New type transverse link connection structure

A connection structure and horizontal connection technology, applied in the direction of contact parts, etc., can solve the problems of increased red copper usage, high cost of horizontal connection materials, complex structure, etc., and achieve the effect of simple and easy structure, simple structure and large contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the present invention more obvious and understandable, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

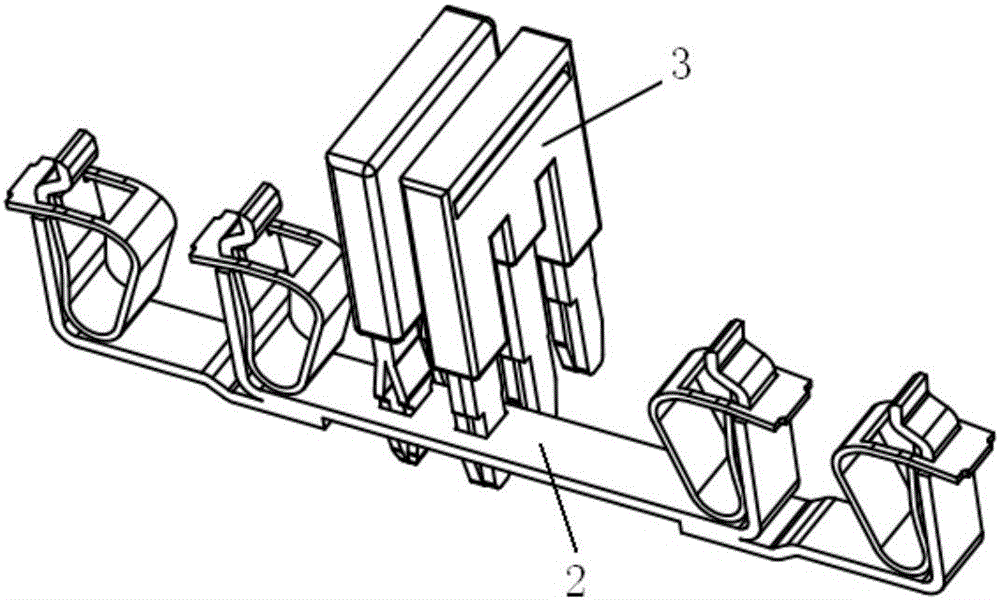

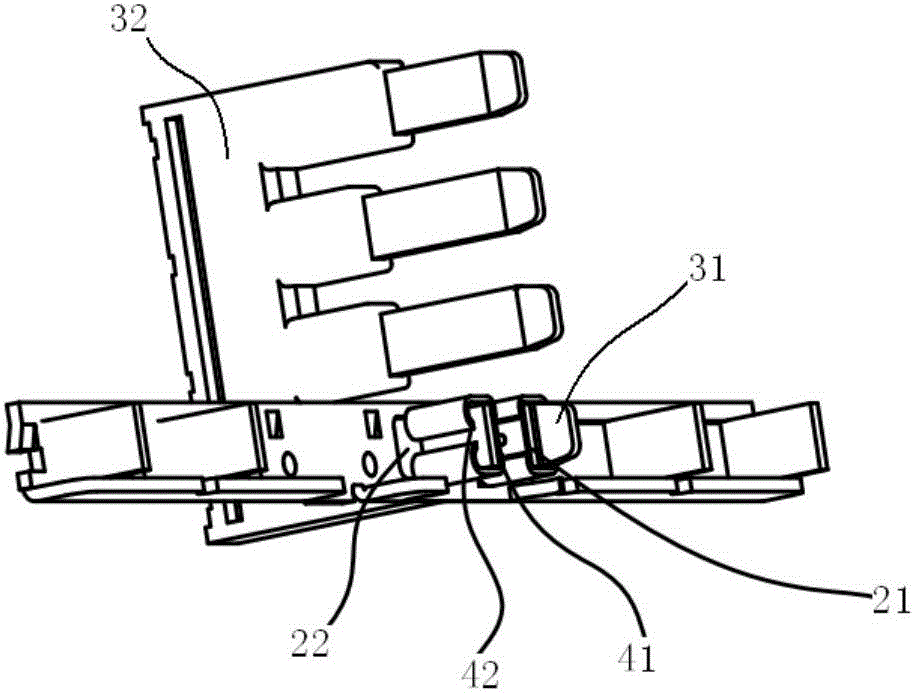

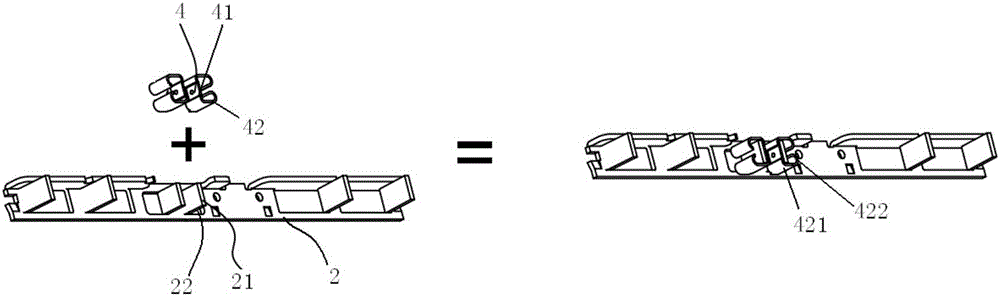

[0026] Such as figure 2 , image 3 , Figure 4 and Figure 5 As shown, a new cross-link connection structure includes a conductive plate 2, a cross-link 3 and a locking elastic piece 4 formed by bending an elastic metal sheet. And the tear hole 22, the cross-link includes a metal pin 31 as a conductive part and an insulating plastic 32 as an operating part; the locking elastic piece includes a side wall 41 and is bent from the same side at both ends of the side wall and then opposite The two elastic clip arms 42 formed by bending and then bending toward the side wall, the locking elastic piece is tightly sleeved on the cantilever, and a jaw is formed between the cantilever and the two elastic clip arms, so The metal pin can be locked and inserted into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com