Process for starting anaerobic ammonia oxidation through AB-ASBRs

An AB-ASBR, anaerobic ammonia oxidation technology, applied in the field of sewage sludge biological treatment, can solve the problems of high operating cost, low treatment efficiency, unstable flora advantage, etc., to improve treatment efficiency, reduce treatment costs, The effect of saving processing costs and floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

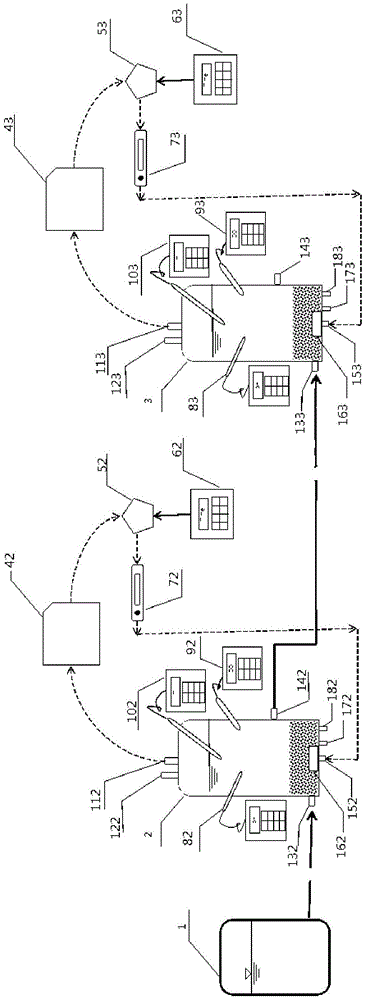

[0017] The method of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] AB-ASBR reactor of the present invention starts the technology of anaerobic ammonia oxidation, comprises the following steps:

[0019] 1. Start the ASBR reactor in the front and back sections: use the return sludge of the urban sewage treatment plant as the inoculation sludge, inject it into the ASBR reactor in the front and back sections, the sludge concentration is 3000-4000mg / L, and the initial volume load is 0.2 gCOD / (L·d) culture and add an appropriate amount of flocculant polyacrylamide to cultivate anaerobic granular sludge under medium temperature conditions; among them, Methanosarcina and anammox bacteria were cultivated in the ASBR reactor 2 in the front section For the granular sludge of dominant bacteria, the granular sludge with methanothrix and anaerobic ammonium oxidizing bacteria as the dominant bacteria is cultivated in the rear ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com