Tea leaf green-removing device

A greening device and tea technology, which is applied in the tea treatment before extraction, etc., can solve the problems of difficult tea, easy adhesion of tea, inconvenient use, etc., and achieve the effect of increasing moisture content, saving energy, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

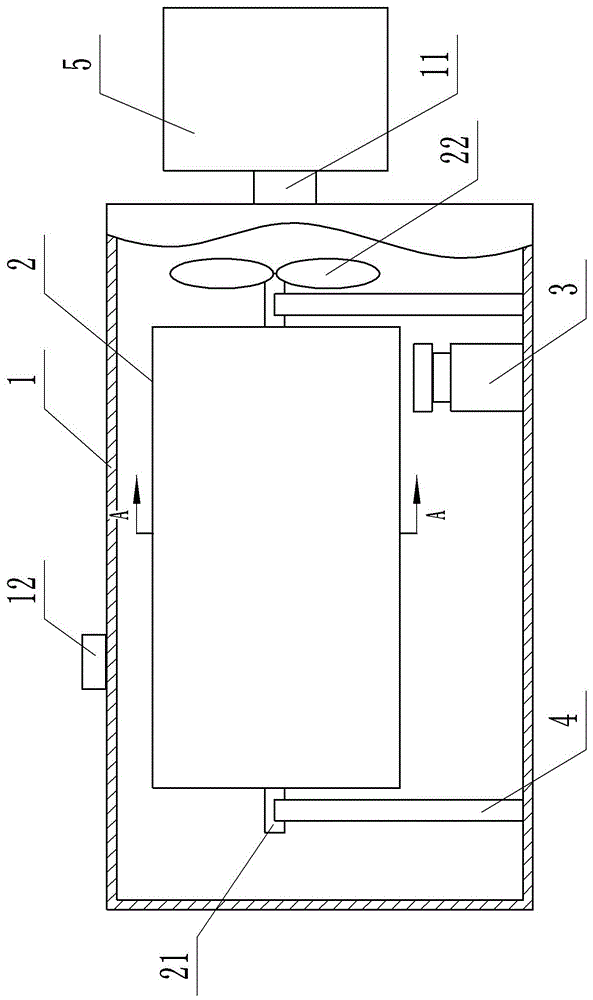

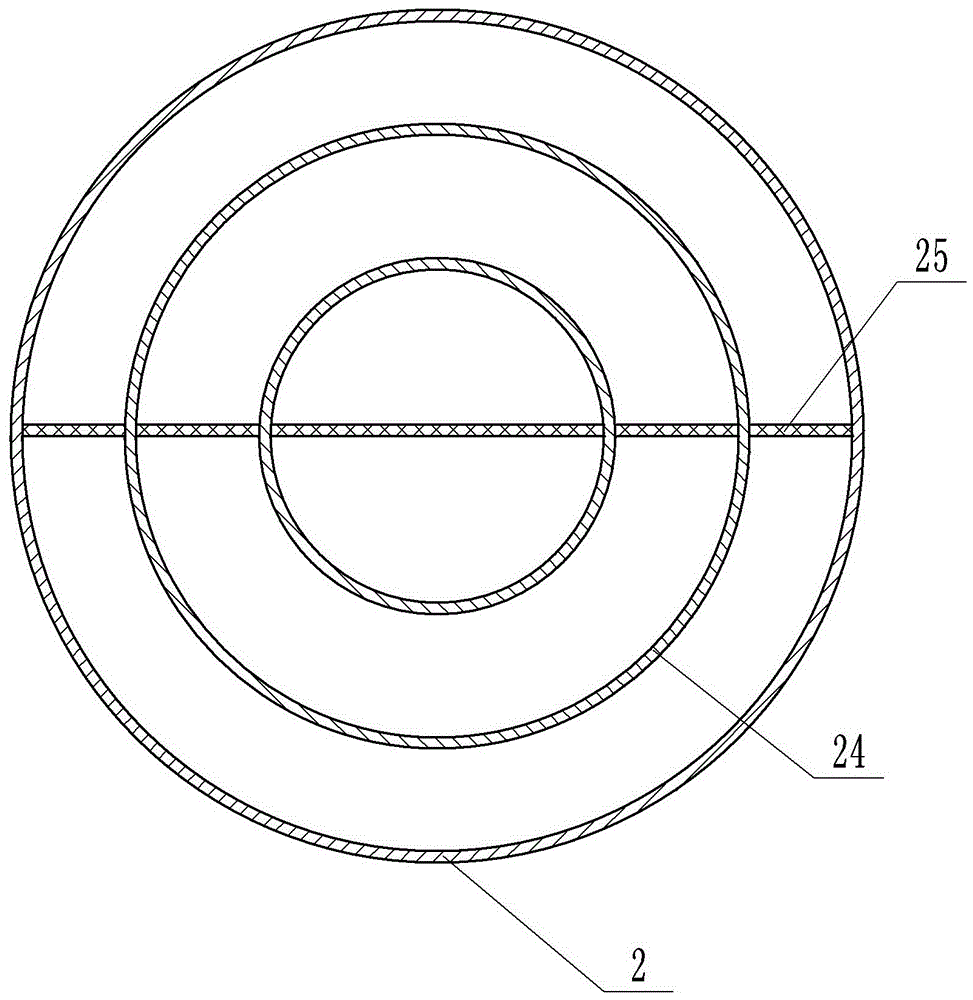

[0017] Such as figure 1 Shown, a kind of tea greening device, a kind of tea greening device, comprises housing 1, and housing 1 is provided with feeding port; Housing 1 is provided with bracket 4 and cylindrical tank body 2, and cylindrical tank body 2 is horizontal Place it on stand 4. The middle part of both sides of cylindrical tank body 2 is welded with rotating shaft 21. The casing 1 is connected with an exhaust port 12 and an air inlet 11, and the air inlet 11 faces the rotating blade 22, and the airflow is passed into the air inlet, and the airflow directly blows on the front of the rotating blade. A hot steam injection device 5 is arranged outside the housing 1, and the