Electric multistage actuating cylinder retracting and releasing locking device

A locking device and actuating cylinder technology, applied in the chassis and other directions, can solve the problems of complex inner cavity shape, damage to the transmission mechanism, and locking failure, etc., and achieve the effects of simple processing, high reliability, and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

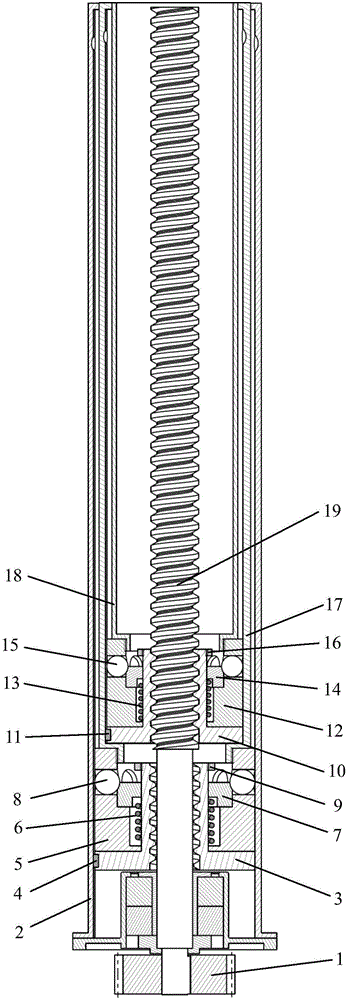

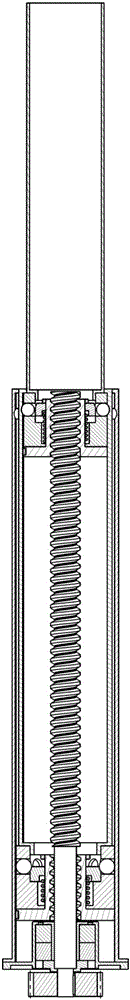

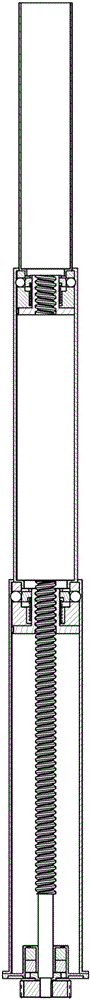

[0018] The invention provides an electric multi-stage actuator retractable locking device, the structure of which is as follows: figure 1 As shown, the expanded structure of the inner cylinder is as follows figure 2 As shown, the fully expanded structure is shown as image 3 As shown, it includes an outer cylinder 2, an intermediate cylinder 17, an inner cylinder 18, a lead screw 19 and a two-stage steel ball lock mechanism installed outside the lead screw 19. It is characterized in that: the two-stage steel ball lock mechanism includes a superior steel ball lock mechanism. Ball lock mechanism and lower steel ball lock mechanism.

[0019] The lower-level steel ball lock mechanism includes the lower sliding sleeve 5 (such as Figure 4 shown), the lower unlocking sleeve 3 (as shown Figure 5 shown), the lower locking slider 7 (as shown Figure 6 shown), the lower limit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com