Tool for horizontally fixing abnormal-shape ABS (Acrylonitrile Butadiene Styrene) composite board

A composite board and fixed board technology, applied in the field of parts positioning, can solve the problems of low work efficiency, poor positioning accuracy, and the existence of reserved edges, etc., and achieve the effect of simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

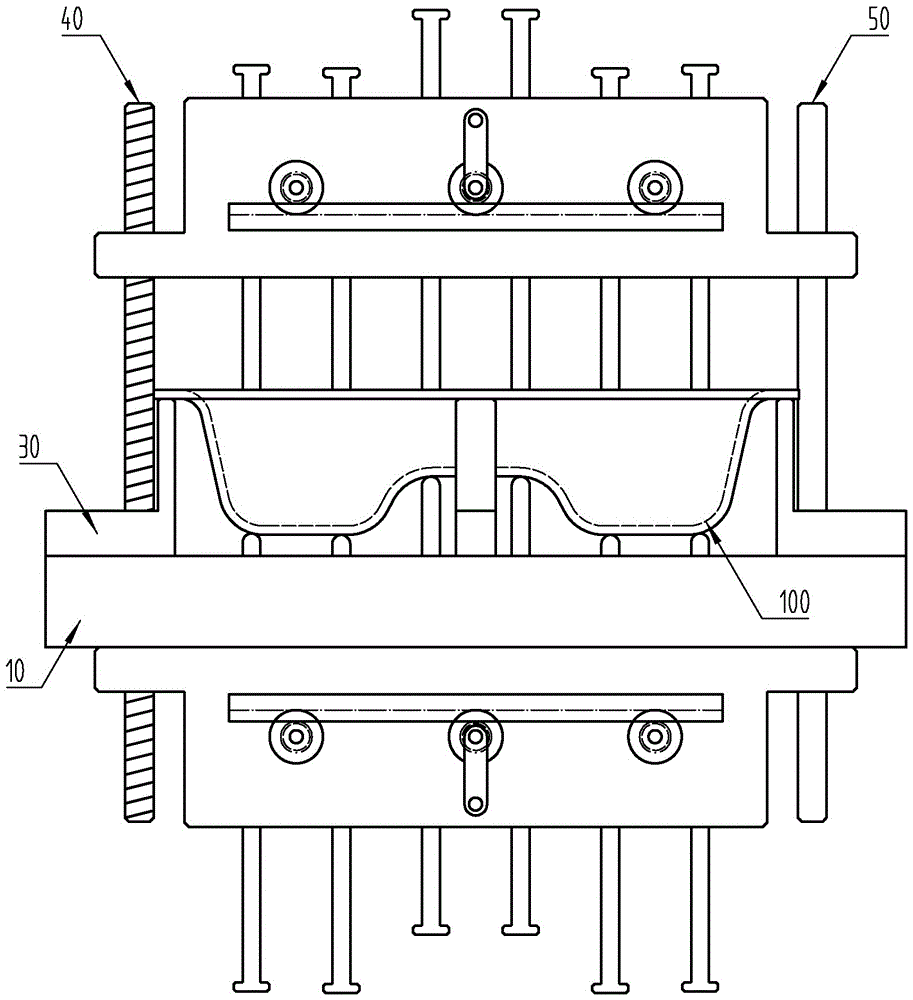

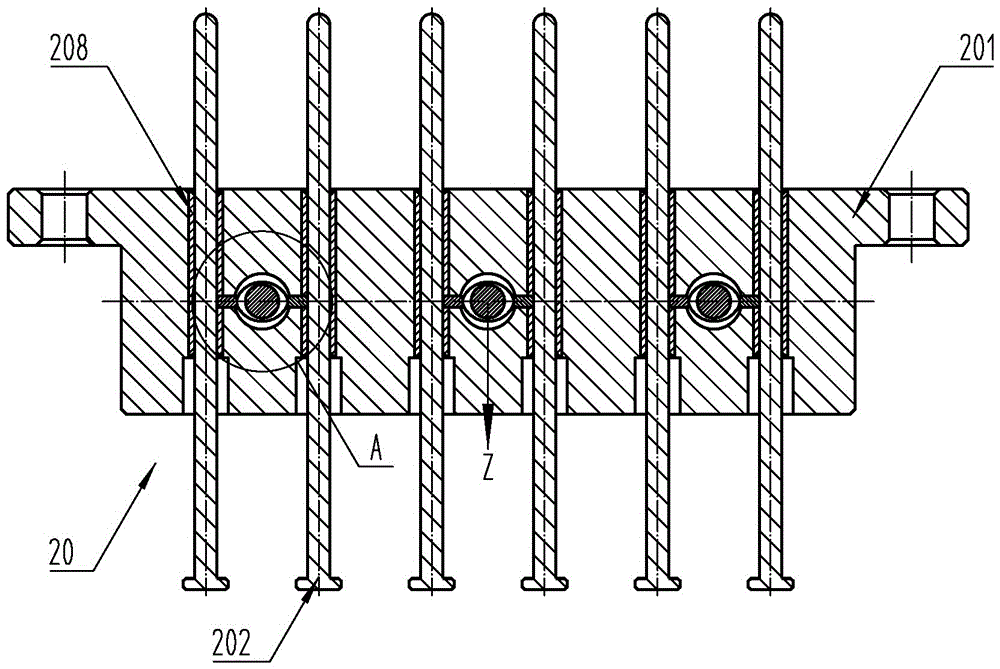

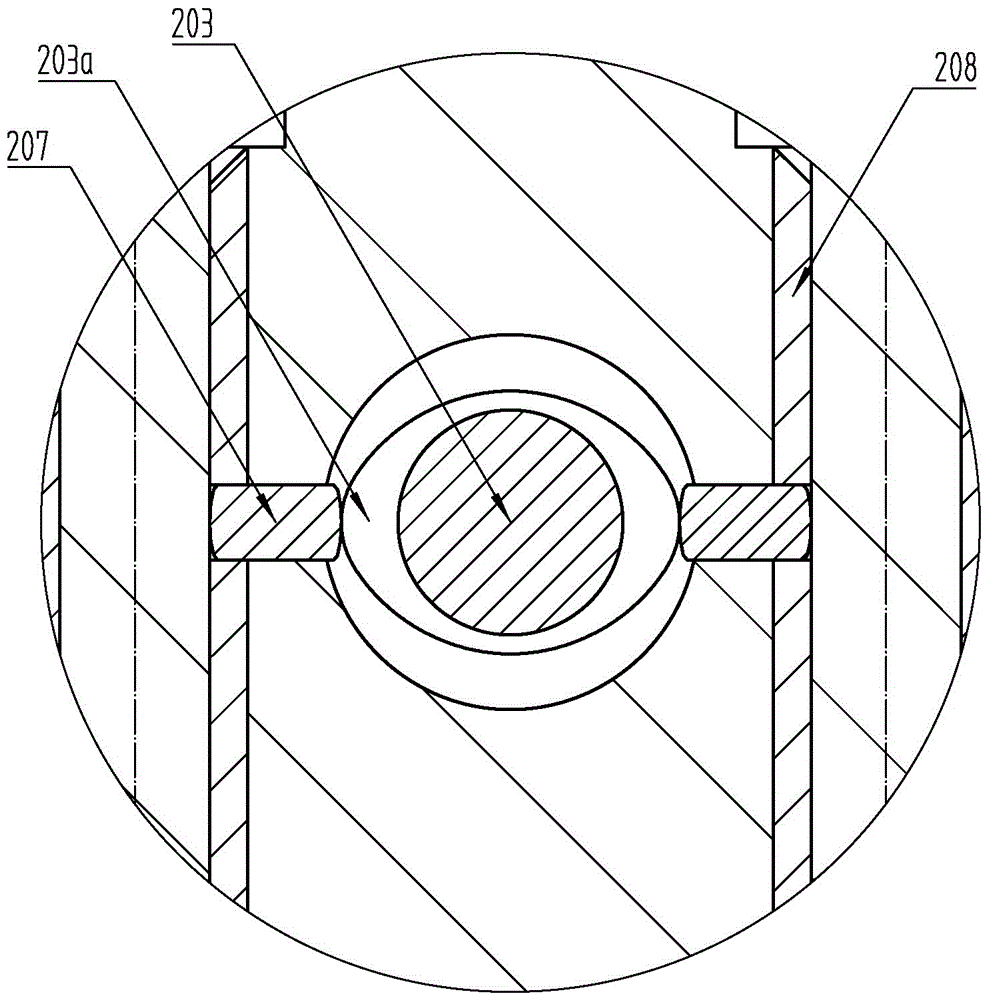

[0024] Such as Figures 1 to 8 As shown, a tool for horizontally fixing special-shaped ABS composite panels includes a workbench 10, a number of support positioning blocks 30 of equal height, and a pair of fixing mechanisms 20 that can move along the first direction. One of the fixing mechanisms 20 is fixed on the workbench 10 , and the other fixing mechanism 20 is adjustable above the workbench 10 through the screw 40 and the guide post 50 . Since the supporting positioning blocks 30 have the same height, the plate 100 can be horizontally positioned above the workbench 10, and the supporting positioning block 30 can be slidably installed on the workbench 10 to be close to or away from the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com