hot steam injection device 5 communicates with the air inlet 11, and hot steam is passed into the air inlet 11 to make the rotating blades 22 rotate. Such as figure 2 As shown, the cylindrical tank body 2 is provided with two annular partitions 24, and the two annular partitions 24 divide the cylind...

Embodiment 2

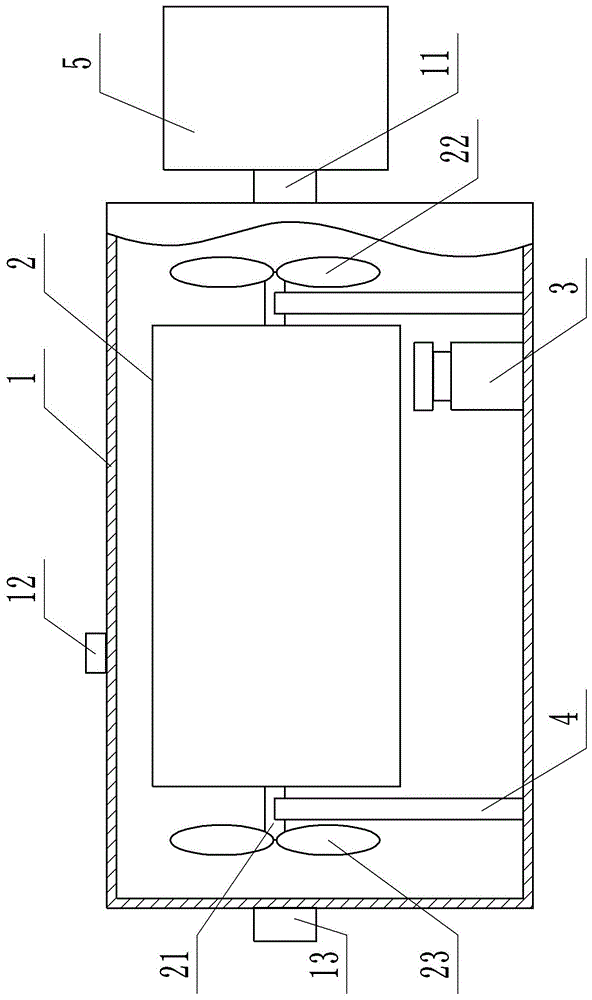

[0020] The difference between the second embodiment and the first embodiment is that the first rotating blade 23 is added on the other side of the rotating shaft 21, and the first air inlet 13 opposite to the first rotating blade 23 is communicated with the casing 1, as image 3 shown. The hot steam is introduced into the casing 1 through the first air inlet 13 , so that the first rotating blade 23 rotates, and the rotating direction of the first rotating blade 23 is the same as that of the rotating blade 22 . When the rotating blade 22 and the first rotating blade 23 rotate in the same direction at the same time, the tea leaves in the cylindrical tank body 2 can be turned over more fully.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com