Automatic feeding device for magnet parts

A technology of feeding device and magnet, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of magnets returning to products, difficult separation, low efficiency, etc., so as to achieve short operation time, solve feeding problems, and improve efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

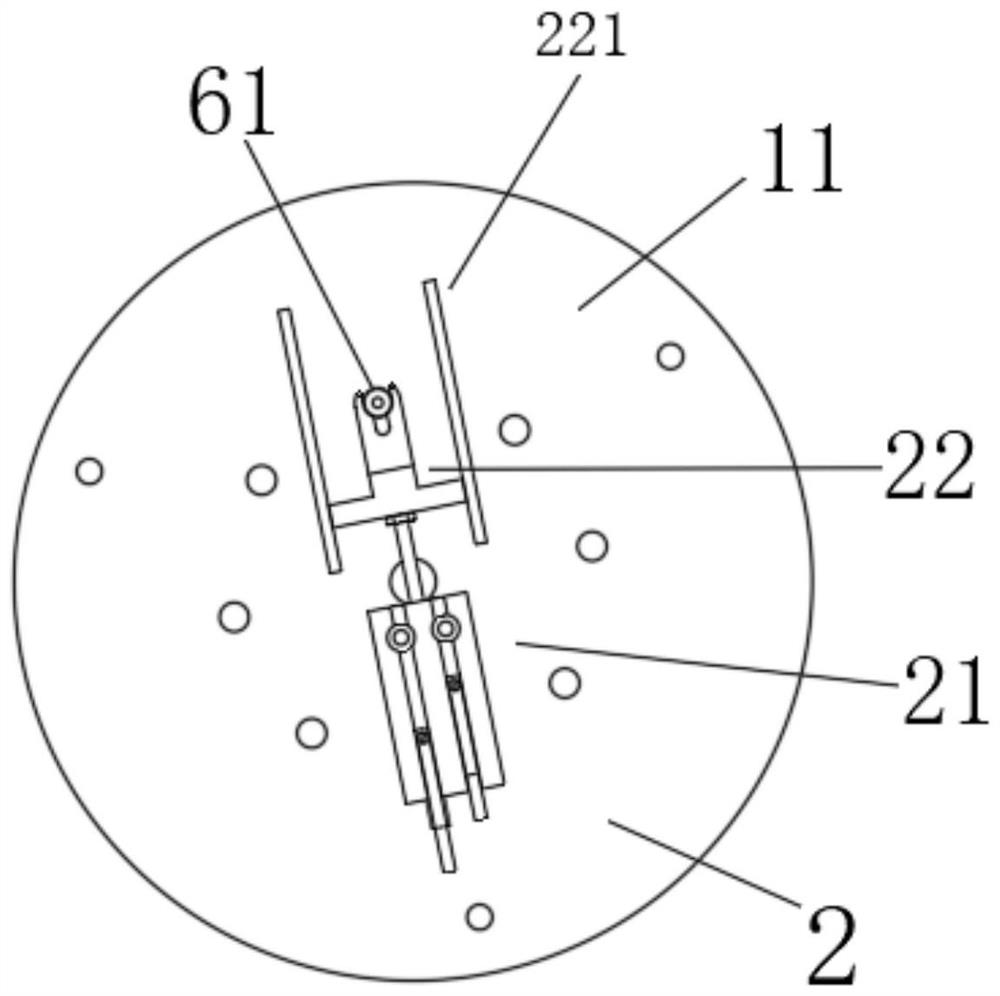

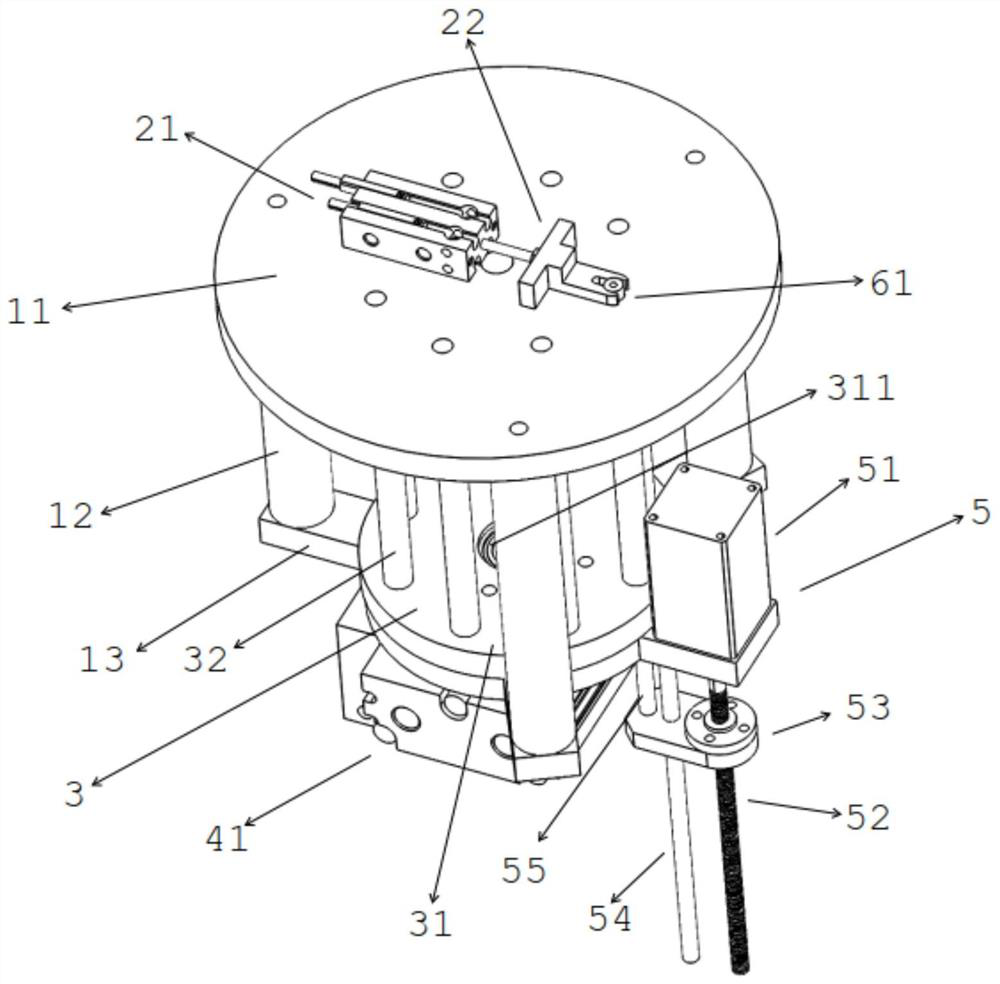

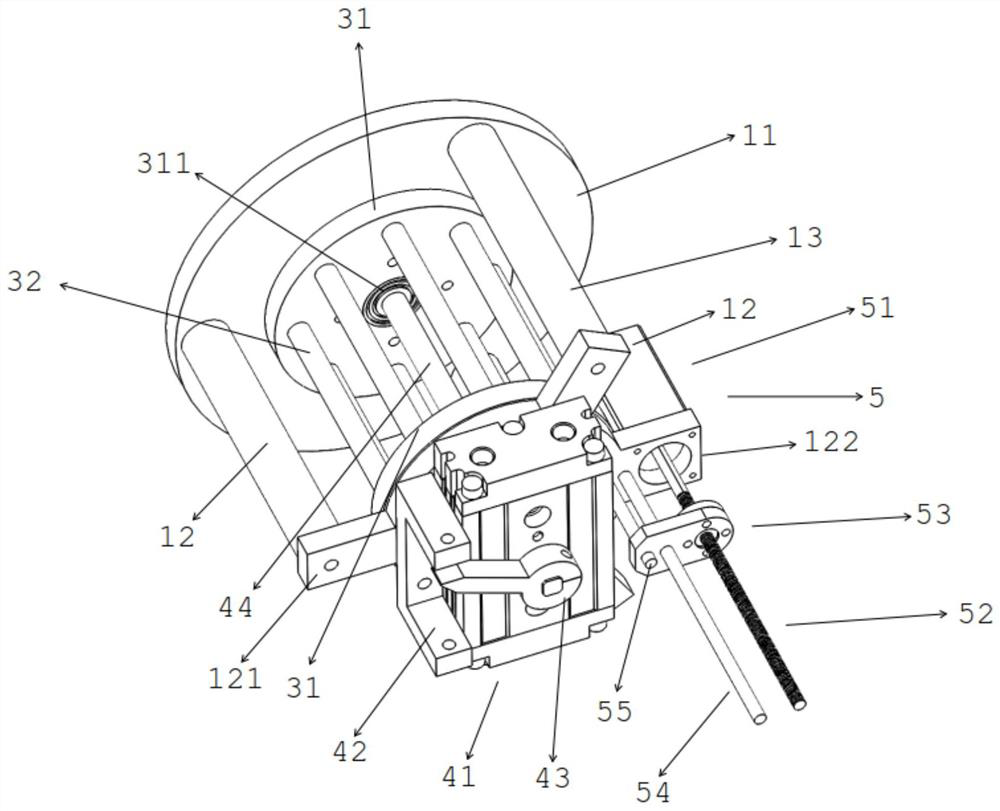

[0040]Insert the magnet string 6 into the non-magnetic stainless steel round tube 32 of the squirrel cage mechanism 3 respectively, and then the stepping motor 51 drives the motor screw 52 to rotate forward, thereby driving the screw nut 53 to move upward in real time, and driving the moving top in real time. The rod 55 moves upwards, and the moving ejector rod 55 moves up in real time, and the thickness of a magnet 61 protrudes from the surface of the upper circular support plate 11, and then the stepping motor 51 stops driving. After the ejected magnet 61 is removed, the The stepping motor 51 moves up one magnet 61 thickness, and the moving ejector rod 55 pushes out the next magnet in real time, and repeats the action in this way, and the magnet string 6 in the whole non-magnetic stainless steel round tube 32 is pushed out one by one. , when the last magnet 61 is ejected and removed, the stepper motor 51 is reversed and reset, so that the motor screw 52 and the screw nut 53 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com