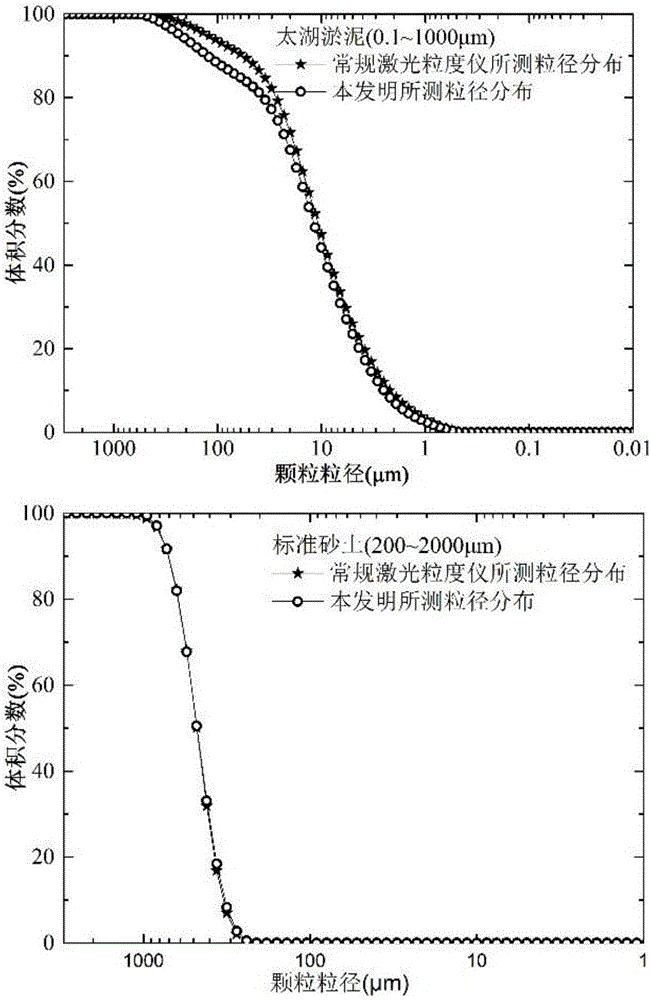

[0031]The conventional rigid particles are measured by using the present invention to verify whether the present invention can be first applied to the measurement of conventional particles. The rigid particles used are: a kind of Taihu Lake dredging silt particles, the silt particles are small, used to compare and verify whether there will be interfering air bubbles during the measurement process; a standard sandy soil, with a large specific gravity, used for comparison and verification Whether it will settle during the measurement process and cause measurement inaccuracy. In this embodiment, the parameters of the test device are set as follows: select a 1.5L Erlenmeyer flask with 750ml of distilled water inside, the speed of the orbital oscillator is set at 280rpm, the particle refraction index of the laser particle size analyzer is set at 1.555, and the absorption index is set at 1.555. 0.1, the refractive index of the dispersant is set to 1.330, the peristaltic pump is set ...

