Novel viscous bulk material band extrusion machine

A block material and extruder technology, which is applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of high work requirements of extruders, achieve the effect of solving feeding problems and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with specific embodiment, further set forth the present invention:

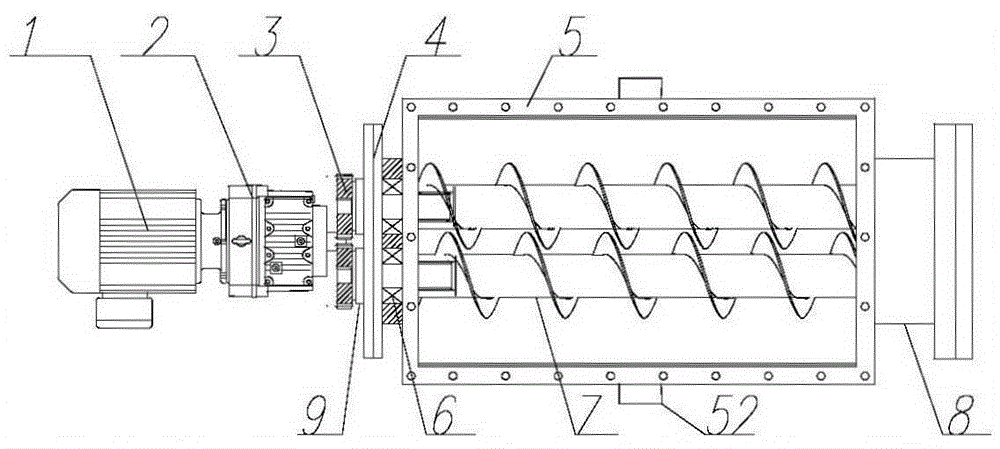

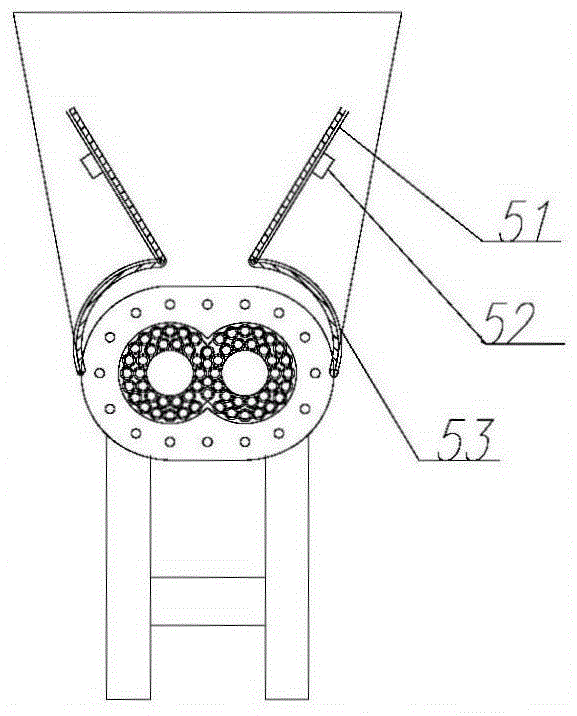

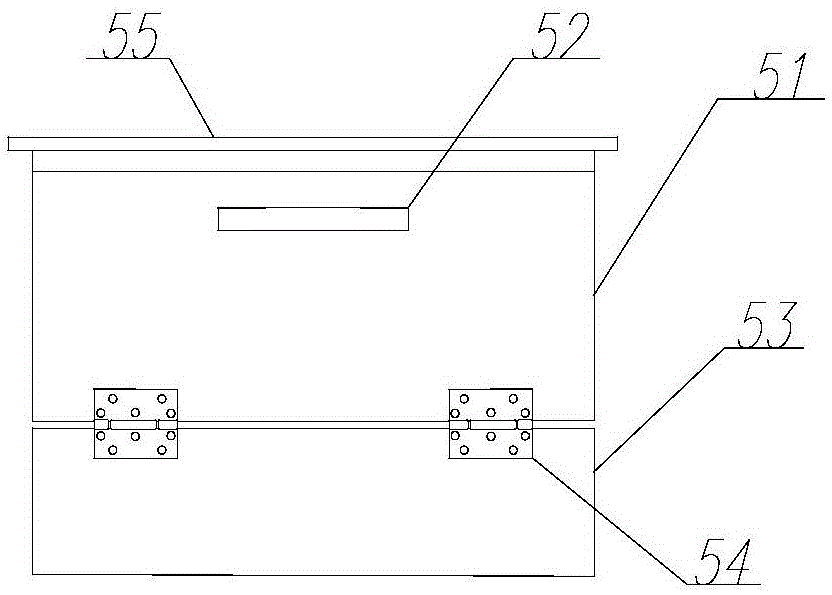

[0017] Such as figure 1 , 2 , Shown in 3, a kind of novel viscous bulk material extrusion machine of the present invention comprises motor 1, speed reducer 2, gear 3, flange plate 4, blanking working room 5, screw rod 7 and extrusion template 8. The present invention selects two screw rods 7 for use, and one end is equipped with gear 3 and is connected by bearing 6, bearing end cover 9, flange 4, and the other end is connected by bearing 6 and is placed in blanking studio 5; blanking studio 5 includes The plane side wall 51 and the arc side wall 53, one end of the arc side wall 53 is fixed on the bottom of the blanking studio 5, and the other end is connected with the plane side wall 51 by a hinge 54.

[0018] An idler gear is housed on the main shaft of motor 1, changes the steering of two screw rods by intermeshing with the gear 3 at one end of two screw rods 7, so that the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com