Embodiment 2

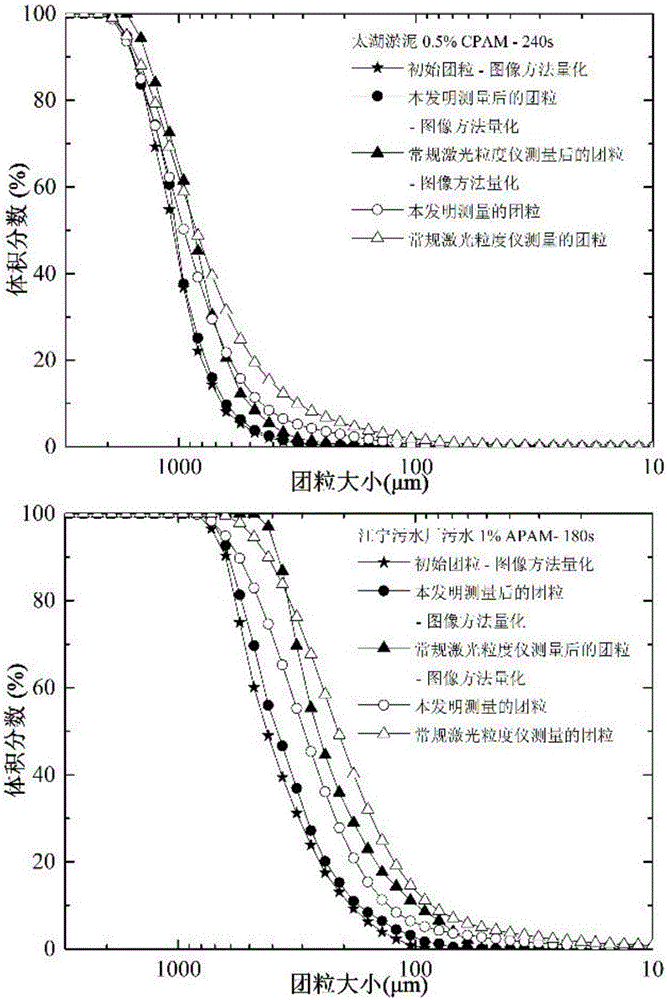

[0034] Two types of flocculated aggregates were measured using the present invention to illustrate the effect of the present invention on the measurement of physical properties of weak structures. The flocculation aggregates used are: the aggregates formed by adding 0.5% cationic polyacrylamide to the dredging sludge particles of Taihu Lake for 240s; In this embodiment, the parameters of the test device are set as follows: select a 1L Erlenmeyer flask with 800ml of distilled water inside, the speed of the orbital oscillator is set to 220rpm, the particle refraction index of the laser particle size analyzer is set to 1.555, and the absorption index is set to 0.1, the refractive index of the dispersant is set to 1.330, the peristaltic pump is set to 5ml / s, and the diameter of the wide-mouth straw is 5mm. Firstly, after the device is debugged and connected, the background value of the dispersion is measured first, and then the measurement is started by adding a sample to the Erle...

Embodiment 3

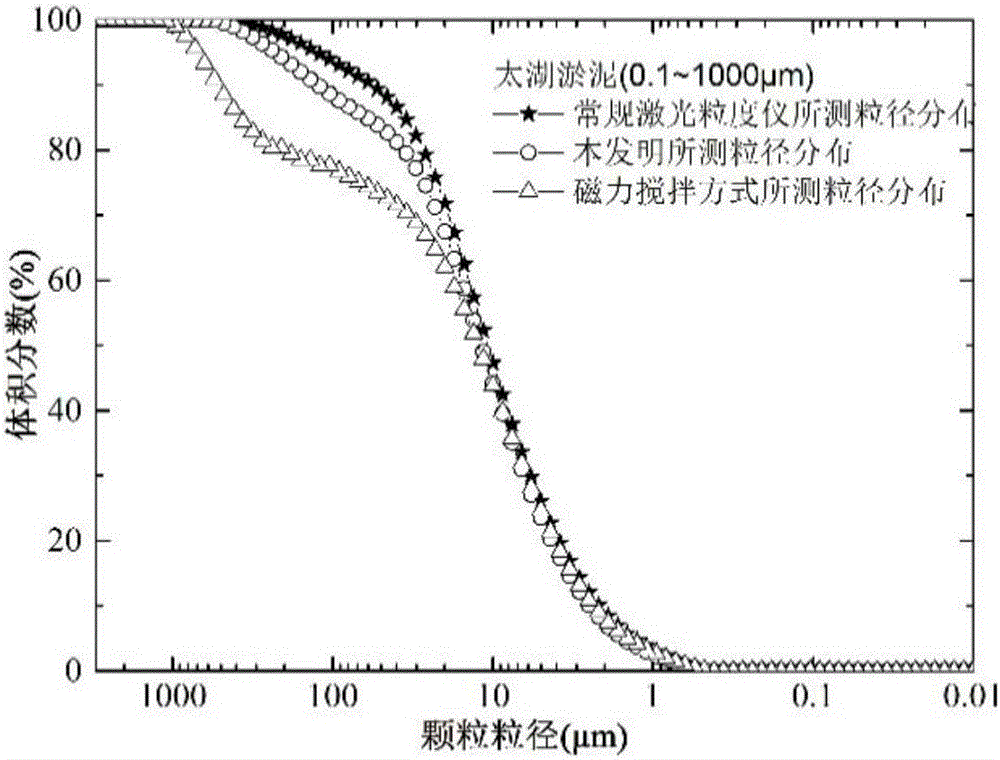

[0037] The present invention is compared with the stirring mode that replaces the orbital oscillator with a magnetic stirrer, and the measurement material is Taihu Lake dredging sludge particles. The present invention uses a 2L Erlenmeyer flask, and the magnetic stirrer stirring speed is set to 250rpm, and the orbital oscillator oscillation speed is 250rpm. Set to 250rpm, the rest of the measurement parameters are the same, the measurement results are as follows Figure 4 shown.

[0038] Depend on Figure 4 It can be seen that the particle size distribution will have a large deviation when the magnetic stirring method is used, which is caused by a large number of air bubbles generated during the magnetic stirring process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com